Analysis of Mechanical Characteristics of High Slope of Embankment Reinforced by Geogrid

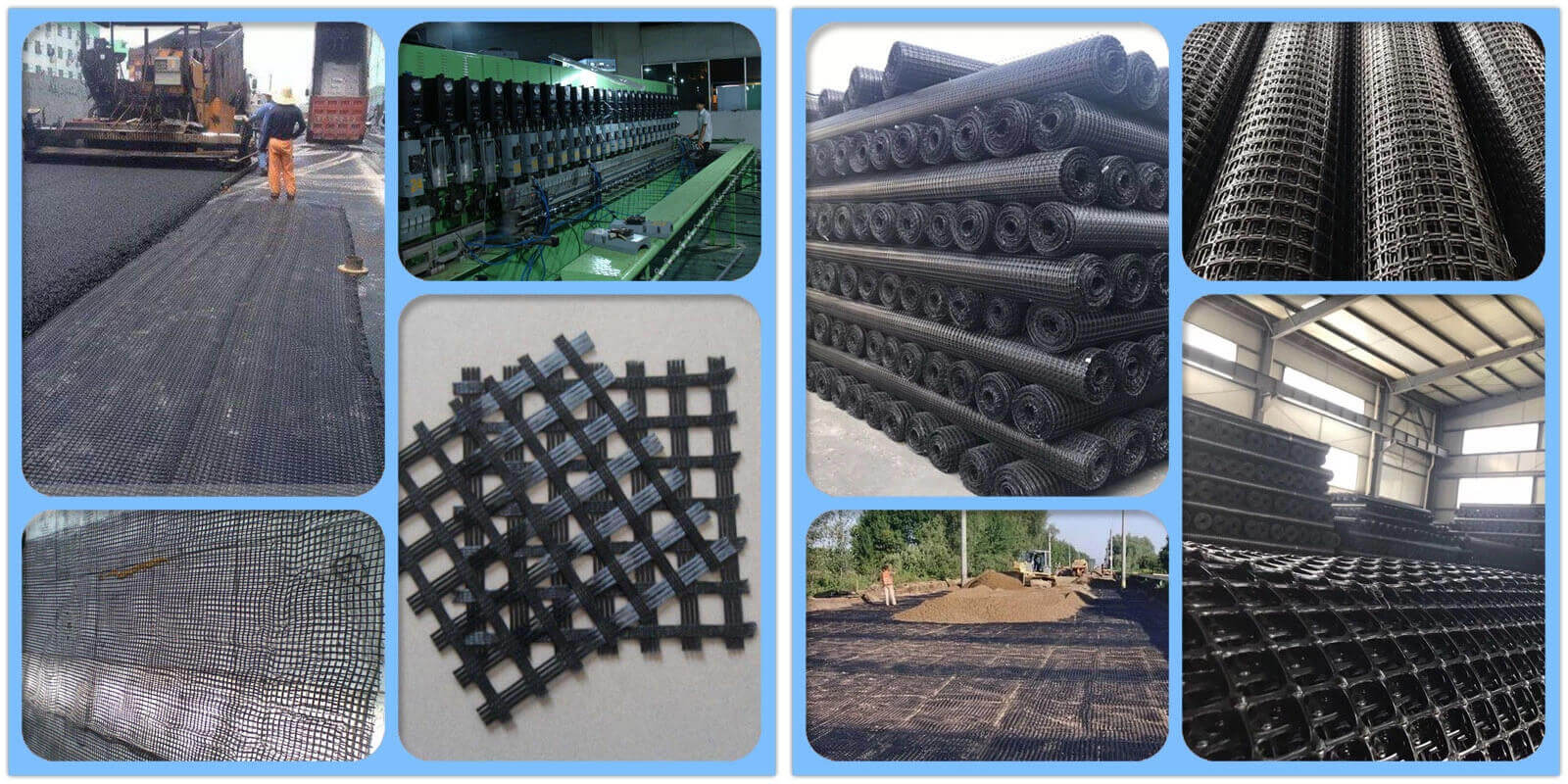

Abstract: Taking the wholesale biaxial geogrid in a road engineering to reinforce the high slope of the embankment, the influence of the internal force and filling height of the reinforced materials in different layers on the tensile force of the reinforced materials was analyzed by Madis finite element software. The results show that the tensile force of each layer of high quality biaxial geogrid increases first and then decreases with the increase of the slope distance; the stress of the reinforced material depends on the stress at the slope where it is located. The biaxial geogrid manufacturers have a significant effect on the reinforcement of the slope, indicating that the biaxial geogrid for sale reinforcement scheme of the high slope of the embankment is reasonable.

Keywords: high embankment slope; high quality biaxial geogrid; mechanical properties; reinforcement effect

introduction

The artificially constructed high embankment of soil embankment has received extensive attention in the study of slope stability. Due to the multiple factors such as the nature of the fill, the construction method, the external load, and the environmental impact, the damage mechanism of the soil embankment slope is more complicated. Therefore, studying the reinforcement effect of high embankment slope is of great value to solve the slope stability problem.

In the slope reinforcement method, the reinforced soil is a common method to improve the stability of the embankment slope, that is, the deformation and settlement of the subgrade slope are effectively suppressed by the frictional effect of the geotechnical material and the roadbed filling. The reinforcement method has low cost and simple construction operation and is often adopted by the construction unit. However, the reinforcement effect of the wholesale biaxial geogrid during construction is very critical, directly affecting the stability of the slope and construction costs.

Based on this, this paper will use the biaxial geogrid for sale in road engineering to reinforce the high slope of the embankment as an example. The Madis finite element software is used to analyze the influence of internal force and filling height variation of the reinforced materials located in different layers on the tensile force of the reinforced materials. Study the reinforcement effect of the slope project and verify the reliability of the reinforcement scheme.

1. Project Overview

The project is a new road section. The route is designed according to the standard of Grade 2 road. It is distributed along slopes and valleys. The length of the line is 21.32km, the design speed is 50km/h, the roadbed width is 16.5m, and the road width is 14.5m. The route consists of 4 bridges, 38 culverts, 23 deep roads, and 19 high fills. In this paper, K10+340 high fill is selected as the research object, and the slope height is about 26.8m. The filling area is located in the low valley of the valley and the gully. The planting soil and silty clay are distributed in the shallow surface layer, and the fourth layer is the new system of plastic and hard plastic silty clay.

After the slope stability analysis, it is found that the safety factor of the slope does not meet the requirements of the specification. According to the design scheme, the high slope of the embankment adopts the masonry stone slope protection + grade 3 grading (the ratio of slope ratio from slope foot to slope top is 1:1.5, 1:1.5, 1:1.5) + wholesale biaxial geogrid reinforcement measures Carry out slope reinforcement design.

2. Reinforced soil reinforcement design

2.1 Design content

The content of the reinforced earth reinforcement design usually includes structural design, structural calculation, construction drawing, construction technology, and project budget. Among them, the content of structural calculation is mainly the internal stability analysis of reinforced materials and the external stability analysis calculation of reinforced structures. The main content of the internal stability analysis is the calculation of the pullout force and tensile strength of the reinforced material, which is used to determine the location, quantity, and arrangement of the lacing so that the reinforced soil can finally work synergistically. The external stability analysis usually refers to the basic settlement analysis, and the Swedish strip method is used to check the stability of the reinforced soil slope.

2.2 Design steps

The steps for reinforced earth reinforcement design are:

(1) Preliminary selection of suitable reinforced materials to determine the layout of the initial lacing material.

(2) Check the overall stability of the slope after reinforcement.

(3) According to the stability calculation result, adjust the form of the lacing in step 1, and repeat step 2 until the calculation meets the design requirements and economic requirements.

2.3 reinforced soil design results

The slope is designed with a grade 3 grading (1:1.5, 1:1.5, 1:1.5 slope from the foot to the top of the slope). The slope height of the 3rd-grade slope is 7.8m, 9m, 10m from top to bottom, and the width of each platform is 1.0m. It is proposed to use two-way composite wholesale biaxial geogrid material for reinforcement treatment. The design parameters are shown in Table 1.

The determined reinforcement scheme is a composite biaxial geogrid for sale material with 11 layers of 12 m long and 11 layers of 15 m long with a spacing of 0.8 m between the first and second stages; the third stage slope is 1 m and 6 layers are 8 m long. Composite high quality biaxial geogrid material. The finite element analysis method of Midas is used to calculate the slope after reinforcement, and the displacement cloud map of the reinforced soil slope is shown in Fig. 1. As can be seen from Figure 1, the maximum horizontal displacement is 4.34 mm. At the same time, the stability calculation of the slope is carried out, and the calculation of the stability of the reinforced soil slope is shown in Fig. 2. It can be seen from Fig. 2 that the overall stability safety factor of the slope body is 1.369, which is greater than the standard value of 1.3 ((JTGD30-2015) “Highway Roadbed Design Code”), which meets the design specifications. This also shows that the proposed reinforcement scheme can meet the requirements.

3. Geogrid internal force analysis

After the embankment slope is layered and filled, the tensile stress distribution of the reinforced material of the slope is analyzed. The Midas finite element analysis software was used for numerical simulation analysis, and the contact surface unit of soil and reinforced materials was selected to simulate the interaction of reinforced materials and filling materials. The tensile stress distribution of the wholesale biaxial geogrid in the embankment slope is shown in Figure 3.

In order to obtain the distribution law of biaxial geogrid manufacturers tensile stress, the paper calculates the tensile force of each layer of biaxial geogrid for sale in the slope by software. The tensile stress distribution of the biaxial geogrid factory price in each layer of the third-grade slope is shown in Fig. 4.

Figure 4 (a) and 4 (b) is the gradient curves of the high quality biaxial geogrid of the first and second-grade slopes after the completion of the slope filling construction. The biaxial geogrid manufacturers set in the two types of slopes are all 11 layers, and only the even layers are used to investigate the internal force variation of the biaxial geogrid factory price. As can be seen from the data in Figures 4(a) and 4(b), as the number of layers of reinforced material increases, the tensile force of the biaxial geogrid factory price gradually increases. This shows that the biaxial geogrid manufacturers reinforcement effect placed on the upper part of the slope is more obvious, and the change of the tensile force of the reinforcement is mainly concentrated in the second half of the biaxial geogrid factory price. Figure 4(c) shows the variation of the biaxial geogrid factory price tensile force of the third-grade slope after the completion of the slope filling construction. There are 6 layers of wholesale biaxial geogrid in the slope. As the number of grid layers increases, the tensile force of the first 5 layers of biaxial geogrid for sale gradually decreases. This indicates that the high quality biaxial geogrid reinforcement effect provided in the lower part of the slope is more significant. In summary, the tensile force of each layer of biaxial geogrid manufacturers in the slope increases first and then decreases with the increase of the slope distance, and there is a maximum value.

By comparing the high quality biaxial geogrid tension of the 1st, 2nd and 3rd grade slopes, it can be seen that the first and third grade slopes are different due to the different number of layers of the biaxial geogrid manufacturers, and the distribution of the biaxial geogrid manufacturers is different in the whole slope, indicating that the reinforcement is The force of the material depends on the amount of stress at the slope on which it is located. According to the tensile curve of the biaxial geogrid factory price of the 1st and 2nd grade slopes, it can be seen that the biaxial geogrid for sale tensile value far from the slope area is larger, but the actual soil shear deformation of this part is more obvious, and with Increased shear deformation is highly likely to cause sliding damage in this area.

4. The effect of filling height change on the tensile force of reinforced materials

In order to study the variation law of the tensile force of the high quality biaxial geogrid with different filling heights, the filling and construction process of the first, second and third-grade slopes are respectively formulated into three construction stages. Among them, the filling height of the first-grade slope is 10m, the filling height of the second-grade slope is 9m, and the filling height of the third-grade slope is 7.8m. Through the force analysis of the biaxial geogrid factory price, the tensile distribution curves of the 5th wholesale biaxial geogrid in the 1st and 2nd-grade slopes in different construction stages are obtained. The distribution of the fifth-layer high quality biaxial geogrid tensile force of the first-stage slope is shown in Fig. 5. The distribution of the fifth-layer biaxial geogrid manufacturers of the second-stage slope is shown in Fig. 6.

It can be seen from Fig. 5 and Fig. 6 that as the height of the slope filling increases, the position of the maximum value of the biaxial geogrid for sale in the first and second-grade slopes gradually approaches the end of the rib, indicating the biaxial geogrid for sale The effect of reinforcement is more significant. In addition, with the increase of the height of the upper part of the slope, the tensile force of the reinforcement gradually increases and the overall increase tends to be concentrated in the latter part of the reinforcement.

5. Conclusion

Taking the high slope of the embankment reinforced by wholesale biaxial geogrid in a road engineering as an example, the influence of the internal force and filling height of the reinforced materials in different layers on the tensile force of the reinforced materials was analyzed by Madis finite element software. The conclusions are as follows:

(1) The overall stability coefficient of the slope in the natural state is 1.369, which meets the requirements of the design specification, indicating that the proposed reinforcement scheme can meet the requirements.

(2) In the first and second grade slopes, with the increase of the number of layers of reinforced materials, the tensile force of the biaxial geogrid for sale gradually increases, and the reinforcement effect of the high quality biaxial geogrid is obvious. The variation of the tensile strength of the reinforcement is mainly concentrated on the biaxial geogrid factory price. The rear half of the grid. In the 2nd and 3rd grade slopes, the tensile force of each layer of biaxial geogrid manufacturers increases first and then decreases with the increase of the slope distance, and there is a maximum value.

(3) The stress of the reinforced material depends on the stress at the slope where it is located, and the effect of the wholesale biaxial geogrid on the reinforcement of the slope is more significant.