Application of Geocells in Soft Foundation Treatment of Highway Engineering

Abstract: This paper analyzes the application of geotechnical chamber technology in the soft roadbed treatment of highway engineering with the general situation of the project, including five profiles of plastic geocells manufacturers, quality control of the grid, pre-construction preparation, construction technology, and construction quality control standards. The analysis shows that the application of plastic geocells factory price technology in the process of processing road soft foundation can improve the bearing capacity of highway engineering and save the cost of highway engineering.

Keywords: high quality plastic geocells; weak foundation; construction technology

introduction

The plastic geocells manufacturers is a three-dimensional material for weak foundation sections and play an important role in engineering construction. It can effectively prevent the occurrence of negative subsidence and reduce the possibility of ground collapse or even collapse. When used together with the geogrid, it can effectively prevent the roadbed from breaking and reflecting cracks, prolong the service life of the road, and play an important role in ensuring the quality of road use.

1. Geocell

As a new type of three-dimensional reinforced material, the plastic geocells factory price is mainly composed of high-strength HDPE broadband, and a mesh-shaped cell structure formed by strong welding. The main feature is strong flexibility, which is convenient for transportation management and use. It can be filled with sand and other materials during use.

2. Quality control of geocell construction

2.1 Geocell quality requirements

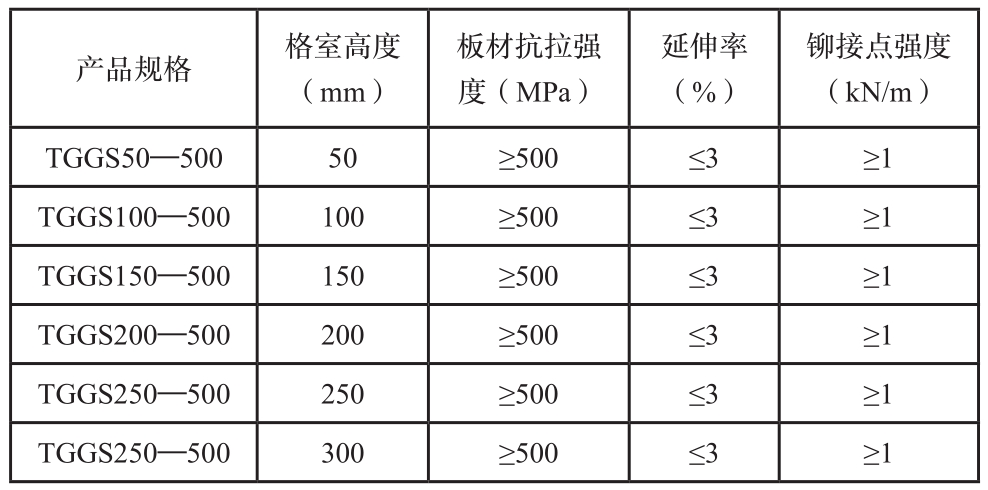

Up to now, there are many manufacturers selling plastic geocells factory price in the market, and the quality status is mixed. The performance and index parameters of each product are different. Therefore, as a project procurement personnel, it is necessary to have an overall understanding of the project. In the procurement process, there are three goods in the procurement process. In order to prevent adverse effects, road construction will be damaged. It is necessary to select the appropriate geogrid. Room to improve land carrying capacity. The performance indicators of high-strength high quality plastic geocells are shown in Table 1.

Table 1 Performance Index Table of High-Strength Geocell

2.2 Raw materials

2.2.1 Aggregate

The raw materials required for the project construction design need to be kept ventilated, clean and dry. All raw materials need to be inspected before the construction is set up. Those that do not meet the labor standards should be withdrawn in time. The choice of crushed stone needs to grasp the particle size of the stone. The crushing value needs to be set in advance, always controlled below 28%, and the needle-like content should always be controlled at 13%. For the particles, less than 0.6, the liquid limit and plasticity index should be tested in time.

2.2.2 Water

The development of the project is inseparable from a large number of water sources plastic geocells factory price. The design and construction of the project rely mainly on local river water.

2.3 grading design

In this project, the aggregate used in the construction is selected, and the detailed screening is carried out, and the calculation is carried out according to the particle composition. After the calculation, the result is obtained as the comparison value of the aggregate composition, and the graduation requirements for the composition mixture need to be satisfied. The requirements in Table 1.

At the same time, the project has been tested, the various aggregate ratios of the project are set as: particle size 10 ~ 30mm gravel: particle size 5 ~ 15mm gravel: 0 ~ 5mm gravel; and lime mass ratio is determined to be 29:33 : 38, wherein the maximum dry density is 2.26 g/cm 3 in the control of the dry density wholesale plastic geocells, and the optimum water content is 4.9% in the water content control, and the next process can be performed after the grading design is completed. Carry out.

3. Preparation before starting work

3.1 Mixing site layout

3.1.1 Site selection

It is generally necessary to comprehensively consider the specific traffic environment wholesale plastic geocells, the sanitary environment, whether the site is open and ventilated, and whether the materials are convenient to transport. The site should be chosen to be built in a flat, open, and airy environment. There are several outlets to ensure smooth drainage. Sites need to specifically consider actual functions and industry standards during site selection planning. When the materials are piled up on the site, it is necessary to classify the properties of the materials, try to avoid direct sunlight, and place them in a cool and humid place. In addition to the fixed material placement area, the site also needs parking areas and mixing areas for machinery and equipment. Each area requires a special person to carry out management supervision to ensure the cleanliness and cleanliness of the environment in the area wholesale plastic geocells, and to prevent sunshine and rain. Adverse effects caused by the environment. All mechanical equipment needs to be regularly scheduled to ensure that it can be used at any time. Each area needs to have a corresponding management logo to avoid congestion when storing materials and equipment.

3.1.2 Equipment Preparation

According to the construction task, contract period and quality requirements wholesale plastic geocells, it is equipped with mechanical equipment such as stabilized soil mixing equipment, vibratory roller, rubber roller, loader, sprinkler, dump truck, etc., and all equipment is installed and commissioned before starting to ensure the machinery. The device is in good working order.

3.2 Cushion acceptance

Adherence to work must be carried out in accordance with relevant industry regulations and specific operational methods and operational standards for construction. For road surfaces that do not meet the quality acceptance of highway engineering, technical personnel needs to immediately deal with the situation according to the situation.

4. Construction process

4.1 Construction preparation

(1) Stake out the center line and do a good job of cleaning the bottom layer.

(2) According to the industry standard requirements and the specific planning of the project progress, accurately calculate the road surface flatness of the final requirements of the rolling test.

4.2 Geocell layout

(1) Zhang Lag room, the room is always in a state of tension. The area of the chamber under tension and tension is 500cm long and 440cm wide.

(2) Perform roadbed drilling and setting. The beginning of the plastic geocells manufacturers began to break into the subgrade, using materials such as hammers and steel bars. The height of the steel pile is always kept below the cell.

(3) Hanging high quality plastic geocells.

(4) According to the specific road surface information and the results that the road engineering needs to achieve, before designing the specific width of the plastic geocells for sale, it is necessary to carry out the field measurement and development plan and determine the final aspect ratio after the precise amount.

(5) When the wholesale plastic geocells is in a relaxed state, in order to ensure the balance of the product and the complete function, it is necessary to connect the cells, and the connecting tool is the compartment connecting part of the plastic geocells for sale.

(6) Carry out the tensioning work of the plastic geocells for sale, so that each plastic geocells manufacturers can reach a fixed size and maintain the tension. After the tension is completed, the high quality plastic geocells are fixed by the steel piles.

(7) Material filling. At this time, the plastic geocells factory price is kept in a state of tension, and the building materials are filled into the cells.

4.3 Material filling

(1) Confirm the integrity of the cell before filling. In order to ensure the smooth completion of the filling work, it is necessary to confirm the integrity of the compartment. If the damage is found, it should be disposed of in a timely manner.

(2) The filling work must be completed within 48 hours after the completion of the laying work to ensure that it is carried out under the tension of the compartment.

(3) As the filling material of the cell, it is necessary to ensure that the thickness exceeds 10 cm of the cell, and the excess portion is a strong protective layer for the cell. In the filling process, the protective layer and the gravel need to be filled together wholesale plastic geocells. In order to ensure the maximum improvement of work efficiency and improve the quality of the project, the loosening factor of the filling needs to be based on the filling result. The looseness coefficient is generally between 1.3 and 1.5 to achieve the best filling state.

4.4 leveling and rolling

Compaction step: firstly carry out voltage regulation, in the process of voltage regulation, it is necessary to control the number of rolling, generally rolling about 3 times, and the compaction degree of the voltage regulation should reach 88% or more, then carry out slight vibration rolling plastic geocells for sale, After a slight vibration and rolling for 3 to 4 times, the pressure is applied. Finally, the caster compactor is used for rolling, and the caster compactor is compacted until there is no tire trace. In the process of rolling, it is necessary to control the quality of the rolling, and it is impossible to have problems such as starting waves and bulging.

4.5 Construction Precautions

(1) Geogrid tension is the most important and most important part of the whole construction. During the tensioning process, it is necessary to maintain the tension of the cell to avoid the looseness of the cell.

(2) When the second step is to fill the materials, the building materials need to meet industry specifications and design expectations.

(3) Set the necessary drainage device.

(4) Storage location needs to be considered. Stored in a location that is not easily exposed to direct sunlight to avoid deformation and deterioration.

4.6 Health and Traffic Control

After the grading of gravel is filled, it should be sprinkled and maintained. During the spraying process, the surface of the aggregate should be kept moist, and no excessive water should be sprayed to prevent local water accumulation on the road surface. As it is a reconstruction project, it is necessary to carry out construction along the side of the vehicle. Traffic control and safety work should be done during the construction of graded gravel and throughout the health period.

5. Construction quality control standards

Deflection in the construction of the road is a measure taken to detect the quality of control. Whether the three-dimensional material of the plastic geocells manufacturers can play a beneficial role in the concrete construction work, whether the quality can reach the standard after the completion of the project, Indicators are used for verification. Deflection is an indicator means for quality supervision by enterprises and employers after the completion of the project. After the completion of the project, the use of deflection as a means of quality assessment. The test section is selected in the plastic geocells for sale, and the data is compared with the old roadbed. The comparison results show that the construction of the high quality plastic geocells is steeper and the quality is better than that of the old roadbed.

6. Conclusion

The project is a road reconstruction project. As a new type of building material, the plastic geocells factory price is more expensive than ordinary flat materials, but compared with the deep modification of the pavement with lime piles and gravel piles, the geotechnical grid The cost of the room is far less than this, and because of the good use effect of the plastic geocells for sale, the high product utilization rate, the cost is lower than the traditional pavement pile foundation construction project, the project quality is guaranteed, so it is widely used in pavement construction. . The practice of this project proves that the use of high quality plastic geocells for pavement reconstruction, the actual cost savings of 60 million yuan, and the soft foundation treatment through the plastic geocells manufacturers, the effect is better, the post-maintenance costs are reduced, improve the profit rate of enterprises, increase engineering efficiency, On the basis of paying close attention to quality control, we will ensure that both social benefits and corporate benefits will be harvested.