Application of Geogrid in Highway Subgrade Reconstruction Project

Abstract: Since the reform and opening-up, China’s national economy has developed rapidly, which has led to a gradual increase in traffic volume. A large number of established highways have been unable to meet the current traffic development needs, and the reconstruction of subgrade projects has become a major problem to be solved. The application of wholesale fiberglass geogrid reinforcement technology in the roadbed widening and rebuilding project can not only solve the problem of differential settlement of roadbed but also further expand the internal friction angle of the roadbed soil, which is of great significance to the improvement of roadbed bearing capacity. On the basis of fully understanding the characteristics of fiberglass geogrid for sale reinforcement technology, combined with specific engineering cases, the construction parameters are determined through the establishment of finite element model to further standardize the construction process and improve the overall quality of the project.

Keywords: wholesale fiberglass geogrid; roadbed reconstruction; engineering overview; construction parameters

introduction

In recent years, along with the rapid development of the social economy, China’s road construction industry has also developed by leaps and bounds. While the economy is driving the development of the transportation industry, the amount of road traffic that has been built in China has gradually become saturated. How to do a good job of road widening and transformation is particularly important. In the roadbed reconstruction project fiberglass geogrid factory price, the phenomenon of differential settlement of new and old roadbeds often occurs. The long-term existence of such problems will further aggravate road surface diseases, leading to problems such as cracking and deformation fiberglass geogrid factory price. To this end, it is necessary to combine the local conditions and the rational and rational roadbed structure on the premise of economic principles to enhance the horizontal connection between the old and new roadbeds and improve the integrity of the new and old roadbed. The application of fiberglass geogrid for sale in the roadbed reconstruction project can not only effectively improve the new roadbed stiffness but also reduce the settlement. At the same time, it can further strengthen the structural relationship between the widened part and the original roadbed by relying on the tensile strength of the geosynthetic material. Form a whole, effectively improve the performance of the project and promote the sustainable and healthy development of the road construction industry.

1. Geogrid reinforcement technology features

As a common geosynthetic material, high quality fiberglass geogrid has advantages in terms of performance and application effects compared to other materials. The plastic wholesale fiberglass geogrid can be formed into a polymer mesh by stretching, and its shape includes a square shape, a rectangular shape, and the like. According to the specific direction of the manufacturing stretch, it can be divided into two types, that is, one-way or two-way stretching. After the polymer sheet is pressed, it is punched thereon, and on the basis of heating, a directional stretching operation is performed. In the application of high quality fiberglass geogrid reinforcement technology, it can promote a certain frictional force between the fiberglass geogrid manufacturers and the soil, and can also form a large passive resistance performance, which is a good constraint on the lateral deformation of the soil of the new and old subgrade joints. effect. In addition, the high quality fiberglass geogrid-reinforced mesh can also be used to enhance the interaction between the upper and lower layers of the fiberglass geogrid for sale grid, stabilize the soil, and improve the bending strength and shear resistance of the soil.

2. Project Overview

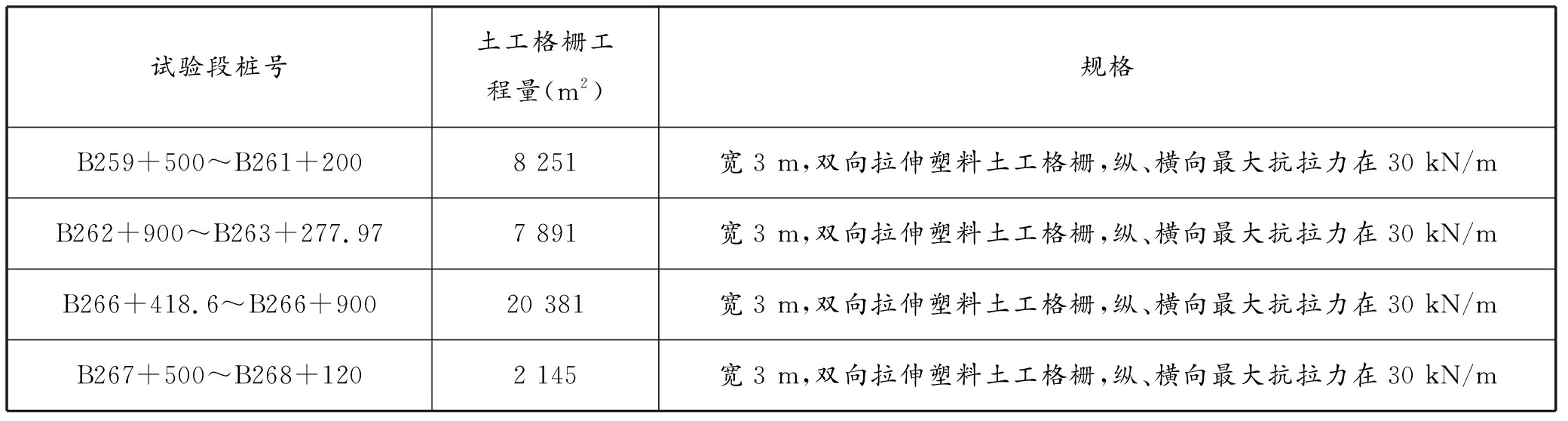

After a road project has been completed and opened to traffic, it has been in operation for about 8 years. With the continuous increase in traffic volume, the service level has become saturated, and it is urgent to enhance road capacity fiberglass geogrid factory price. Therefore, it is decided to implement the road subgrade reconstruction. The total length of the road reconstruction project is 162.1km, and 12m is the original road pavement width. During the reconstruction, it is decided to lay three layers of wholesale fiberglass geogrid on the longitudinal excavation and filling of the roadbed. After the reconstruction, the pavement width will be increased to 18m, and the two sides will be widened. construction. According to the geological survey, the middle-grade mudstone is the base of the road section, while the consolidated clay is located at the old roadbed. The test section parameters are shown in Table 1.

Table 1 test section parameters

3. Finite element analysis

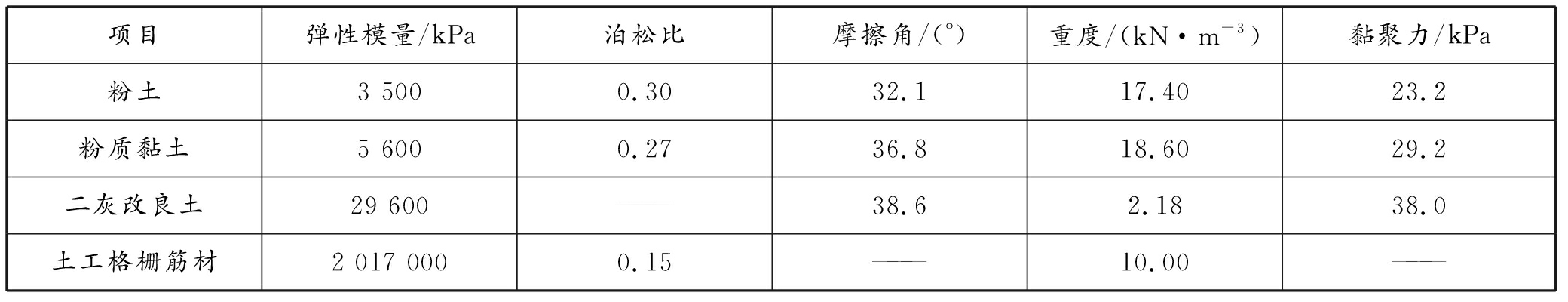

In order to obtain the fiberglass geogrid for sale reinforced construction parameters, the finite element model can be established. In the roadbed reconstruction project, according to the strength reduction method, 1.57 is obtained as the roadbed stability coefficient, which is consistent with the roadbed stability regulations. For this reason, its stability is not considered in the finite element analysis. On the basis of the finite element analysis program, a numerical model can be established to analyze the relevant construction parameters, as shown in Table 2. The two-ash improved soil can be selected as the filling for the roadbed reconstruction and widening section, and the reinforced materials, such as wholesale fiberglass geogrid, can be laid.

Table 2 calculates the value

In terms of grid reinforcement effect, the length of the grid reinforcement and the spacing of the reinforcement are the main influencing factors. According to the analysis, 0.4~0.8m is the range of grid reinforcement spacing, and 4m is the optimum value of grid reinforcement length. As a flexible reinforced material, the application of fiberglass geogrid for sale in the roadbed reconstruction project can comprehensively improve the mechanical performance of the widened roadbed.

4. Construction technology of geogrid in highway subgrade reconstruction project

4.1 Construction preparation

Before the construction, according to the specific conditions of the construction site, the construction plan is reasonably determined, and according to the plan fiberglass geogrid factory price, it is extremely important to do all the construction preparation work, which is also an important prerequisite for improving the construction quality.

(1) Measurement stakeout. Before construction, relevant personnel should be organized to understand and master the design requirements and drawings, and strictly follow the construction specifications, and do a good job in the investigation of the construction site. After the completion of the technical delivery, it is necessary to timely use the roadside piles and embankment slopes. The feet are released. The wholesale fiberglass geogrid laying position is released by the total station instrument, and the cross-section elevation review of the refurbished and widened section is completed to ensure that the design requirements are met.

(2) Clean up the site. For the original road surface, the surface cleaning work should be done. After the surface debris is thoroughly cleaned, if there are concave or protruding parts, the site should be leveled in time to ensure a good flatness of the construction site. fiberglass geogrid for sale construction can only be carried out after the above construction work is completed.

4.2 Geogrid laying

According to the actual situation of the construction site, fiberglass geogrid manufacturers-reinforced mesh with 30mm×40mm size can be used. The rectangle is the cross-section shape of high quality fiberglass geogrid reinforced ribs. The high quality fiberglass geogrid can be laid by manual construction. And to ensure that it is consistent with the construction technical indicators. It is required to lay a layer of plastic fiberglass geogrid manufacturers at a distance of 0.6m to the bottom of the slope-bed surface of the existing cable-wide section, without the need to be in the middle of the gravel cushion; if the height of the new single-line foundation is more than 4m, it should be 1.2m spacing laying. In addition, according to the widened lateral design length of the subgrade, the reinforced fiberglass geogrid manufacturers should be laid on the inner side of the subgrade step – the roadbed widens the slope direction, and the fiberglass geogrid manufacturers laying length is sufficient, and it is strictly prohibited during the fiberglass geogrid factory price laying process. Overlap and distortion.

4.3 Bottom geogrid laying

The application of the fiberglass geogrid factory price reinforcement optimization technology requires a reasonable laying position, and the wholesale fiberglass geogrid laying range can be accurately marked by wooden piles and the like. Generally, the high quality fiberglass geogrid laying is carried out under the condition that the flatness of the lower bearing layer is good along the longitudinal direction of the roadbed. When laying the fiberglass geogrid manufacturers on the underlying roadbed, the grille must be straight and free of distortion. During the construction process, the bottom fiberglass geogrid factory price can be connected by the seaming method. According to the actual situation of the project, the two adjacent fiberglass geogrid manufacturers connections can be spliced by high-strength polypropylene tape or connected by lap joint. The connection width needs to be controlled above 20m. U-nail construction can be selected when the grille is fixed to avoid affecting the quality of the fiberglass geogrid for sale. After the fiberglass geogrid manufacturers are laid, the earthwork should be filled in order from the two sides to the middle. It is required to discharge directly on the soil surface, but the discharge height must be reasonably controlled, generally below 1 m. At the same time, it is necessary to control the earthwork filling thickness within 35 cm. After the above construction is completed, the rolling construction can be carried out. The optional equipment includes bulldozers, road rollers, etc. It is required to properly control the degree of compaction according to the design regulations.

4.4 Upper geogrid laying

After the bottom high quality fiberglass geogrid laying operation is completed, the compaction degree meets the design requirements, and the upper wholesale fiberglass geogrid can be laid. The laying process of this layer is basically equivalent to the laying of the underlying high quality fiberglass geogrid. The difference is that the fiberglass geogrid for sale width should be the same as the top width of the fill layer. After the fiberglass geogrid manufacturers are laid, it is also necessary to do the roller compaction construction to ensure that the quality of the roller compaction construction meets the relevant specifications. Generally, when rolling, the construction will be carried out in the order from the two sides to the middle. After the compaction degree meets the design requirements, the construction can be stopped.

4.5 Construction Maintenance

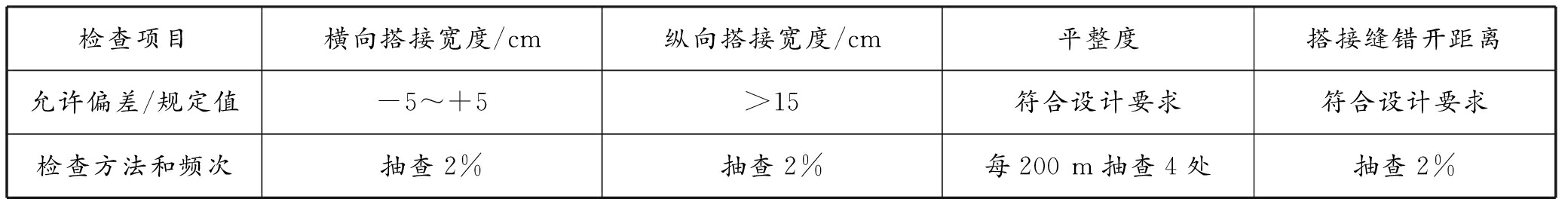

After the completion of the overall construction, the construction quality of the widened roadbed should be tested in time. The inspection standards are shown in Table 3.

Table 3 inspection standards

After the quality of the inspection is qualified, the upper layer of the filling can be paved by manual means. The roadbed filling construction generally needs to be completed within 2 days, followed by rolling construction. When curing construction, the exposure time should be reduced. Usually, the curing period is set at 28 days. After the maintenance is completed fiberglass geogrid factory price, the traffic can be opened. After the construction of the high quality fiberglass geogrid is completed, it is strictly forbidden to grind the construction machinery or the vehicle. During the construction process, the quality of the wholesale fiberglass geogrid should be inspected in detail to avoid damage, such as puncture, tearing, etc. If the situation is more serious, the materials should be replaced in time.

5. Conclusion

In order to meet the increasing traffic demand, a large number of highway projects in China must be rebuilt and improved to improve road capacity. The rational application of fiberglass geogrid for sale in the reconstruction of highway subgrade can effectively enhance the stability of the subgrade and improve the bearing capacity of the subgrade fiberglass geogrid factory price. This is of great significance for improving the quality of highway construction.