Construction Process and Rewinding Reasons of Plastic Drainage Board and Treatment Countermeasures

Abstract: In the construction of engineering, soft soil foundation is often encountered. The soft soil foundation has the characteristics of low bearing capacity, low permeability, high compressibility and high water content, which directly leads to the settlement of soft soil foundation, which affects the quality of the project. Therefore, strengthening soft soil foundation treatment has become the focus. In soft foundation treatment, plastic dimple drainage board for sale is the most common treatment method. However, in actual engineering, the phenomenon of reintroduction often occurs. The article discusses the construction process of the plastic dimple drainage board manufacturers, discusses the reasons and measures of its retraction, so as to give full play to the utility of plastic wholesale storage and drainage sheet.

Keywords: soft soil foundation; plastic dimple drainage board manufacturers; construction technology; reasons for returning; countermeasure

Plastic wholesale storage and drainage sheet is mainly used in soft soil foundation treatment. The application of drainage consolidation method and the level of construction technology directly affect the time of drainage consolidation and affect the overall quality of the project. For this, the construction personnel should fully grasp Skilled application of plastic dimple drainage board for sale construction process 1. In the construction of the 220kV Xiyue Substation Santong Yiping and grounding grid project, the soft soil foundation treatment needs to use plastic drainage board. The article focuses on the soft soil foundation engineering of the project and discusses the application of plastic dimple drainage board manufacturers.

1. Project Overview

In the construction of the 220kV Xiyue Substation Santong Yiping and grounding grid project, the soft foundation treatment is the site leveling work of the project. The main contents of the work are: First, the site is excavated with 0.5m thick topsoil, excavated pond foundation, filled Appropriate amount of fine sand, for the first leveling, so that the city to the elevation of 1.05m; second, backfilling the coarse sand drainage layer 1.2m, preloading treatment, it is estimated that 1.2m settlement will be generated, for this, in the coarse sand drainage layer Filled with 4.85m of fine sand layer and 6.05m of sand in the station area. Thirdly, insert plastic dimple drainage board for sale. When the soil layer is filled with more than 85% consolidation rate and 1.2m settlement, the site is leveled. carry out. The soft soil treatment area is about 19,557 m2.

2. Plastic drainage board construction process

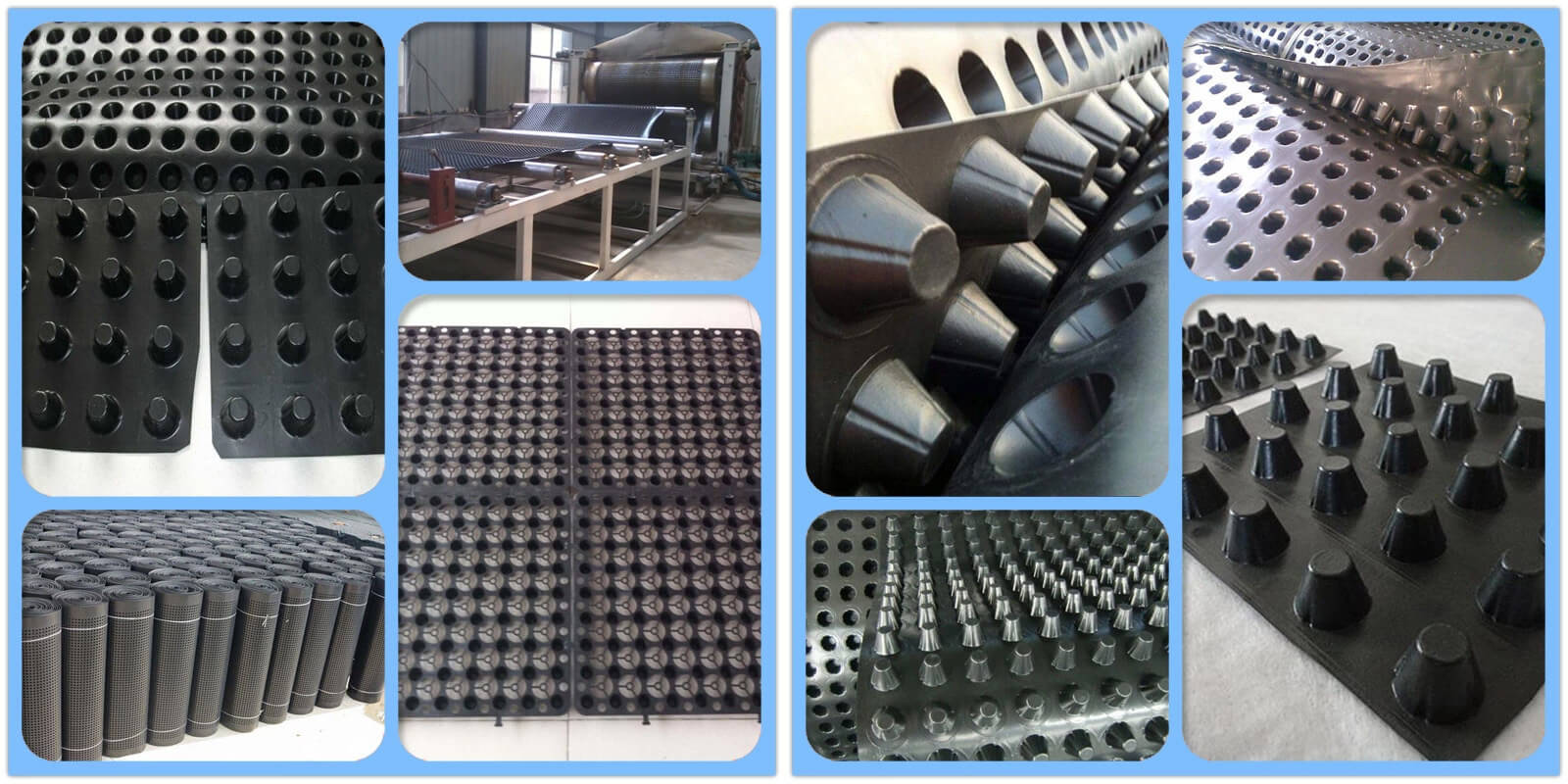

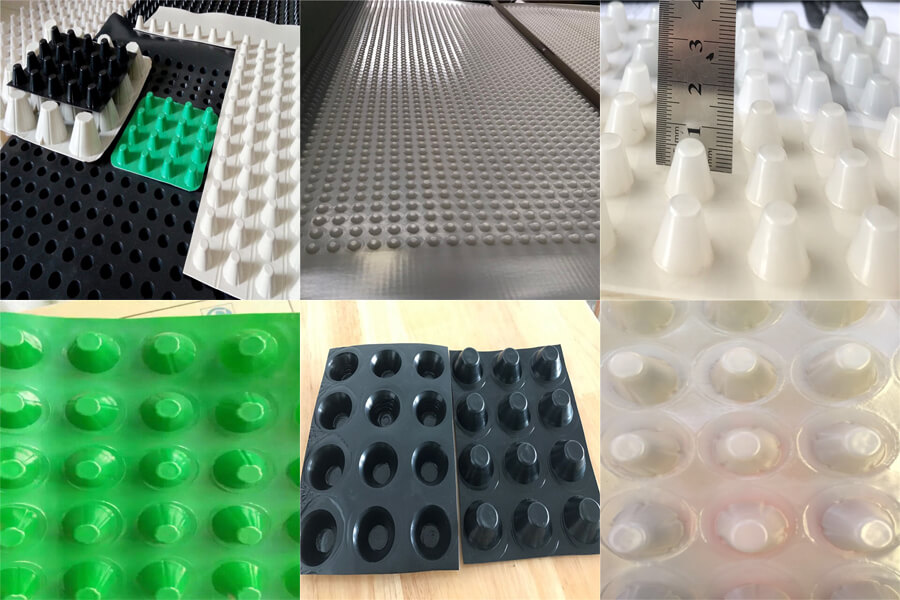

2.1 Simple overview and advantages and disadvantages of the plastic drainage board

In soft soil foundation treatment, the application of plastic dimple drainage board manufacturers construction technology is mainly to use the principle of drainage consolidation, using plastic dimple drainage board for sale to discharge the water in the foundation by capillary action, to improve the stress between the soil layers and make the foundation Consolidation and settlement to a certain extent, effectively improve the strength of the foundation and ensure the overall quality of the project.

In soft soil foundation treatment, the use of plastic drainage board has the following advantages: the dimple drainage board for sale can be mass-produced, the quality of the wholesale storage and drainage sheet is easy to control, and the cost is low; the section of the dimple drainage board manufacturers is small, generally only 10cm wide, which has a greater impact on the foundation. Small, can better guarantee the quality of the foundation; when the construction process is applied, the construction machinery is lighter and the bearing capacity of the foundation is not high. Of course, this kind of construction process also has certain defects. When the foundation is strengthened, the settlement is large. Therefore, when the process is applied, the relevant personnel should calculate the settlement height in detail, and lay a certain thickness of soil layer in advance according to the settlement amount to ensure the construction area. Flatness.

2.2 Construction process of the plastic drainage board

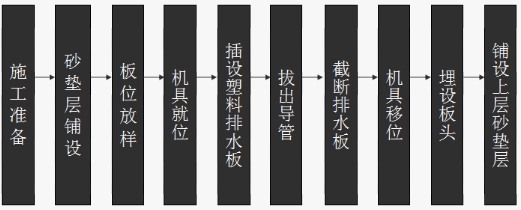

2.2.1 The overall process of the process is shown in Figure 1.

Figure 1 Plastic drainage board process flow chart

2.2.2 Preparation for construction

In the early stage of construction, first of all, relevant personnel should clean up the construction site in detail. As long as obstacles such as trees and debris are located in the construction scope, they should all be cleaned up. If there is accumulated water, it should be eliminated in time. Secondly, equipment and construction materials will enter the site, and the equipment will be inspected in detail to ensure the quality of the machinery and equipment, whether the materials meet the construction requirements, and prevent inferior materials from entering the construction site to ensure the construction quality. Finally, the construction personnel is in place, according to the level of capacity of the construction personnel, each work is allocated and implemented reasonably, and reward and punishment measures are formulated to ensure the overall quality of the project.

2.2.3 Sand cushion laying

In this soft soil foundation construction, the thickness of the sand cushion is 30cm. Firstly, 15cm sand cushion is laid in the construction area. The drainage capacity is used to improve the bearing capacity of the soft foundation, and the 15cm sand cushion is laid again. The fixing method makes the sand cushion layer compactness meet the requirement, that is, the consolidation ratio reaches 90% or more. After the sand cushion is laid and the drainage is consolidated, the surface should be even and flat to avoid the inclusion of impurities in the sand layer.

2.2.4 Stakeout of the board

Relevant personnel uses the overall design drawings of the project, reasonably pile the pile, and mark the station number. Also, the support axis should be perpendicular to the centerline and the curve should be consistent with the normal direction. When lofting, draw a detailed layout diagram to ensure the accuracy of the construction staff stakeout. Pay attention to the triangular strip layout to avoid missing cloth or super cloth. In addition, after the first layer of sand cushion is laid, the construction personnel should lay the board on the sand cushion according to the layout diagram, and the standard is detailed.

2.2.5 Inserting plastic drainage board

In the preparation work in the early stage of construction, the mechanical equipment has been inspected in detail and in place, and the dimple drainage board manufacturers have also passed the quality inspection and placed in the proper position. In this regard, first, the constructor should load the dimple drainage board for sale into the reel, use the frame with the pulley to introduce the roll-shaped wholesale storage and drainage sheet into the casing, and insert the pipe into it. According to the pre-designed insertion depth, the pipe is clearly drawn. The scale is prepared for the later stage; secondly, through the end of the pipe, the wholesale storage and drainage sheet is led out, folded back, and the short steel bar is clamped, and the ordering machine is used to order. Again, the drain plate is tightened, the catheter is adjusted, aligned with the plate, and vibrated while pressing the catheter into the foundation. After that, when the catheter reaches the marked position, the catheter is pulled out, and the drain plate is anchored to the bottom of the hole by the short steel bar due to the soil being squeezed. Finally, at a position 50 cm above the sand cushion, the dimple drainage board manufacturers are cut, the equipment is displaced, the head is buried in the sand cushion, and the sand layer is laid. After completion, the next step can be performed.

3. Reasons for the return of plastic drainage board construction

In the construction of plastic dimple drainage board for sale, once the recirculation problem occurs, it will directly affect the soft soil foundation treatment results, affecting the overall quality of the project, and the economic and social benefits will also be affected. In this regard, in the construction of the project, the relevant personnel should know in detail the reasons for the return of the plastic wholesale storage and drainage sheet, and propose solutions to the problem, so as to reduce the phenomenon of the belt return, ensure the treatment effect of the soft soil foundation, and improve the overall quality and efficiency of the project. . Here are a few common reasons for the return.

3.1 Silt into the catheter

Some foundation soils are silt soils, which have poor stratification, high fluidity, and high viscosity. Plastic dimple drainage board for sale are inserted. Due to the characteristics of silt soil, it is easy to enter the tube from the gap between the casing and pile shoes. The air between the tube and the cylindrical wholesale storage and drainage sheet is blocked. When the casing is pulled out, the dimple drainage board manufacturers adhere to the inner wall of the casing due to the sludge, and is pulled out together with the casing, and is not anchored at the bottom of the hole as expected. The big back belt has affected the quality of the project.

3.2 Insufficient worker level

In the construction of plastic wholesale storage and drainage sheet, the operation level of the workers directly affects the quality of the construction. If the construction personnel lacks proficiency in the operation and the specialization is not good, it will easily lead to the phenomenon of returning. For example, when the plastic dimple drainage board for sale is lapped, if the construction level of the staff is insufficient, the lap joint between the drainage plates is not strict. When the pipe is pulled out, it is easy to cause the sludge to enter the gap, or the anchor shoe falls off, resulting in a large Rewind phenomenon. In addition, in the process of inserting the insertion rod of the plastic dimple drainage board manufacturers into the foundation, the insertion rod is inclined due to the staff, and the verticality of the hole position deviates, which easily causes the cylindrical plastic wholesale storage and drainage sheet to closely adhere to the duct wall, and between the wholesale storage and drainage sheet and the duct wall. The frictional force increases, which in turn causes a backlash phenomenon.

3.3 Soil water content is large

In the treatment of soft soil foundation, some soft soil bases contain large water. During the process of inserting plastic dimple drainage board manufacturers, the soil has more moisture content, and the resistance to the wholesale storage and drainage sheet is less, making the wholesale storage and drainage sheet and soil The frictional force of the body is smaller than the pulling force when the casing is pulled up, which leads to the phenomenon of returning belt, which affects the construction process of the plastic dimple drainage board for sale and is difficult to reach a certain level.

3.4 The soil layer is dry and hard, and the drainage board is shallowly shallow.

When the plastic dimple drainage board manufacturers are inserted, if the soil is relatively hard, it will easily lead to the shallow depth of the dimple drainage board for sale. When the pipeline is pulled out, the soil at the bottom of the hole cannot be restored to its original state because it is dry and hard, and the soil will directly The pipe is clamped to the plastic wholesale storage and drainage sheet. If the brute force is used, the returning phenomenon is more obvious. Until the casing rises to the soft plastic soil layer, the soil can clamp the bottom end of the wholesale storage and drainage sheet, and the returning phenomenon will disappear.

4. the return processing countermeasures

4.1 sludge return treatment

In the application of the drainage consolidation method, if there is a silt layer in the foundation soil, in order to avoid the sludge entering the gap of the conduit, the belt is returned, which affects the effect of drainage consolidation. Before pulling out the catheter, the relevant personnel can flush the water into the conduit. On the one hand, the sludge in the conduit is cleaned, and the friction between the plastic dimple drainage board for sale and the conduit is reduced. On the one hand, the water pressure will be on the plastic dimple drainage board manufacturers and the wall of the conduit. The mud is pressed down to solve the problem of returning.

4.2 Improve the professional level and operational ability of construction workers

Before the overall construction of the project, the company should start to improve the capacity of the construction personnel. Training before construction, improve the professional level of construction workers and implement a one-to-one mechanism. The experienced staff will lead the inexperienced staff, which guarantees the quality of plastic dimple drainage board for sale construction, avoids the phenomenon of returning belts, and can effectively exercise construction. The level of personnel operation will improve the competitiveness of enterprise talents and promote the development of construction enterprises.

4.3 Controlling different soil qualities

In the construction of plastic dimple drainage board for sale, if the foundation soil is soft plastic soft clay, the construction personnel can choose to fold back when the plastic dimple drainage board manufacturers are folded back. If this method cannot avoid the belt retraction phenomenon, the relevant personnel can increase the empty space according to the actual situation of the project. The tube is oscillating, or a high-pressure water gun is installed, which avoids the return of soft clay by vibration or impact. In the construction of plastic soft clay, in order to avoid the problem of rewinding, the construction workers can use the waste steel bar to transform the pile boots, cut the scrap steel into 15-20cm long steel bars, fold the steel bars back into the casing, and pull the drainage plates closer. When the steel bar is closely attached to the groove of the casing head, the drainage plate can be set to increase the friction between the pile shoe and the drainage plate, the pole shoe, and the soil body, and reduce the belt return phenomenon. In addition, because the wholesale storage and drainage sheet is in direct contact with the soil if the soil is hard, it is not suitable to use this method.

Summary

In summary, the article discusses the site leveling of the 220kV Xiyue substation three-way and one-level grounding and grounding network construction, briefly describes the construction process of soft foundation treatment, and discusses common reincarnation phenomena, such as: sludge entering the pipeline, The worker’s operation level is insufficient, the soil layer is hard and the water content is high, which affects the construction quality of the plastic dimple drainage board for sale. In this regard, it is necessary to strengthen the treatment of sludge, improve the professional level of construction workers, and effectively control the phenomenon of returning belt according to soil quality, give full play to the construction effect of the plastic dimple drainage board manufacturers, and lay the foundation for the overall quality of the project.