Construction Scheme of Composite Geomembrane in Channel Anti-seepage River Treatment – Ⅰ

Loss of water leakage in canals or rivers not only reduces water use coefficients, wastes valuable water resources, but also causes groundwater levels to rise, causing damage to farmland. Only by adopting effective anti-seepage engineering measures can the leakage of canals be reduced.

Geomembrane used in canal anti-seepage project has the following advantages:

1. Good anti-seepage performance. The practice has proved that the membrane material anti-seepage channel can generally reduce the leakage loss by 90 to 95%.

2. Lightweight, less usage and less transportation.

3. Strong ability to adapt to deformation.

4. Simple construction and a short construction period.

5. Strong corrosion resistance.

6. Low cost.

The disadvantages are easy aging and short service life. The geomembrane used in the channel anti-seepage project should choose the appropriate type and specifications according to the water level, geological conditions, and project scale, and determine different construction technology solutions.

Choice of materials

The film material should be selected according to the following principles:

1. For general small and medium-sized channels, a dark plastic film with a thickness of 0.18 to 0.22mm should be selected. In cold areas, polyethylene film can be preferred; in areas with penetrating vegetation such as reeds, polyvinyl chloride film can be preferred.

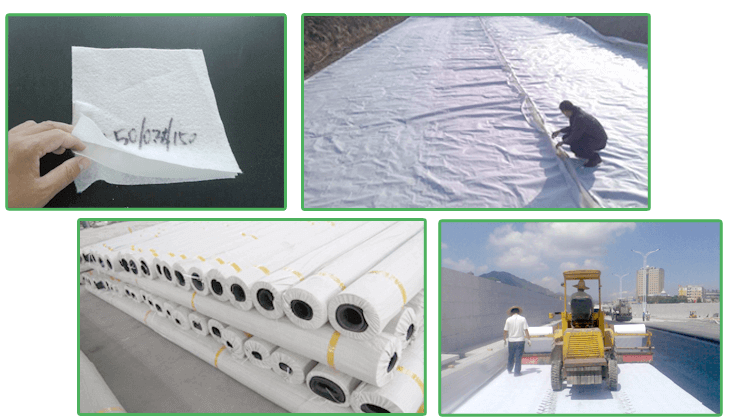

2. For impervious projects with poor geological and hydrogeological conditions, high soil frost heave or high standards, a composite geomembrane (1 cloth 1 film, 2 cloth 1 film) should be used. The comprehensive function of plane water conductivity, high strength, good resistance to wear and tear, anti-aging and other properties, no transition layer is required.

Basic structure and requirements

According to the engineering situation, single-layer impervious structure, double-layer impervious structure or composite impervious structure can be selected. The anti-seepage structure includes an upper cushion layer, a lower cushion layer, a protective layer above the upper cushion layer, a support layer below the lower cushion layer, and a drainage layer.

1. Support layer; choose according to the engineering category, natural foundation conditions and the characteristics of the geomembrane used. Generally, good sand with a thickness of 50 to 150 mm is used. It can also be covered with 1 layer of geosynthetic material or laying 1 layer of geosynthetic material on the sandy soil layer.

2. Underlayment layer: Rolled and compacted fine soil layer, fine sand layer, concrete layer, geotextile, geonet, etc. with a thickness of more than 100mm. When the soil of the base layer is a uniform and fine-grained soil body or a composite geomembrane is used, an underlying layer may not be provided.

3. Drainage layer; when the groundwater level is high and there is internal water pressure, a drainage layer or drainage and exhaust facilities should be laid between the support layer and the geomembrane. Such as water stop valve, drainage pipe, vertical and horizontal drainage ditch, etc.

4. Top cushion; foam plastic sheet, geotextile, sand gravel, sandless concrete, asphalt concrete, geonet, etc. When the protective layer is a compacted fine-grained soil of sufficient thickness or a composite geomembrane is used, a cushion layer may not be provided.

5. Protective layer. It can be selected according to the type of anti-seepage geomembrane and overburden, and the slope of the channel, and meet the frost resistance requirements. Compacted plain soil, gravel, precast or cast-in-place concrete slabs, mortar blocks or dry blocks can be used.