Construction Technology of Composite Geomembrane for Sand Blocking Dam

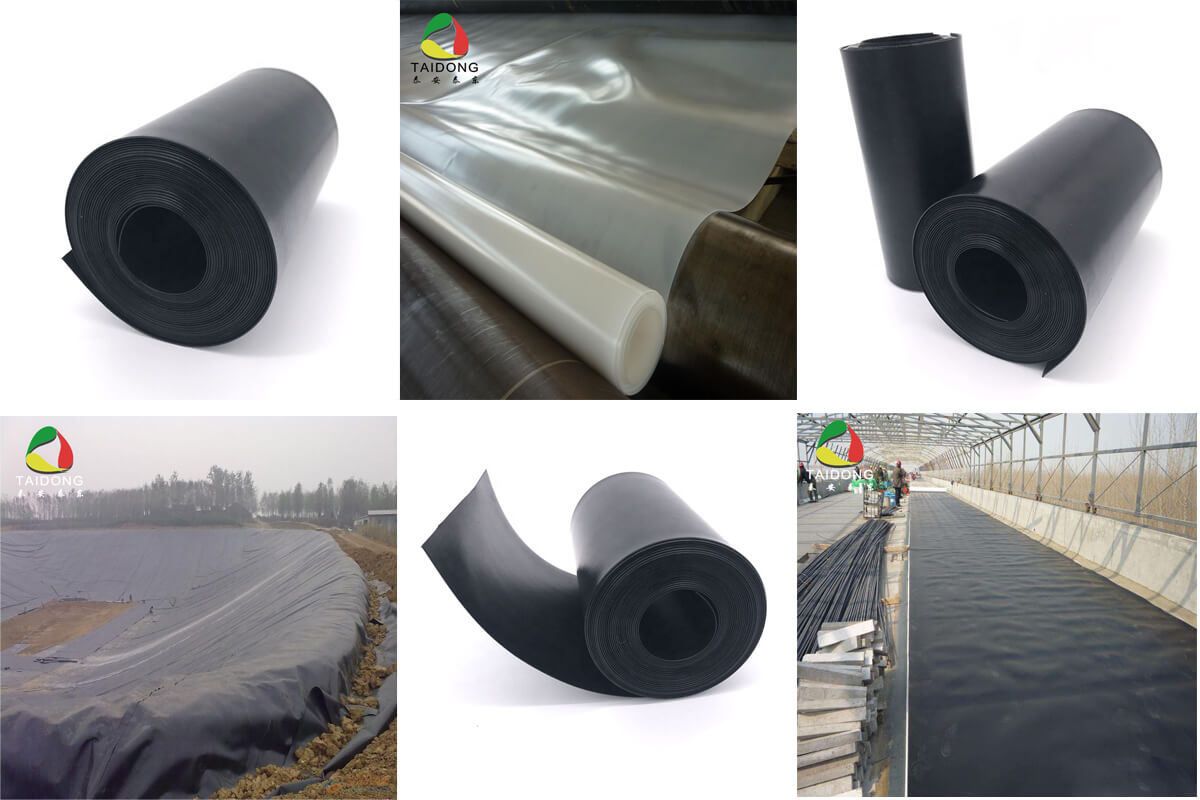

Abstract: During the construction process of composite HDPE geomembrane for sale for the dam body of the lower reservoir project of Fengning Pumped Storage Power Station in Hebei Province, the technical test results were obtained through a field test. According to the results of the process test, it is used to guide the on-site construction. The construction quality of the composite China HDPE liner factory price of the dam meets the specifications and design requirements, ensuring the anti-seepage quality of the dam body of the sand-blocking dam, and provides a reference for other similar projects.

Keywords: composite low price China HDPE liner; design requirements; a construction method

1. Project Overview

The dam axis of the dam for the lower reservoir project of Hebei Fengning Pumped Storage Power Station is located at a distance of about 1.65km from the upstream of the inlet and outlet of the lower reservoir. The dam type is a composite HDPE geomembrane for sale anti-seepage core earth-rock dam with a dam crest elevation of 1066m. The dam height is 23.5m, the dam crest length is 548m, the dam crest width is 8m, and the upstream and downstream dam slopes are 1:2.2. The dam body filling division is divided into the following steps: large stone slope protection, rockfill material, transition material, fine sand protective layer, composite high quality HDPE geomembrane, fine sand protective layer, transition material, rockfill material, and large stone slope protection.

The dam body anti-seepage is made of PE composite wholesale HDPE Liner made in China anti-seepage, the bottom of the composite HDPE geomembrane manufacturers and the surrounding concrete anchoring connection with the dam foundation and the top is anchored to the sand bar dam wall. Each side of the composite low price China HDPE liner is protected by fine sand as a protective layer, with a width of 2.5 m, and the outer side of the fine sand is connected with the transition material.

2. Main design requirements

2.1 Composite geomembrane design requirements

According to the design drawings, the main requirements for the composite China HDPE liner manufacturers of the sand barrier are as follows:

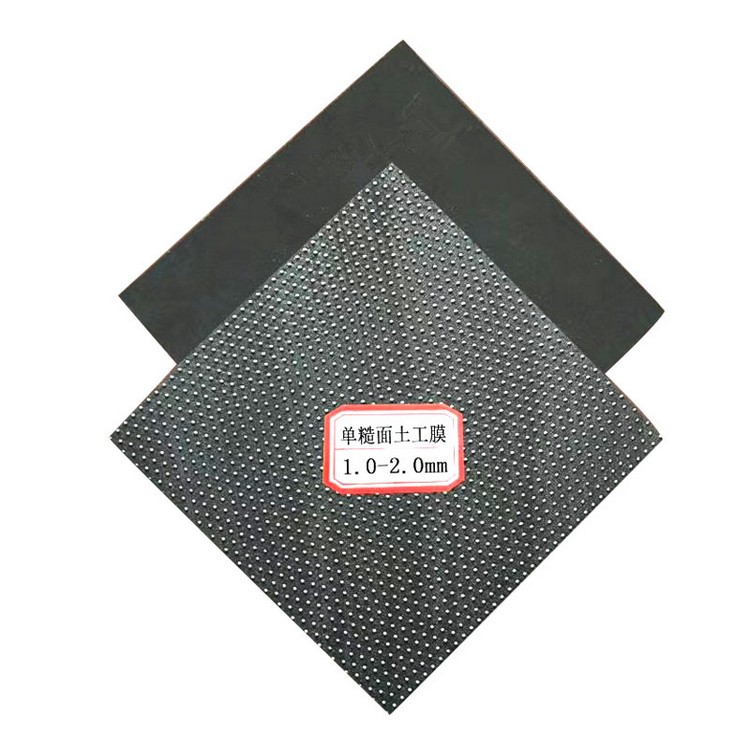

The composite China HDPE liner factory price main film has no cracks, pinholes, the main film, and the non-woven fabric have good adhesion, no detachment or wrinkling, and the physical properties should satisfy the “geosynthetic geotextile film” (GB/T17643-2011) and geotechnical The requirements of the contract material non-woven composite wholesale HDPE Liner made in China (GB/T17642-2008), the construction, lap joint, inspection and acceptance of the composite HDPE geomembrane for sale should meet the requirements of the construction technology of the dam body of the sand barrier dam and the hydropower Engineering low price China HDPE liner Seepage Control Technical Specification (NB/T35027-2014)

2.2 Composite geomembrane construction requirements

The composite wholesale HDPE Liner made in China should be carried out at a temperature above 5 °C, and the wind is less than 5 grades without rain, snow, and dust. In the special environment construction, the process test should be carried out and effective protective measures should be taken. When welding is used, the joint welding strength should be not less than 85% of the strength of the base metal. The fine sand protected on both sides of the composite HDPE geomembrane manufacturers should be made of well-graded artificial sand, the fineness modulus is 2.4-2.8, and the dry surface moisture content of the saturated surface should not exceed 6%.

The composite wholesale HDPE Liner made in China connection is made by hot-melt welding and seaming, the lower and upper layers of the nonwoven fabric are stitched, and the middle layer film is hot-melt welded. The non-woven fabric was hand-sealed with a non-woven machine and double-threaded with a nylon thread. The overlap width was 10 cm. The composite high quality HDPE geomembrane film is connected with the film by double-slot hot-melt welding, and the welding tool adopts double-slot hot-melt welding machine; if the local welding is not possible, the hole or the defect is repaired by the hot air welding torch.

3. Main construction methods

3.1 Construction preparation

3.1.1 Raw materials

The composite HDPE geomembrane for sale entering the construction site shall be inspected for appearance inspection and re-examination of physical and mechanical indexes. Pinholes, defects and uneven thickness shall not be allowed on the appearance. Geotextiles are not allowed to have cracks, holes, cracks or deterioration and deterioration. The test results must meet the design specifications.

After the composite China HDPE liner manufacturers enter the field, it will be concentrated in the spillway steel bar processing plant. The stacking part should be selected on the dry concrete floor, and the bottom part should be framed by the square wood to prevent the bottom from being damaged by the hard objects on the ground or the stones. The upper part is covered with three anti-canvas to prevent oxidation. The connection material with the concrete base is purchased according to the number and specifications of the design drawings, and the material qualification certificate is submitted to the supervision engineer for review and use.

3.1.2 Personnel training

Before the construction of the composite HDPE geomembrane manufacturers, the management personnel involved in the construction must be informed, so that the design technical requirements, construction methods, test methods, construction quality, and safety precautions should be clearly defined, and the operators should be trained in skills to master the equipment performance. , use methods, operational essentials, clear quality and safety requirements, construction considerations, etc.

3.1.3 Process test

Before the formal construction of the composite HDPE geomembrane for sale, the process test is carried out, and the construction parameters are submitted to the supervision engineer according to the process test results. After the approval and approval, the construction is carried out according to the approved construction parameters.

3.2 Composite geomembrane transportation

The on-site construction uses a loader to transport the composite China HDPE liner manufacturers coil to the paving site. When transporting composite high quality HDPE geomembrane, it should be manually loaded and unloaded. It is forbidden to directly discharge with loader. The composite low price China HDPE liner at the construction site should be placed along the fine sand strip, and it is forbidden to be placed on the transition material.

3.3 composite geomembrane paving

3.3.1 Before the composite China HDPE liner factory price is paved, the paving map shall be drawn according to the length of the axis and the length of the coil, and the weld bead and number shall be marked. The composite wholesale HDPE Liner made in China paving is carried out in the order of welding, and a piece of welding is spread. The composite China HDPE liner manufacturers laying construction should be paved along the axis of the dam. The length of each roll is 50m. The paving must be carried out manually. The composite purchase high quality HDPE liner should be unfolded from the left bank to the right bank or from the right bank to the left bank in the direction of the dam axis, and then manually. Roll the composite HDPE geomembrane for sale in the width direction, place it and take the weight fixing measures (using sandbags).

3.3.2 When paving the composite wholesale HDPE Liner made in China, the joint between the two composite low price China HDPE liner and the joint of the upper composite purchase high quality HDPE liner shall be staggered to form a “T” joint, which shall not be a “ten” shaped joint. Appropriate relaxation should be carried out when laying composite purchase high quality HDPE liner, and avoiding artificial hard folds and damage. The interface of the two rolls of composite wholesale HDPE Liner made in China must overlap at least 10 cm. At the corners where the composite HDPE geomembrane manufacturers are connected to the base, proper cutting should be taken to insure that it is properly connected to the periphery and parallel to the edge of the upper film.

3.3.3 During the filming process, the appearance of the film should be inspected at any time for defects such as breakage, pitting, and perforation. It is found that defects or damages such as perforations on the film surface should be repaired with fresh base metal in time, and each side of the patch should be 10-20 cm beyond the damaged part.

3.3.4 Detail enhancement treatment: The yin and yang angles at the corner of the base should be strengthened. The angle of the corner is cut at the bottom, and the composite high quality HDPE geomembrane with a radius of not less than 0.5m is lap welded; the bottom of the corner will be cut open. The two parts are welded together and then reinforced with another composite China HDPE liner factory price with a radius of not less than 0.5 m.

3.4 Welding of composite geomembrane

3.4.1 Welding equipment

The composite China HDPE liner manufacturers horizontal joint and vertical joint are double-slot hot-melt welding. The welding machine adopts the Leicester 800 HDPE geomembrane for sale welding machine provided by the manufacturer. The machine adopts the hot wedge structure, and the temperature control part adopts automatic constant temperature PID control. The control precision High, temperature fluctuations are small. The speed control part adopts pulse width modulation (PWM) automatic voltage regulation and steady speed circuit, DC servo motor drive, large output torque, stable walking, and can maintain stable speed when climbing, vertical crawling and road load changes. Its main parameters are:

Input voltage 220V, frequency 50Hz, overlap width 10cm, power 800W, welding speed 0.5~5m/min, heating temperature 0~450°C, welding material thickness 0.2~2mm, welding width 12.5mm×2, intermediate cavity 12mm, The weight of the whole machine is 5.0kg and the insulation grade is II.

Where the local welding is not possible, or the holes and defects are welded by DSH-XA/C hot air torch. The equipment parameters are: input voltage 220V, frequency 50/60Hz, power 1500W, airflow max230L/min, temperature range 30~700 °C, the whole machine weighs 1.2kg.

3.4.2 Welding parameters

According to the previous on-site welding process test, when the temperature is in the range of 23~33°C, the welding parameters of composite HDPE geomembrane manufacturers should adopt the welding speed of II gear (0.8M/min), the welding temperature is 270±15°C, the speed of III gear is 1M/min, the welding temperature. 300±15°C, IV file 1.2M/min, 330±15°C. On this basis, during the field welding operation, the actual welding temperature and welding speed are fine-tuned according to the site environment.

3.4.3 Horizontal seam welding

Horizontal seam welding uses double seam hot melt welding. The construction method is as follows:

(1) Laying a 3cm thick 30cm wide wooden board at 50cm on the side of the composite high quality HDPE geomembrane as a welding platform for the welding machine. The edge of the constructed composite China HDPE liner manufacturers is unfolded, the geotextile is peeled off, and the welded surface is cleanly cleaned and placed on the wooden board. Then, a composite China HDPE liner factory price to be welded and lengthened is lapped thereon, and the overlap width is greater than 10 cm. When welding after rain, a tarpaulin should be placed on the surface of the fine sand to separate the evaporated water vapor in the fine sand and then lay the wooden board.

(2) Straighten the welding power supply and cable, and place it on the other side. And connect the power to test the condition of the welding equipment.

(3) Check the geotextile peeling at the edge of the composite HDPE geomembrane for sale, as well as the cleanliness and dryness of the welded surface, and clean and dry the welding surface. The weld joint surface must be free of dirt, sand, and water (including dew). Impurities such as impurities affecting the quality of the weld. The film surface of the film surface weld joint is about 200mm. Wipe off dust and dirt with a damp cloth and wipe it clean with clean gauze to keep it clean and dry, and the film should be aligned in parallel.

(4) Measure the ambient temperature, debug the welding equipment, and heat the equipment to the welding temperature. Then, take a small piece of film of 300×600mm for test welding, visually check whether the weld quality is abnormal, and carry out the hand peeling test to determine Soldering temperature (final soldering temperature is within the approved temperature range). When there is a large change in the temperature and wind speed at the site purchase high quality HDPE liner, the parameters should be adjusted in time and the test should be repeated to ensure that the welder performance, site conditions and product quality of the construction meet the requirements of the specification. Generally, not less than twice per day, once in each Before the official operation, once in the middle shift, the experimental welding is carried out under the same surface and environmental conditions as the productive welding. After the on-site peeling test is passed, the formal welding is performed with the adjusted working state. Only through experimental stripping welding, productive welding can be carried out. When welding, the machine head should be aligned correctly, and the welding should not be welded. No welding, leakage welding, jump welding or over-welding is allowed.

(5) After starting the machine, carefully observe the temperature rise displayed by the indicator meter to make the equipment fully preheated. During the welding, the welder should pay close attention to the condition of the weld and adjust the welding speed in time to ensure the welding quality. To keep the welds straight and tidy, take precautions against the unevenness of the film to avoid affecting the smooth operation of the welder. When a special fault is encountered, it should be stopped in time to avoid burning the film.

(6) During the welding process, a special person shall be set up to keep the composite HDPE geomembrane manufacturers stable and prevent the composite China HDPE liner factory price from shifting due to the wind blowing. Two special personnel are set in front of the weld to check the cleanliness between the seams and the weld overlap width purchase high quality HDPE liner. The rear of the welder is set up with 2 to 3 people alternately following the weld to be responsible for the stability of the composite China HDPE liner manufacturers. After the weld temperature drops to normal temperature, it can be evacuated.

3.4.4 Vertical seam welding

Vertical seam welding is mainly for the welding of each composite low price China HDPE liner joint, and the vertical seam welding length is 6m for each welding. The vertical seam welding adopts double-slot hot-melt welding, and the welding method is the same in horizontal seam welding. However, in the welding process, 3-5 persons should be arranged on both sides, and the high quality HDPE geomembrane of 5m on both sides of the composite China HDPE liner factory price weld is unfolded and fixed to ensure welding. The seam is flat until the welded seam reaches normal temperature, and the welded composite wholesale HDPE Liner made in China can be rolled up in the width direction. After the transverse welding is completed, a square 300×300mm patch is welded at the “T” joint to strengthen the joint.

3.4.5 Repair welding

Repair welding uses hot-melt welding, mainly using extrusion welding. For the defects such as pinholes, holes, punctures, serious damage to the membrane surface, sampling points, “T” intersections, wrinkles and other various factors found during the construction of the composite HDPE geomembrane manufacturers, the patches are covered. Method to fix. Repair the composite China HDPE liner manufacturers with the same material, heat the repaired part with a hot air gun, weld from the side of the solder joint to the opposite side purchase high quality HDPE liner, and squeeze while welding so that the repair material and the original material become a whole. Workers should wear insulated gloves when extrusion welding. For different parts, different patches are used for repair welding, as follows:

(1) For defects such as pinholes and holes, the side of the patch should be 10 to 20 cm beyond the damaged part.

(2) When the composite China HDPE liner factory price overlap occurs in the wrinkles, the wrinkles should be removed. If the wrinkle elimination is greater than 10cm, a circular or elliptical patch should be used. The patch size should be 15cm beyond the perimeter of the incision.

(3) A square 300×300mm patch with a chamfered corner should be added at the “T” joint. The right angle of the patch should be rounded, and the patch edge defect should be no less than 10~20cm.

After each weld is welded, the weld shall be visually inspected: lap width, weld width and cavity width between the two welds. The weld shall be smooth and beautiful, straight and smooth purchase high quality HDPE liner, and the weld profile shall be clear. State, no burns, bubbles, virtual welding leaks. The defects found in the composite high quality HDPE geomembrane welding construction and quality inspection process are marked with a paint pen, and the records are repaired one by one according to the defect type.

3.5 Composite geomembrane joint construction

After the welding of the composite low price China HDPE liner is completed, the welding quality is checked and all the holes and defects are processed. After the inspection and acceptance by the supervision engineer, the construction of the geotextile can be carried out. When the geotextile is seamed, the composite HDPE geomembrane manufacturers is first opened and leveled, and the degree of tightness around the geotextile is kept consistent. The edges of the geotextiles of the two-sided composite purchase high quality HDPE liner are erected and folded together, and then the nylon sewing machine is used for double sewing with a portable sewing machine.

4. Conclusion

During the construction process of composite low price China HDPE liner for the dam body of the lower reservoir project of Hebei Fengning Pumped Storage Power Station, the technical test results were obtained through a field test. According to the results of the process test, it is used to guide the on-site construction. The construction quality of the composite high quality HDPE geomembrane of the dam meets the specifications and design requirements, ensuring the anti-seepage quality of the dam body of the sand-blocking dam, and provides a reference for other similar projects.