Discussion on Construction Process Optimization and Quality Control of Plastic Drainage Board

Abstract: Combined with the application of drainage plate combined with preloading method in Xiamen soft foundation dredging and land-filling project, the process and efficiency comparison under different plug-in machine setting conditions are discussed, and the analysis of plastic drainage board is often encountered in the process of setting up. The problems and technical improvement and quality control improvement measures for the problems of plugging and unwinding, not eating belts, positioning offset and other technical difficulties, provide reference and new ideas for the construction and application of plastic drainage boards in large-area projects.

Keywords: plastic drainage board; plug-in machine; rewinding; quality control; port engineering

Introduction

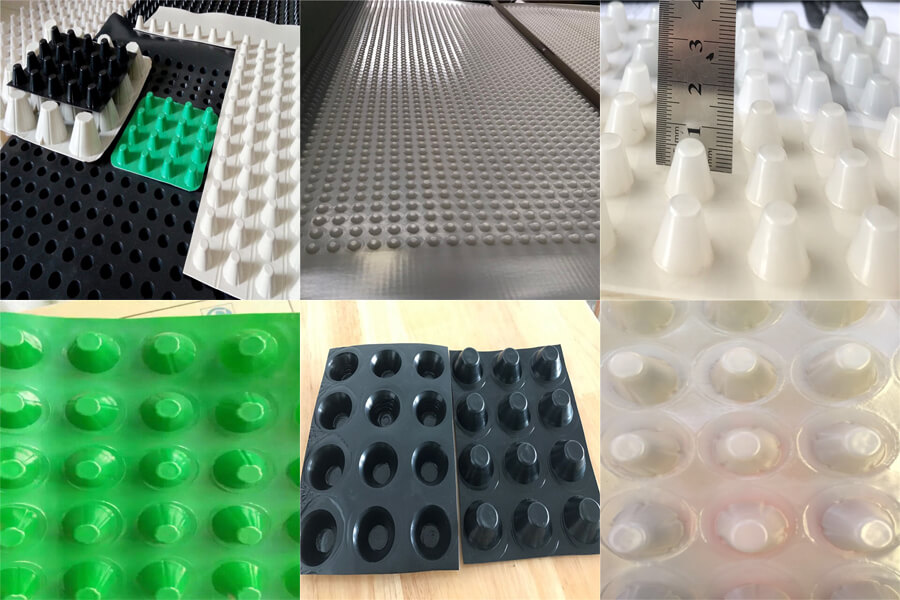

The main action modes of the plastic dimple drainage board for sale combined with the preloading are divided into vertical drainage and vertical pressure: the drainage board is installed in the soft soil to increase the vertical drainage channel, and the drainage system is formed with the upper sand cushion; The additional stress generated increases the pore pressure in the soil, accelerates dissipation through the drainage channel, increases the effective stress, solidifies the settlement of the soil, improves the bearing capacity of the foundation and effectively reduces post-construction settlement.

The design of the plastic dimple drainage board manufacturers is an important part of this reinforcement method. The selection, installation speed and installation quality of the plug-in machine directly affect the construction period, quality and cost of the project [2]. This paper will combine the construction project and efficiency of different plug-in construction tools used in on-site construction with the example of the first-phase project of the large-scale shovel-filling site in Xiamen, and seek through the analysis of the frequently encountered problems and technical difficulties in the construction. Quality control and improvement measures provide reference and new ideas for the construction of plastic drainage boards in large-area projects.

1. Project Overview

The example project in this paper is the Xiaolan Island Landfill Project in Xiamen, which is part of the reclamation project of Xiamen Xiang’ a New Airport, with a total area of about 7.58 km2.

According to the engineering survey geological data, the soil characteristics within the site can be divided into 1 plain fill: light yellow, grayish-white, mainly composed of medium-coarse sand, loose, thickness 0.2-0.6 m; 2 silt Soil: dark gray, saturated fluid state, with odor, thickness 1.5 to 17.9 m; 3 silty clay: grayish-yellow, plastic ~ hard plastic, thickness 1.6 ~ 13.2 m; 4 residual sand: granite weathering deposition products , grayish-white, hard plastic state, thickness 6.6 ~ 9.5 m; 5 fully weathered mixed granite: loose structure, is a very soft rock, thickness 5.5 ~ 6.8 m. The stable water level in the selected field is 1.2 to 1.5 m.

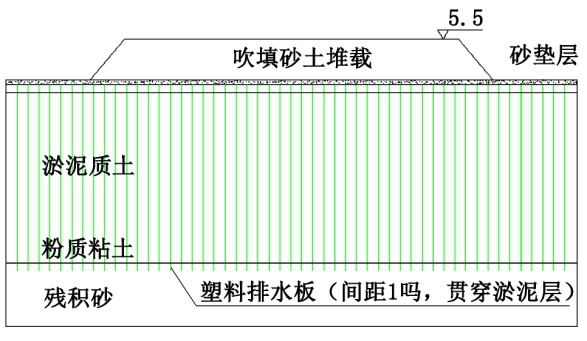

The foundation treatment plan of the project fill-off area is: the suction dredger is dredged to the initial elevation of the site → the sand cushion is formed → the drainage board is set up → the blind ditch, the collecting well → the graded filling and filling to the elevation 5.5 m → Preloading → Unloading → Strong boring and leveling.

2. Analysis of the construction process of plastic slab

2.1 Plug-in model optimization

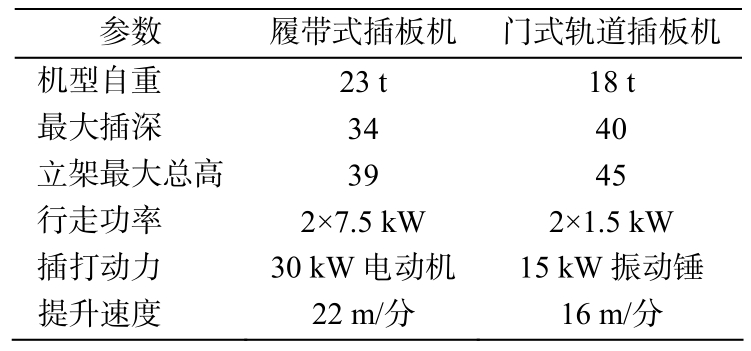

The installation of the drainage board of this project selected two kinds of inserting machinery, namely: crawler type plug-in machine and door type track inserting machine. The main configuration parameters of the two types of plug-in machines are shown in Table 1.

Table 1 Plug-in machine models and their configuration parameters

For the above two types of plug-in machines, the crawler-type plug-in machine is easy to walk, detachable and powerful, but at the same time, there are disadvantages such as the depth of the opening and the verticality are not suitable for control, and the requirements for the strength of the foundation are high. The door type track inserting machine can be disassembled by the whole machine, and the verticality can be adjusted through the track, and the pad can be added at the bottom to make it suitable for the weak field of the foundation strength, but the power is relatively small, and the vibration type is easy to operate. In the case of the instability of the slope foundation, etc., the construction of the drainage plate at the corners is limited by the movement of the rails.

Therefore, combined with the actual construction of the project and the advantages and disadvantages of each plug-in machine, the comprehensive optimization of the plug-in machine is carried out for the combined construction of the track-type plug-in machine and the gantry track inserter. The results show that the crawler static pressure inserting machine carries out drainage board construction in the construction area with small corners, small construction scope, and high foundation strength. The gantry vibration inserting machine has a large construction area and relatively weak foundation strength. The dimple drainage board for sale construction greatly improves construction efficiency and saves the construction period.

2.2 Plastic sheet construction process

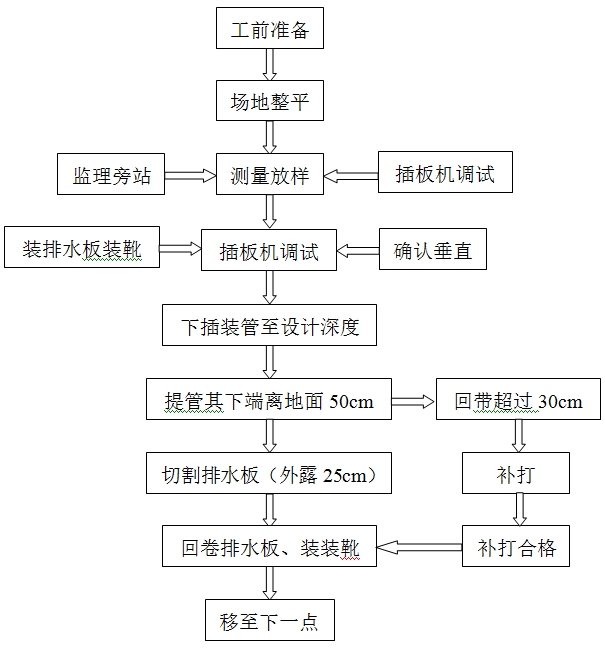

According to the engineering conditions of different fields, the corresponding plug-in machine is preferred to carry out the plugging construction of the dimple drainage board manufacturers. The specific construction process is shown in Figure 1.

Figure 1 Plastic drainage board insertion process

The drainage board of the project is a B-shaped plate with a thickness of 4 mm and a width of 100 mm. The tongue-shaped tear strength of the drainage board is ≥ 60 N, and the filtration coefficient of the outer filter cloth of the dimple drainage board for sale is ≥ 4.5×10-3 cm/s. The plastic slabs are arranged in a square in the installation area with a spacing of 1.0 m. Due to the large area of the entire field and the difference in the thickness of the soft soil in the formation, the depth of the plastic slabs in each field is different. However, the depth of the drainage board is required to penetrate the silt soil layer, and the cross-section of the field area is shown in Fig. 2.

Figure 2 Joint preloading cross-section

3. Construction problems and quality control measures

3.1 Problem Analysis

In the deep soft foundation, especially in the plastic muddy soil, the plastic drainage board is often used, which often causes problems such as blockage of the plug-in machine casing, “returning belt”, “not eating belt” or setting position deviation. It seriously affects the working efficiency and construction quality of the plug-in machine. At the same time, the current plug-in board construction lacks information control, and it is difficult to guide the construction according to the data information.

Through the investigation and statistics of the construction of plastic dimple drainage board manufacturers in multiple sites on the site, the analysis of “returning”, offset and non-entrainment is as follows:

(1) Analysis of the phenomenon of “returning”

The construction of the plastic drainage board is mainly to insert the dimple drainage board for sale into the soft soil foundation through the plug-in machine, and the drainage board is left in the soil by the friction of the soil to the drainage board. The “returning” phenomenon occurs when the downward resistance of the plastic drainage board is less than the pulling friction of the casing and the like, and the drainage board is easily pulled out along with the casing.

The soil layer in this project area varies greatly, and the survey data is not detailed enough. The survey data separated by 200 m can not reflect the soil condition well. The thickness of the silt layer in some areas exceeds or fails to reach (advance into the clay layer). The complex and variable soil condition and the high moisture content of the silt layer increase the construction difficulty of the drainage board, which leads to the phenomenon of “returning” or even “not eating” when the dimple drainage board manufacturers are applied.

(2) Verticality analysis

According to JTS 206-1-2009 water transport engineering plastic drainage board application technical regulations 5.3.3, the vertical deviation of the casing should not exceed 1.5%. The factors affecting the verticality during the construction of the dimple drainage board for sale mainly include the leveling of the foundation and the bending of the casing during the laying process.

The verticality of the casing exceeds the allowable deviation range, which affects the construction efficiency on the one hand and affects the quality of the drainage board installation; on the other hand, it leads to the phenomenon of “returning”. According to the force between the dimple drainage board manufacturers, the sleeve and the soil body, if the casing is perpendicular to the ground, the plastic drainage board is vertically downward under the influence of gravity, and there is almost no friction with the inner wall of the casing. However, if the casing is inclined, the friction between the plastic drainage board and the drainage board increases, and the greater the inclination angle, the greater the frictional force, and the more “returning” phenomenon occurs. Therefore, the verticality of the casing directly affects the construction quality of the drainage board.

(3) Depth analysis

The depth of the plastic dimple drainage board for sale is the main parameter that determines the soft foundation treatment effect and is the key item for the construction quality acceptance assessment. If the depth of the predetermined installation is not reached, the settlement of the soft foundation decreases during the preloading period, the consolidation degree does not reach the requirement, the settlement amount is large at the later stage, and the foundation bearing capacity is low, causing serious consequences.

3.2 Quality Control Measures

The quality control of soft soil-based plastic dimple drainage board manufacturers includes raw material control, construction machinery configuration control, geotextile isolation layer laying control, lower layer cushion paving control, board positioning control, trial control, and board offset Control, board distance control, depth and number of controls, plastic drainage board “return” phenomenon control, vertical degree control, plastic drainage board control, paving upper sand layer control , laying grid control, loading preload control and other aspects of control. This section combines the design of plastic drainage board for soft soil found in the Xiaolan Island of Xiamen. It mainly explains the main aspects of the “returning” phenomenon, verticality control, and depth control.

(1) Quality control measures for “returning” phenomenon

The control of the “return” phenomenon is mainly to increase the downward resistance of the plastic dimple drainage board manufacturers and reduce the upward friction of the plastic drainage board when the casing is pulled up.

The control of the “return zone” phenomenon in this project is mainly to penetrate the silt layer through the on-site plastic drainage board; control the verticality of the card insertion machine; use the steel bar as the pile shoe to improve the anchoring effect of the casing on the dimple drainage board for sale; Reduce the gap between the pile shoe and the nozzle; record the length of the belt back to the belt and take measures such as replenishment to solve the problem of “return belt”.

The details are as follows: In the project, the contact between the pile shoe and the casing is continuously improved, and the contact gap is reduced to reduce the sludge entering the pipe. When pulling on the casing, slow down the speed appropriately to avoid “returning” due to the excessively high speed. Part of the soil layer has large water content, and the resistance of the drainage board is increased by increasing the depth of the installation. In addition, in the area where the foundation changes greatly, the on-site plastic dimple drainage board manufacturers is applied to penetrate the silt layer by about 1 m as the control point. When constructing the crawler-type plug-in machine, it is necessary to arrange for the management personnel to carry out the side station to ensure that the casing sinks to the design depth and the plug-in machine is slightly jacked up to lift the casing; the gantry-type plug-in casing sinks into the process. In the stage of entering the silt layer, there will be obviously accelerated subsidence, and there will be obvious deceleration and vibration intensification when penetrating the silt layer. It is necessary to maintain such slow vibration for about 2~3 s to ensure the depth and quality of the insertion. fulfill requirements.

(2) Control measures of verticality

During the construction process, the verticality control of the casing should be done. The verticality control measures in this project mainly include: flattening the construction site in the early stage and hanging the vertical line on both sides of the inserter casing to control the verticality; for the verticality caused by the casing bending, reduce the machine insert Speed or increase the stiffness of the casing to reduce bending and the like.

(3) Depth control measures

Drainage plate depth calculation formula: S = Sd + Ss + Sh, where S is the length of the dimple drainage board for sale, Sd is the design length, Ss is the exposed length, and Sh is the allowable return length. The depth control in this project is to mark the casing or the frame on the one hand and to control the depth of the drainage board by calculating and marking the position. On the other hand, it is controlled by the scale detection: each of the mounted plastic dimple drainage board manufacturers has a scale, and the length of the drainage board can be determined according to the difference between the top code and the bottom code on the drainage board after the installation. This kind of detection method is the most economical, simple and convenient, and is easy for the construction workers to accept.

3.3 Discussion of related issues

(1) ferrule problem

The project is located in the coastal area, the wind is large, and the plastic dimple drainage board for sale from the ground to the top of the casing is easily squirmed by the wind. In the project, a plastic drainage board ferrule is added to the plug-in machine and the spacing of the ferrules is reasonably arranged so that the dimple drainage board manufacturers remains straight and does not kink.

(2) Plate displacement deviation problem

During the construction of the dimple drainage board for sale, the plane layout of the plastic slab should be measured and staked according to the design requirements. The plane deviation of the setpoint needs to be checked in real-time, which cannot be greater than the design tolerance. However, the current construction is mainly based on the operator’s control. Human factors are inevitably causing problems such as missed hits and large plane offsets. In view of the above problems, the GPS system can be used to divide the construction area, accurately locate the location of each drainage board, and realize the information monitoring and control of the engineering quality, which will also provide an idea for the information construction of the plastic panel.

(3) The problem of high moisture content in the silt layer in some areas

The boots used in this project are made of steel, which is thin, small and heavy. The steel boots are inserted into the mud layer with high water content. If the upward resistance of the mud can not be greater than the weight of the boots, the boots will be loose or even loose. Underneath, as well as the silt entering the barrel, causing the drainage board to be “returned” without the pull-down force, or even the “seat belt” phenomenon. For this kind of flow-like soft clay with high water content, iron skin can be used instead of steel insert boots, and the metal-type boots can increase the soil resistance when the dimple drainage board manufacturers is used, and better “retaining belt”.

(4) Monitoring of the length of the “return belt”

In this project, the current monitoring of the length of the “return belt” is mainly to calculate the “return belt” length by the top code, bottom code, exposed length and design depth of the drainage board scale, and observe the feeding condition of the roller and the extubation through the naked eye. When the drainage plate at the bottom of the casing is exposed, it is judged. Among them, the naked eye observation is only applicable to the judgment of the absence of the belt and the obvious retracement, and the actual “strap” length of the dimple drainage board for sale cannot be accurately known. During the construction period, it is difficult to maintain the construction on-site, and it is more troublesome, time-consuming and laborious to affect the construction period. Therefore, if the drainage board is applied, the worker can accurately read the length of the “return belt” of the drainage board and make up the time in time to improve the progress of the project. Therefore, a monitoring instrument can be set at the drain plate roller of the card inserter, and after reading the sleeve to the design depth, the length of the tape is monitored when the casing is pulled up, and the “return zone” of the drainage plate is directly calculated. The length, the length of the “strap”, and the depth of the display can also be monitored.

4. Conclusion

The vertical plastic drainage board processes the soft soil foundation, and the plastic dimple drainage board manufacturers composed of the drainage core belt and the outer filter membrane is driven into the foundation as a drainage channel to shorten the drainage path, and at the same time, under the action of the upper load, the pore water in the soil layer Through the filter membrane, it penetrates into the groove of the plastic dimple drainage board for sale, and is vertically discharged into the sand cushion layer of the ground along the groove, and then discharged into the temporary drainage ditch through the sand cushion layer to increase the effective stress acting on the soil particles to accelerate the settlement of the foundation is consolidated so that the settlement of the foundation is substantially completed during the preloading.

This paper combines the Dagu Island blow-filling project in Xiamen to discuss the problems often encountered in the project, and to provide a reference for the on-site construction, aiming at the difficulties, the reasons, the technical optimization, and the quality control improvement measures.