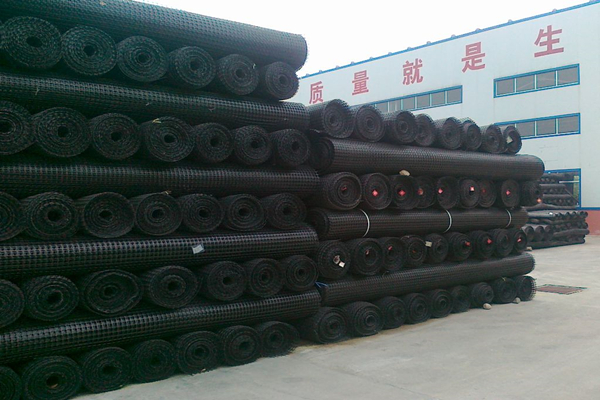

Installation Method and Cautions of Biaxial Plastic Geogrid

Biaxial plastic geogrid when used in roadbed, road surface, the excavation base bed, set up the sand cushion (elevation difference is not more than 10 cm), rolling into a platform, laid grille, longitudinal axial should be consistent with the main stress direction and longitudinal lap 15–20cm, lateral 10 cm, build it with plastic belt binding, and on the laying of the grille, 1.5-2m with U every nail fixed on the ground, laying geogrid should timely backfill material, laying of geogrid layers depending on the technical requirements.

Biaxial geogrid factory price paving surface should be relatively smooth, paving layer after receiving qualified experience, to prevent the longitudinal askew phenomenon, paving layer according to the width in the first draw white lines or hang line, paving, can begin then use nails fixed grid end (every 8 meters wide with nail root, evenly distance fixed), fixed grid after the end, the grille with finisher slowly pull forward shop, shop every 10 meters long for artificial taut and straightening time, until a roll of grille spread out, then spread to the next scroll, with before operation, after laying a roll with 6t – 10t roller rolling forward direction from its starting point again, (such as paving on the surface and the leveling layer, It is advisable to use steel roller; Such as grid directly laid on the concrete pavement, it is advisable to use rubber roller roller,) connect a shop: in roll long as laid long, after should pave grille covered in long, paving quality overall check again, then construct the next section, paving, the next leg of grid and grid can use the lap length of 10 to 15cm, and nails or wedge fixed to go ahead after shop is the second paragraph, so on, with before operation requirements.