Interface Properties of High Density Polyethylene Geogrid and Different Fillers

Abstract: In this paper, the direct shear test is used to compare and analyze the effects of filler type (river sand and gravel soil), water content and positive pressure on the interfacial shear properties of high density polyethylene wholesale biaxial geogrid reinforced soil. The Mohr-Coulomb strength criterion was used to describe the shear strength of the interface between the reinforced soil and the relationship between the shear displacement and shear stress of the interface was established by the modified Duncan-Chang model biaxial geogrid factory price. The results show that compared with the reinforced gravel soil, there is obvious shear stress softening at the reinforced river sand interface. After the biaxial geogrid for sale is added to the river sand and gravel soil, the shear strength is increased by 60% to 70% and 22% to 48%, respectively. The shear strength and shear deformation resistance of the reinforced gravel soil interface is stronger than those of the reinforced river sand. The change of water content of filler has a great influence on interface shear performance and shear stiffness index.

Keywords: reinforced soil; wholesale biaxial geogrid; direct shear test; interface property; shear strength; constitutive model

The interaction characteristics between the reinforced soils are very important for the strength and stability biaxial geogrid factory price of the reinforced soil structure. Factors affecting the interface characteristics of the reinforced soil include the type of filler and its state parameters (compatibility, water content, etc.), the properties of the reinforced material and its structure, and earth pressure. The influence of compaction degree is related to the characteristics of filler. Peng Li et al high quality biaxial geogrid. pointed out that the increase of coal gangue compaction can increase the strength of reinforced coal gangue interface by direct shear test and pull test. Yang Min et al. The degree of compaction has little effect on the direct shear strength of the reinforced soil interface. The influence of water content is also related to the characteristics of the filler. For the reinforced sand, the study shows that the tensile strength of the interface increases greatly with the increase of the water content of the medium sand. However, when the water content increases to a certain value biaxial geogrid manufacturers, the intensity does not change. Large; for reinforced clay, increasing the soil moisture content will reduce the interface strength.

The interface constitutive model between the tendons can be roughly divided into two categories: the full-stage model, and the pre-peak and post-combination models. The full-stage model such as Zhou Zhigang et al. used the Duncan-Chang model and the nonlinear model of Nanjing Hydraulic Research Institute to analyze the interfacial shear performance between the wholesale biaxial geogrid and the soil; the combined model such as Wang Jun et al proposed the intensity peak pre-hyperbolic model and the peak value. The combined model of the displacement softening model is used to analyze the interfacial shear performance between the biaxial geogrid for sale and the soil.

It must be pointed out that with the popularization and application of geotechnical reinforced soil technology, the variety of geotechnical reinforced materials and the types of reinforced soil fillers, it is necessary to test the shear properties of the reinforced soil interface for specific projects. The numerical simulation analysis of soil design and reinforced soil retaining wall structure provides an experimental basis. This paper relies on the application of a new type of high-density polyethylene high quality biaxial geogrid reinforced river sand and gravel soil to fill the reinforced earth retaining wall on a highway in Jiangxi Province, and the interface between biaxial geogrid manufacturers and gravel soil and river sand is carried out. Shear performance test, comparative analysis of the type and water content of the filler, interface normal pressure and other factors on the interfacial shear performance and proposed a constitutive model of the interface relationship between the soil and the soil.

1. Test materials and direct shear test methods

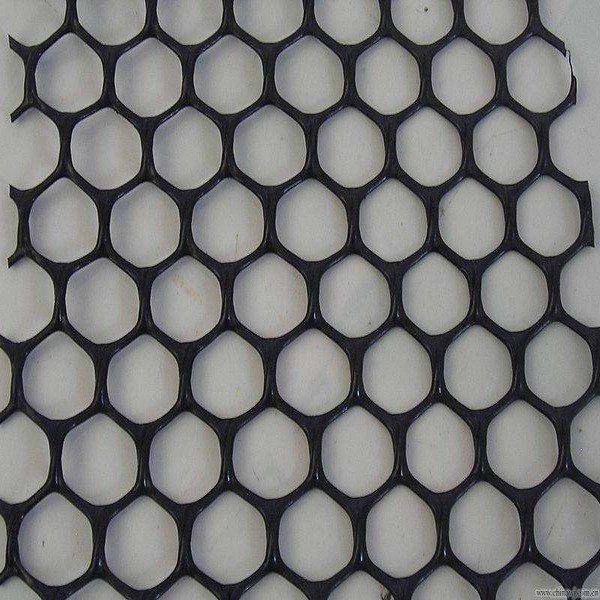

The reinforced earth retaining wall uses a unidirectional high density polyethylene wholesale biaxial geogrid. The mechanical parameters are ultimate tensile strength of 90.5 kN/m, an ultimate elongation of 11.07%, the strength of 28.5 kN/m at 2% elongation, and strength of 52.4 kN/m at 5% elongation. The geometrical parameters are longitudinal rib width 5.7 mm, thickness 1.0 mm, pitch 17.1 mm; transverse rib width 16.9 mm, thickness 2.6 mm, spacing 431.0 mm.

The optimum moisture content of gravel soil is 7.1%, the maximum dry density is 2.12 g/cm3; the optimum moisture content biaxial geogrid factory price of the test river sand is 7.65%, and the maximum dry density is 1.84 g/cm3. The grading of the two fillers is shown in Table 1.

The straight shear specimen has a diameter of 152 mm, a height of 120 mm and compaction of 96%. 3 layers of the top and bottom are compacted. The wholesale biaxial geogrid sample is cut with the transverse rib as the axis of symmetry. The test pieces of four kinds of water content fillers were prepared on the basis of the optimum moisture content of the filler in the indoor sample parts: 5%, 7%, 9%, 11% of gravel soil, 3.5%, 6%, 7.5% of river sand. ,9%. The moisture content of the plain soil samples is 7.5% for river sand and 7.0% for gravel soil.

Table 1 Grades and physical properties of gravel soil and river sand

When performing the direct shear test of the reinforced soil interface high quality biaxial geogrid, the lever type vertical loading method is used, and the positive pressures are 100, 200, and 300 kPa, respectively. The shear loading rate was 1.0 mm/min until the sample broke. During the test, it is ensured that the reinforced transverse rib is perpendicular to the shear thrust direction.

2. Direct shear test results

The shear stress of the interfacial shear stress of reinforced river sand and reinforced gravel soil under different positive pressures in Fig.1 and Fig.2 shows that the shear stress of the reinforced river sand interface and the interfacial shear stress of the reinforced gravel soil reach the peak wholesale biaxial geogrid. The respective shearing displacements are different for the strength, and the latter is larger than the former. When the water content is the same, the interface shear strength and its corresponding shear displacement increase with the increase of the positive pressure. After loading to the peak shear strength, the reinforced river sand showed a more pronounced softening phenomenon than the reinforced gravel soil. If the water content is increased, or a larger normal positive pressure is applied biaxial geogrid factory price, the softening phenomenon of the reinforced river sand is more obvious.

Fig.1 Shear stress-shear displacement curve of reinforced river sand interface

The above phenomenon is related to the phenomenon of shear shrinkage at the interface biaxial geogrid factory price. When the sheer volume and duration are weaker than the high positive pressure at low positive pressure, the shear stress peak and the corresponding shear displacement increase with the increase of the positive pressure. Because the river sand particles are relatively uniform and small, the shearing phenomenon lasts shorter than the gravel soil, so the corresponding shear displacement is smaller when the shear stress peak occurs. It is also because of the characteristics of the composition of the river sand. After the dilatancy phenomenon, it is difficult to maintain a high level of intercalation between the particles, the shear strength is greatly attenuated, and the softening phenomenon is obvious. When the interface shears and slips, the cohesive force loss between the river sand particles and the biaxial geogrid for sale is large, and it is difficult to recover. With the increase of water content, the cohesive force loss is greater, and the clay soil is sticky. The proportion of the particles is relatively large, so the loss of cohesion is small. At the same time, the interfacial friction angle mainly depends on the intermingling friction between the soil particles and between the wholesale biaxial geogrid mesh and the transverse ribs, and the loss after a shear slip is small. Therefore, the shear strength softening phenomenon occurs in the interface during direct shearing, and the reinforced river sand is more significant and becomes more obvious with the increase of positive pressure and water content.

Fig.2 Shear stress-shear displacement curve of reinforced gravel soil interface

3. Interface shear strength

The peak values and asymptotic stability values of the shear stress-shear displacement curves under different positive pressures in Fig. 1 and Fig. 2 are selected as the ultimate shear strength and residual shear strength. The relationship between the peak shear strength high quality biaxial geogrid, residual shear strength and positive pressure of the interface is in accordance with the Mohr-Coulomb strength criterion [Eq. (1)]. Table 2 shows the ultimate shear strength and residual shear strength index of the plain and reinforced soil interface obtained by the linear fitting.

τ=c+σntanφ

(1) Where: τ is the shear strength; σn is a positive pressure; c is the interfacial cohesion; φ is the interfacial internal friction angle.

From Table 2, we can see:

(1) Regardless of reinforced river sand or reinforced gravel soil, their interfacial residual shear strength and ultimate shear strength index internal friction angle and cohesive force all increase first with the increase of water content. After the process of reduction. These indicators increase when the moisture content of the test piece is lower than the optimum moisture content; these indicators decrease when the moisture content of the test piece is higher than the optimum moisture content high quality biaxial geogrid. However, the degree of increase or decrease is different. For example, when the moisture content increases from 5.0% to 7.0%, the friction angle of the residual strength increases by 7.2%, the cohesive force increases by 6.1%, the friction angle of the ultimate strength increases by 7.7%, and the cohesive force increases by 7.7%. When the water content is higher than the optimum moisture content and continues to increase to 11.0%, the friction angle of the residual strength decreases by 12.3%, the cohesive force decreases by 13.7%; the friction angle of the ultimate strength decreases by 14.0%, and the cohesive force decreases by 9.4. %.

This is due to the phenomenon of shearing of the soil at low water content, which is further compacted. At the same time, the surface of the soil particles is generally covered with an adsorption film, which acts as lubrication and has a small friction angle. As the water content increases wholesale biaxial geogrid, the water will further Destroy the adsorption film, reduce the lubrication between the particles, and increase the friction angle between the particles; but as the water content continues to increase, the adsorption film dissolves more thoroughly, and the friction angle increases no longer obvious. The surface forms a water film, which makes the soil particles easy to slip and overlap and exhibits dilatancy, which in turn reduces the friction angle. In addition, when the water content is low, the soil exhibits a certain “cohesion” due to the capillary action of the void water, and the capillary action is further enhanced as the water content increases, that is, the cohesive force is enhanced. However, when the water continues to increase, the excess water molecules will lubricate the soil particles, which will weaken the cohesive force. This also exists between the soil particles and the biaxial geogrid for sale mesh and the ribs. Therefore, the change of water content has a great influence on the cohesive force and internal friction angle of the shear strength index at the reinforced soil interface.

Table 2 Shear strength indicators of plain soil and reinforced soil interface

(2) Under the same conditions, the shear strength index of the unreinforced test piece is lower than the shear strength index of the reinforced interface biaxial geogrid factory price. Compared with the unreinforced test piece, the increase of the friction angle of the reinforced interface is mainly due to the shearing displacement of the filler and the grid interface, and the interlocking effect of the grid mesh on the filler particles biaxial geogrid manufacturers; The improvement of the cohesive force at the reinforced interface is mainly due to the shearing displacement of the filler-grid interface and the friction between the filler particles and the surface of the grid rib. For example, the reinforced gravel soil has a 14.7% increase in residual strength and an increase in friction angle of 25.1%. The ultimate strength cohesion increases by 22.0% and the friction angle increases by 21.2%.

(3) For reinforced gravel soil, since the shear strength is mainly derived from the intrusion friction between the filler particles, the state of intrusion between the particles does not change much with the shearing process, and the internal friction angle is less affected. The residual friction angle is substantially the same as the peak friction angle high quality biaxial geogrid. Although the residual cohesion is reduced more obviously, it still maintains a high level due to more clay components. For the reinforced river sand, because of its different composition with the filler of the reinforced gravel soil biaxial geogrid manufacturers, the residual strength index has a greater degree of attenuation. This shows that increasing the content of coarse particles in the soil can improve the interface friction angle index to some extent.

(4) Regardless of the ultimate shear strength or residual shear strength, the friction angle and cohesion of the reinforced river sand are lower than the corresponding indexes of the reinforced gravel soil. For example, when the water content is 9%, the ultimate strength of the latter The friction angle is 1.35 times that of the former, the cohesion is 6.1 times, the friction angle of the residual strength is 1.4 times that of the former, and the cohesion is 9.2 times. This is because the coarse aggregate particles of the gravel soil are larger or larger than the high quality biaxial geogrid apertures, and the river sand particles are relatively uniform, and the size is much smaller than the biaxial geogrid for sale aperture size, so the gravel soil is embedded between the geogrid and the biaxial geogrid factory price. The friction is stronger. At the same time, there are few clay particles in the river sand, and the clay soil in the gravel soil accounts for a certain proportion. The biaxial geogrid manufacturers in the geogrid hole are more viscous between the biaxial geogrid manufacturers and the gravel soil. Therefore, the reinforced gravel soil exhibits strong interfacial friction and cohesion.

4. constitutive model of reinforced soil interface and its parameters

The relationship between shear stress and shear displacement of reinforced soil interface is one of the important theoretical foundations for numerical analysis of reinforced soil structure biaxial geogrid factory price. For this reason, it is necessary to propose a corresponding interface constitutive model for the shear stress-shear displacement relationship shown in Figs. Because these relationships show obvious nonlinear characteristics, the modified Duncan-Chang constitutive model can be used to describe the nonlinear relationship between shear stress τ and shear displacement δ between high quality biaxial geogrid and soil. The tangent stiffness can be expressed as:

(2) where: k, n are dimensionless parameters; Rf is the failure ratio, the value is generally between 0.5 and 1.0; pa is the standard atmospheric pressure.

The modified Duncan-Chang constitutive model parameters can be obtained by fitting the direct biaxial geogrid manufacturers shear test data, as shown in Table 3.

Table 3 Correction of Duncan-Chang model parameters

From Table 3, we can see:

(1) The k value of the reinforced gravel interface is significantly larger than the k value of the reinforced river sand interface, but the difference between Rf and n is not obvious, indicating that the reinforced gravel soil is more resistant to deformation than the reinforced river sand biaxial geogrid for sale, but Positive pressure has little difference in the contribution of the two to resist deformation.

(2) For the same kind of filler, the change of water content of the filler has no significant effect on the failure ratio Rf but has a significant influence on the shear stiffness index biaxial geogrid factory price, and the change law of k with water content is opposite to that of n with water content.

5. Conclusion

(1) After shear loading to the peak strength, the reinforced river sand shows a more pronounced softening phenomenon than the reinforced gravel soil. If the water content is increased, or a larger normal positive pressure is applied, the softening phenomenon of the reinforced river sand is more obvious.

(2) After adding high-density polyethylene biaxial geogrid for sale to river sand and gravel soil, the shear strength is obviously enhanced. Crushed stone as a filler can provide better interfacial shear strength and resistance to deformation. Crushed stone can be used as a filler for the reinforced retaining structure to save the reinforcement. Increasing the coarse particle content in the soil can improve the interface friction angle index of the reinforced soil to some extent.

(3) The shear strength of the reinforced soil interface is greatly affected by the water content of the filler. With the increase of water content, the cohesive force and friction angle of the reinforced soil interface increase and then decrease biaxial geogrid for sale. The anti-drainage measures should be strengthened in the reinforced soil retaining structure to avoid reducing the shear strength of the reinforced soil interface.

(4) The modified Duncan-Chang model can be used to simulate the shearing process of the reinforced soil interface for numerical analysis of reinforced soil structure biaxial geogrid manufacturers. The change of water content has no significant effect on the damage ratio Rf in the model parameters but has a significant influence on the shear stiffness index.