Application Range of Geotextile

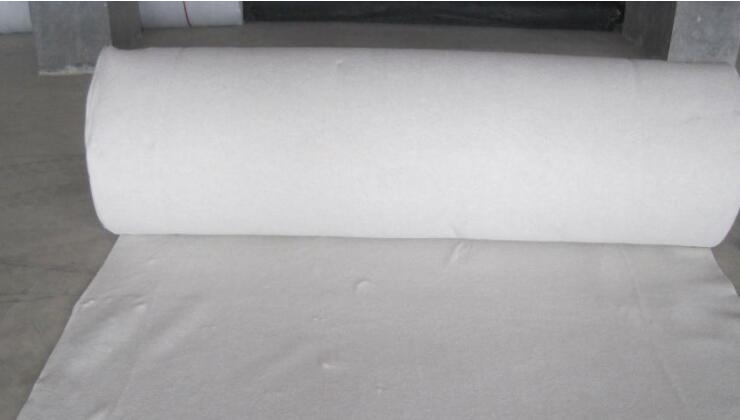

Geomembrane is a new type of environmentally friendly material that has been welcomed by consumers, and geotextiles produced by filament nonwoven geotextile manufacturers can also be seen frequently in various engineering constructions. Geotextiles have been widely welcomed in many industries. , The main scope of use includes the following aspects.

1. Geotextile has the functions of protection, protection, interception, drainage pipes, reinforcement, safety protection, puncture prevention, etc., so it is generally used for reinforcement of railway line foundation, maintenance of road ground, safety protection of fitness gymnasium, Protection of hydraulic engineering construction.

2. For tunnels, coastal areas, tidal flats, reclamation, and environmental protection, etc., the application range is quite wide, and the use time is also very long. It is resistant to corrosion and aging, and there will be no worms. Even in a very hot environment or a cold environment, there is no deformation, strong stability, good permeability, and high tensile strength.

3. Especially in the prevention of soil erosion, the tensile strength and deformation resistance of the soil can be enhanced, so that the structure will be quite stable, its quality will be improved, and the soil will be prevented from being destroyed by external forces. This plays a role in protecting the soil.

Geotextile is made by needle punching or weaving synthetic fiber, so it is very good in water permeability, it can effectively drain the water so that the excess water in the soil structure can be discharged, So as not to stress the structure.

When laying impermeable membranes produced by LDPE geomembrane manufacturers, it is generally required that there must be no wind, because windy weather will blow dust and debris into the impermeable membrane laying layer, resulting in uneven laying of the impermeable membrane, but it is required to have wind and must be constructed At the time, pay attention to certain methods can still be laid.

The method of laying the impermeable membrane in the windy environment, rolling in the direction of artificial safety, filling the soil with the woven bag is convenient for laying, the cloth surface should be smooth, and the deformation allowance should be appropriately left. The installation of filament or short wire impermeable LDPE geomembrane for sale usually uses lap, stitch, and weld methods. The seam welding width is generally greater than 10-15cm, and the lap width is generally greater than 20cm. Geotextiles that may be exposed for a long time should be welded or stitched.

In the case of wind, the stitching of the high quality polyester nonwoven geotextile must be continuous. The pins must be secure. Before overlapping, the geotextile must overlap by 150 mm. The stitching distance is at least 25 mm from the braided edge (exposed edge of the material). The seamed geotextile seam includes a chain suture with a threaded locking device. The sewing thread should be made of resin material with a tension of more than 60N, and it has chemical resistance and ultraviolet resistance equivalent to or exceeding the barrier film. Any “leak stitches” on the stitched polyester nonwoven geotextile manufacturers must be re-engaged in the affected area.

The above is the method of laying the impermeable membrane in windy weather. It is recommended not to lay the impermeable membrane when there is wind. During the transportation of the impermeable high quality environmental geomembrane, the impermeable membrane roll should be protected from damage. The impermeable membrane roll must be repaired when it is physically damaged, and a severely worn impermeable membrane cannot be used.