Mechanism of Geocells and it’s Engineering Application

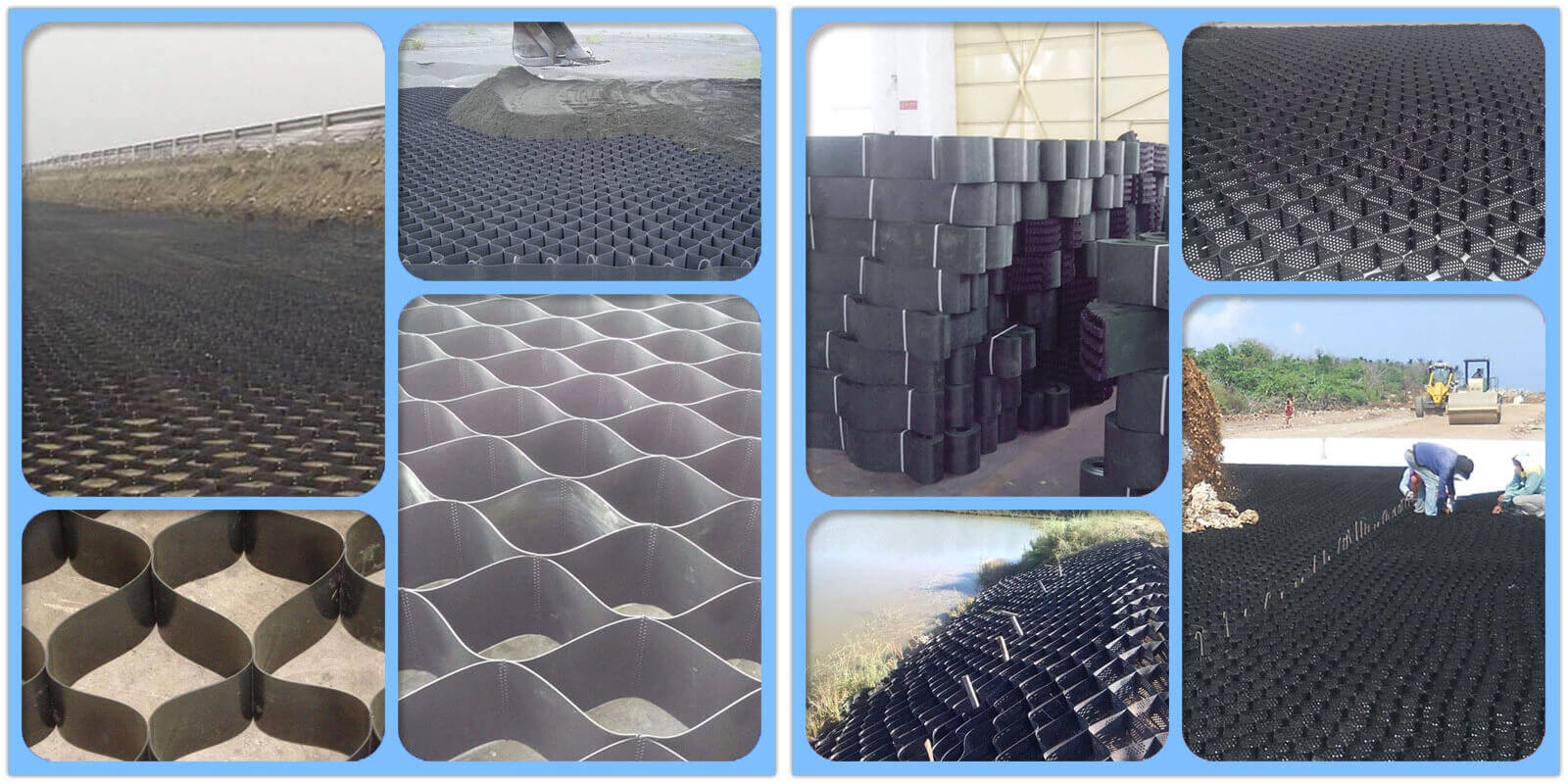

Abstract: In recent years, gravel geocell factory price has been widely used in civil engineering. This paper summarizes the development status of gravel geocell manufacturers by consulting a large number of related literature, and briefly describes the mechanism and application of high quality gravel geocell. Prospects for the application of gravel geocell for sale are made, and relevant recommendations are given for their future research directions.

Keywords: gravel geocell manufacturers; friction; confinement constraint; net pocket effect

1. Introduction

All teaching resources are for the students to learn services, including textbooks, we commonly call the “teaching materials”, all belong to teaching materials. Therefore, the author believes that teachers should not blindly pursue the richness of courseware, and usefulness is the last word. At present, some teaching competition evaluation criteria, “whether or not to use information technology” as a hard indicator, has also led some teachers to blindly pursue the exquisite and fancy of courseware; contrary to this, many teachers have proposed “naked class” to be a measure. Master’s standard. The author wants to say that the teaching methods are not the best, only better, and the teaching resources are “the best is the best”, let the “media information technology” join, truly for our music class “lightening the burden”.

2. Mechanism of geocells

When the gravel geocell factory price reinforcement is not used, if the upper load of the soil reaches the plastic load, the interior is divided into three areas: the active zone, the transition zone and the passive zone, and the soil will undergo shear failure. The shear strength of the soil determines the bearing capacity of the foundation. When the gravel geocell manufacturers are used for reinforcement, the tendency of the plastic zone of the soil to move to the outside is restricted by the compartment, and the movable surface will not continue to develop, thus improving the bearing capacity of the foundation. At the same time, the high quality gravel geocell structure layer can be regarded as a flexible raft foundation with certain rigidity in actual engineering. This will further expand the load on the superstructure so that the additional stress transmitted to the top surface of the weak underlying layer in the foundation is greatly reduced to achieve the purpose of enhancing the stability of the foundation and increasing the bearing capacity of the foundation.

The mechanism of action of the gravel geocell manufacturers is to reinforce the foundation through the interaction between the compartment and the solidification. The interaction is manifested in the following three aspects: (1) The friction between the soil chamber and the filler: part of the vertical load acting on the upper part of the high quality gravel geocell structure, through the frictional force on the interface between the gravel geocell for sale and the filling material Go to the high quality gravel geocell. Then, the diffusion is transmitted outward through the cell, thereby reducing the pressure transmitted to the foundation by the whole system and improving the bearing capacity of the foundation. 2 The lateral restraint effect of the gravel geocell factory price on the soil: when the soil-filled in the gravel geocell for sale is pressed under the load in real-time, the tendency of lateral movement will occur, and the gravel geocell for sale will be tensioned, and then the soil Produces a hoop effect, that is, lateral restraint on the soil. 3 Net pocket effect of high quality gravel geocell: Under normal circumstances, under the action of external force load, the gravel geocell for sale becomes a concave curved surface, and through its tensile deformation, it bears part of the external force, so that the pressure on the concave surface is greater than the pressure under the concave surface. This is the net pocket effect.

Experiments show that there are many factors affecting the geogrid foundation treatment, including 1 the higher the height of the gravel geocell factory price, the smaller the torch, the smaller the cell unit, the stronger the lateral restraint, and the greater the friction of the sidewall. The higher the strength of the gravel geocell manufacturers structure layer; 2 the higher the compaction degree of the filler, the better the reinforcement effect of the high quality gravel geocell. Under the action of compression, it is easy to undergo large deformation, and the gravel geocell for sale can not exert the side effect and friction on the filler.

When the height of the cell is too small or the torch is too large, the effect of suppressing the sliding surface cannot be inhibited, and the shearing slip surface may develop to the structural layer to cause the structural damage of the soil. Increasing the height of the gravel geocell factory price and reducing the torch can prevent the sliding surface from occurring. However, in general, as the height of the cell increases, the compaction of the packing becomes difficult as the height of the cell increases and the torch decreases. Therefore, when selecting the model of the gravel geocell manufacturers, it is necessary to comprehensively consider the cost of the material, the generation of the sliding surface of the structural layer, and the ease of structural lamination.

3. Current status of geocell research

In 1997, Pan Zhenhua proposed that the gravel geocell manufacturers has the function of preventing bed-bed diseases and improving the bearing capacity of the bed. In 2001, Zeng Xiting introduced the mechanism, economic benefits, and application of the high quality gravel geocell in detail. In 2003, Wang Guangyue introduced gravel geocell factory price. The design calculation method, construction technology and application in the slope protection process; in 2004, Xie Yongli and other numerical simulations were carried out by MARC software to study the mechanism of geogrid treatment of uneven settlement of foundation; in 1999, Li Jin et al proposed A new type of composite structure plant protection technology—a geotechnical grid flexible slope protection wall, and the corresponding calculation method is given. In 2013, Xu Tianyu applied ABAQUS software to protect the slope of high quality gravel geocell with different material elastic modulus. The simulation experiment is carried out, and the influence of the elastic modulus of gravel geocell for sale material on the slope stability is obtained. In 2016, Wang Hui applied the nonlinear finite element software ADINA to simulate the work of geogrid reinforced soft soil found in the transition section of road and bridge. The performance reveals the force and deformation law of the geogrid reinforced subgrade.

So far, the research of geotechnical chambers by domestic researchers is mainly based on numerical simulation and field test research for specific engineering applications. However, there is still a lack of exploration on the calculation method of the mechanism of gravel geocell manufacturers, and a relatively complete and systematic design theory has not yet been formed. Although the application of high quality gravel geocell in civil engineering has begun to take shape, the application has not yet formed a complete system, and the relevant national departments have not formulated corresponding standards and specifications for design, testing, and construction. Therefore, it is necessary to carry out a deeper study on the gravel geocell factory price, improve the theoretical system of high quality gravel geocell, and provide a theoretical basis for the formulation of corresponding technical standards.

4. Application of geocells in civil engineering

4.1 Ground treatment

(1) Strengthening the soft soil foundation. At present, the common form of failure of the subgrade is subgrade subsidence. When the filling is good, the use of the gravel geocell manufacturers can limit the buckling deformation of the structural layer, thereby effectively avoiding excessive compression settlement of the structural layer itself. The three-dimensional honeycomb structure of the high quality gravel geocell is combined with the soil to form a reinforced layer, which significantly improves the bearing capacity of the foundation. The experiment proves that the resilience modulus of the soft soil foundation treated by the gravel geocell for sale is 20.2% higher than when the gravel geocell for sale is not used. The gravel geocell factory price can also effectively reduce the dynamic stress, and the dynamic stress of the soil under the foundation of the 0.1m thick gravel geocell for sale can be reduced by 17%. In the construction of a highway in China, the foundation of more than 20 small structures was treated with gravel geocell for sale. After the completion of the construction, the construction unit, the supervisor and the relevant researchers conducted a detailed inspection on the spot, and no settlement cracks were found; the foundations of other small structures that were not treated by the gravel geocell manufacturers were less than half a year after the completion of the construction. Cracks caused by uneven settlement. It can be seen that the use of high quality gravel geocell to treat structural foundations has a significant effect on preventing uneven settlement.

(2) Foundation construction of expansive soil. The application of gravel geocell manufacturers can effectively prevent common diseases caused by expansive soil. The stability of expansive soil is extremely poor, and it will expand during the process of water absorption. When water is lost, it will produce severe shrinkage, which cannot meet the stability requirements of most projects. In general engineering, common expansive soil diseases are manifested in mud-slurry, sinking and external squeezing of the bed, shallow sliding of the slope, and deep sliding. In the prevention and treatment of expansive soil diseases, the gravel geocell factory price is used. Through effective lateral action and friction, the cells and the internal fill together form an elastic structure. When the upper load passes through this structure, the stress is more evenly distributed to the lower part. On the basis of this, the lower foundation stress condition is improved and the foundation deformation is reduced [10].

(3) Handling differential settlement. Because the abutment is stiff and relatively stable, the settlement changes are few; while the subgrade is consolidated for a long time and under the action of the vehicle load, a large settlement occurs with respect to the abutment. Therefore, when the vehicle passes through the bridgehead, bumps occur, which directly poses a safety hazard to the vehicle and the passengers. This phenomenon is known as “bridgehead jumping.” The gravel geocell manufacturers are used to treat the “bridgehead jump”, which effectively reduces the uneven settlement of the subgrade and enables the vehicle to smoothly transition from the bridge to the road. The use of gravel geocell factory price to deal with bridgehead jumping has good comprehensive benefits, not only the cost is equivalent to the ordinary processing method, but also the treatment effect and the service life of the bridge deck are doubled.

The gravel geocell manufacturers are made of high-strength HDPE (high-density polyethylene) strips and are ultrasonically welded. It is a new type of geosynthetic material with a three-dimensional network structure. The utility model has the advantages of simple structure, convenient construction, flexible expansion, and convenient transportation. During the construction, the folded cells are directly pulled into a grid shape, and then materials such as clay and sand are added into the cells, and the filler interacts with the cells to form a whole with a certain rigidity. According to the actual situation of the project, the height of the cell, the welding distance, and other dimensions can be changed to meet different requirements. The gravel geocell factory price is chemically stable and can be used with a variety of substrates under different soil conditions, and is suitable for most parts of China. As a new type of synthetic material, in the late 1980s and early 1990s, Europe and the United States and other countries carried out a lot of research and development work on geotechnical cells. At the end of the 1990s, this technology was introduced into China, and it was first applied in the construction of temporary roads in oil exploration and was later directly used for the construction of permanent roads in desert areas. It was gradually extended to various fields in civil engineering and was widely used.

(1) Protection of embankment slopes. When the possibility of slope collapse is large, the geotechnical chamber can be used for slope protection treatment to achieve the purpose of dispersing the soil weight of the slope surface, reducing the flushing effect and improving the bonding performance between the slope and the soil-based body. When used for slope protection, the expanded compartment forms a layer of retaining wall, which can greatly slow down the water flow and avoid the formation of slope runoff. The network structure of the gravel geocell factory price provides space for the growth of surface vegetation, and the roots of the vegetation from the horizontal connection of the soil, further increasing the stability of the soil. In addition, because of its integrity and certain flexibility, the gravel geocell manufacturers has greatly compensated for the looseness, collapse, and overhead of the stone skeleton protection. It is an ideal geosynthetic material for slope protection.

(2) Construction of retaining walls. As early as 1998, China began to use geotechnical cells for the construction of supporting projects. Compared with the traditional concrete retaining wall, the construction of the retaining wall reinforced by the gravel geocell factory price is simple, the floor space is small, and it can adapt to the deformation caused by poor geological conditions. In the retaining wall constructed by the high quality gravel geocell, the gravel geocell manufacturers is a reinforced material with stable chemical properties, which can effectively resist the erosion of the environment and maintain the stability of the retaining wall. Because the compartment restricts the lateral deformation of the soil, the shear strength of the soil is improved, thereby reducing the thrust of the wall behind the wall and sharing part of the earth pressure.

4.2 Road construction

(1) Road construction in desert areas. Prospecting and oil production often require road construction in desert areas, but the desert is often soft and uninhabited, and the commonly used building materials are scarce. Therefore, ordinary road construction methods are difficult to function and construction costs are high. The use of gravel geocell factory price can effectively solve this problem. First, the high quality gravel geocell is opened, directly fixed on the sand base, and then the sand is taken in place, and then vibrated and crushed. The pavement after construction can meet the long-term use of various heavy trucks. It is easy to operate and extremely efficient.

(2) Road intertidal road construction. If the ordinary road construction method is used in the road construction of the beach intertidal zone, complicated treatment of the foundation is required, and the cost is very high due to the labor cost, and the road strength is not guaranteed. With the combination of gravel geocell factory price and geotextiles, intertidal road construction is a breeze. Firstly, a layer of non-woven geotextile is laid on the beach, and then the high quality gravel geocell is unfolded and fixed on the laid geotextile. The gravel material is filled in the cell, and finally, vibrating compaction forms a permanent road… Even if the road built with the gravel geocell manufacturers is flooded by the tide, its strength will not be greatly affected, which is very suitable for the special requirements of the beach intertidal road.

5. Conclusion

The high quality gravel geocell has a simple structure and convenient construction. Through the friction between the filler, the side effect of the filler and the net pocket effect, the foundation can be effectively treated to meet various engineering requirements. At present, it has been applied to various projects such as foundation treatment, road construction, slope protection and retaining wall construction, which simplifies the construction process, speeds up the construction speed and reduces the construction cost. It is very necessary to deeply study the application of gravel geocell factory price in engineering and expand its application range, especially in areas with extremely poor geological conditions and harsh climates.