Problems Needing Attention in The Construction of Geotextile

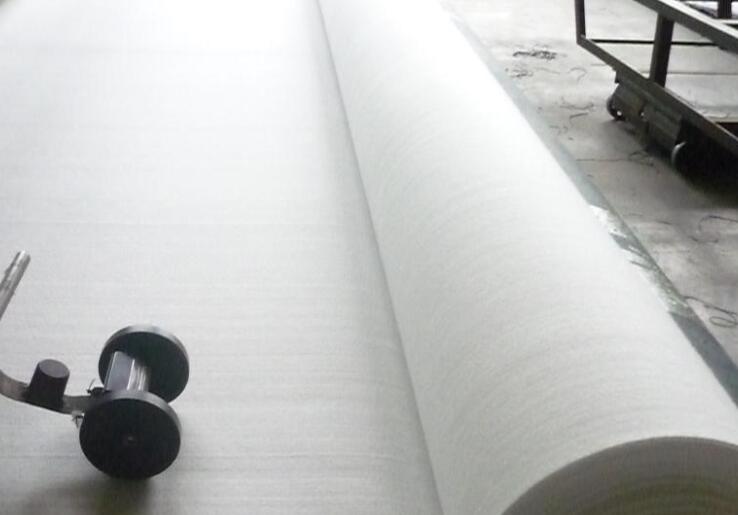

Geotextile is a relatively new type of environmentally friendly material in construction materials, which is composed of synthetic fibers of high molecular polymers such as polyester, acrylic, and nylon. According to the manufacturing method, it can be divided into woven geotextile and non-woven geotextile. The most commonly used in general engineering is non-woven geotextile. In the construction process of high quality filament nonwoven geotextile, it is necessary to pay attention to certain methods in order to maximize its performance.

1. Geotextile laying

The design geotextile material is non-woven filament geotextile, the unit weight is not less than 450g/m2, the tensile strength is not less than 22.5kN/m, and it meets the “Technical Specifications for Geosynthetics Application in Water Transportation Engineering” (JTJ/T239-2005) Claim.

2. Construction equipment

Two 5KW generators (electricity for sewing machine) and five portable sewing machines (on-site filament nonwoven geotextile for sale stitching).

3. Construction process and method

(1) feeding and inspection

Before laying the construction, calculate the area where the geotextile needs to be laid for easy procurement. After the geotextile is purchased, it should be inspected by a qualified inspection laboratory approved by Party A and the supervisor. It can only be put into use after meeting the design requirements. The physical mechanics and permeability indexes of the polypropylene nonwoven geotextile factory price must meet the design requirements. Geotextiles that have been stored for too long or have been aging will not be used.

(2) laying method

① processing, storage

Since the width of the geotextile is generally 2~3m when it leaves the factory, in order to reduce the workload on site and speed up the construction speed, the geotextile is seamed into the laying shape according to the area to be laid, and the industrial sewing machine and nylon thread are used for the wholesale polypropylene nonwoven geotextile. Suture, seam, or over the seam. After the geotextile is processed, it is rolled into a roll and covered to prevent it from aging due to solar ultraviolet radiation. The decrease in strength will affect the laying quality of the geotextile.

② the ground is level

In order to facilitate the laying of the geotextile, before laying the geotextile, the crushed stone surface of the filter layer should be leveled first, and its local flatness is not greater than 100mm. For areas with excessive unevenness, perform manual leveling before laying the polyester nonwoven geotextile for sale, so that the geotextile can be in close contact with the gravel surface, so that the geotextile is in a good state, so as not to affect the laying quality of the geotextile; self-inspection After the measurement, meet the requirements and report to the supervision engineer, and then lay it after confirming with the on-site supervision engineer.

The above are the various issues that need to be paid attention to during the construction of polyester nonwoven geotextile factory price. Only geotextiles laid in accordance with the correct construction method of geotextiles can maximize their performance. It should be noted that sharpness must be prevented during the laying of geotextiles Items will damage the geotextile.