Research on Construction Technology of Geogrid Reinforced Embankment

Abstract: The technical points and compaction technology of wholesale fiberglass geogrid and its reinforced embankment structure and soil grid reinforced embankment are expounded. The test results show that the fiberglass geogrid for sale reinforcement technology can change the constraint of the foundation surface and improve the stability of the slope and the bearing capacity of the foundation.

Keywords: high quality fiberglass geogrid; embankment reinforcement; slope stability; foundation bearing capacity

1. Geogrid and its reinforced embankment structure

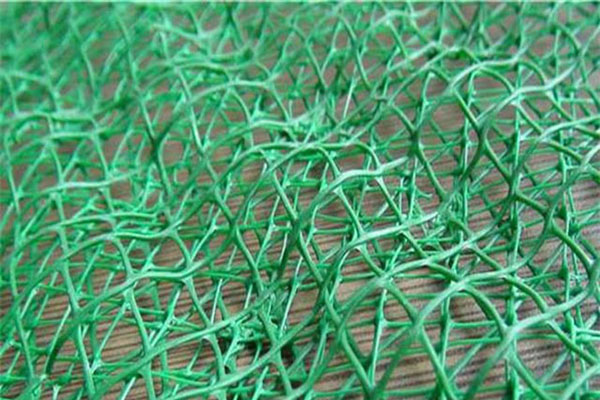

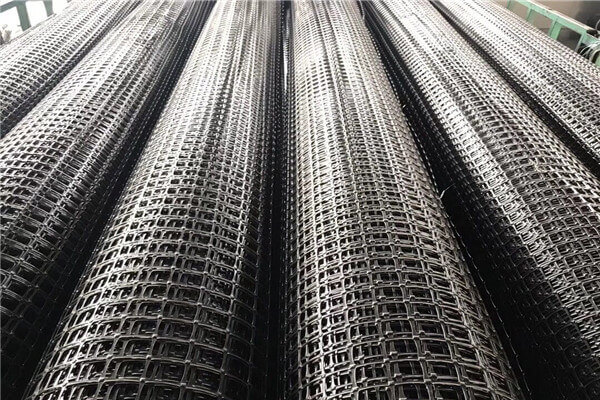

The material used to process wholesale fiberglass geogrid is very special. High density polyethylene (HDPE) or polypropylene (PP) is a material that is often used to make fiberglass geogrid manufacturers. Compared with other geosynthetic materials, the fiberglass geogrid for sale has the advantages of being very prominent, and the overall structure is also very special. The grid is crisscrossed to ensure that the packing can be kept in place, thus ensuring uniformity of the entire foundation. Sexuality has greatly enhanced the carrying capacity of the soil. Because of its many advantages, it is widely used in a series of high-demand applications such as the design of railway embankments and retaining walls. A schematic diagram of two types of high quality fiberglass geogrid is shown in Figure 1.

Figure 1 wholesale fiberglass geogrid one-way and two-way icon

The reinforced soil is also very complicated in construction. In the specific construction process, several layers of reinforced materials are combined by alternately laying.

2. Geogrid reinforced embankment construction technology

2.1 Main points of construction of geogrid-reinforced embankment

The fiberglass geogrid manufacturers are flexible and can be fully utilized in the specific construction process. When working in some special work sites, it is sometimes necessary to connect or cut the fiberglass geogrid for sale into various shapes, and the wholesale fiberglass geogrid Good flexibility makes it easy to meet these requirements.

(1) Cleaning the construction site: Before laying the fiberglass geogrid manufacturers, it is necessary to clean the site first, remove the obstacles on the site, crushed clods, etc., and compact and flatten the foundation with a roller, and also check whether the elevation of the foundation meets the construction standards.

(2) Laying of fiberglass geogrid factory price: When laying fiberglass geogrid factory price on the base surface, it is necessary to follow some technical standards and requirements to ensure that the direction of the embankment axis and the direction of the grid strength are kept perpendicular, thus adding the fiberglass geogrid for sale The ribbed effect is fully exerted. Each joint of the high quality fiberglass geogrid should be kept in a tight and firm state. The tensile strength of the design must be greater than the strength of the joint at the direction of the force. The minimum overlap length should be greater than 15 cm. Only when these requirements are met can the construction be ensured. Safe and reliable.

(3) Filling: The filling process is generally carried out by using an excavator or a loader, and at the same time, it is necessary to ensure that the thickness of the fill is within the specified range. The thickness of the force-receiving part of the equipment and the gap of the grille should be 150mm or more. Only in this way can the wholesale fiberglass geogrid be damaged by the rolling of the construction equipment.

(4) Compaction control: When compacting the surface of the foundation, the optimum moisture content of the fill is about 2%, so make sure that the moisture of the backfill does not exceed this range when filling.

(5) Slope construction: When selecting the treatment plan for the slope surface, it is necessary to fully consider the environment and stress characteristics of the slope surface, and ensure that the slope surface maintains certain erosion resistance and erosion resistance. In addition, the reverse-packed slope structure should keep the shortest length of the grid at around 2m.

2.2 Geogrid reverse construction technology

Although the reverse construction of fiberglass geogrid for sale has a large workload, technical strength, and complexity when the slope of the reinforced embankment is steep, the reverse-construction construction technology must be used, and then the situation shown in Figure 2 and Figure 3 is followed. A comparative analysis was conducted to analyze the advantages of reverse-construction construction technology.

Figure 2 fiberglass geogrid manufacturers do not have a reverse package on the slope

Figure 3 Schematic diagram of the wholesale fiberglass geogrid on the slope and reverse protection and protection

By comparing and analyzing the four cases of Fig. 2 and Fig. 3, it can be found that the benefits of implementing the anti-inclusion technique on the slope surface are obvious. If the slope surface is not subjected to the reverse-package technology, the slope will be washed by long-time wind, erosion, and rain fiberglass geogrid factory price. There will be some damage, resulting in a serious decline in the quality of the slope. When the reverse-construction construction technology is implemented on the slope surface, the above problems can be effectively solved, and the plants on the slope surface can also well reduce the soil loss phenomenon, thereby ensuring the stability and safety of the slope.

3. Geogrid reinforced embankment compaction technology

3.1 Geogrid reinforced embankment compaction standard

The Code for Design of Highway Subgrade (JTJ013-95) is a technical standard that is often used as a reference in the compaction process of fiberglass geogrid for sale-reinforced embankments. The compaction process of the grid reinforced embankment has certain special characteristics in the construction process. Therefore, the following reference standards have been formulated through the embankment construction test, which is listed in Table 1:

Table 1 List of compaction standards and detection frequencies for high quality fiberglass geogrid-reinforced embankments

3.2 Research on geogrid construction damage

Due to various uncertainties at the construction site, this causes the wholesale fiberglass geogrid to be easily damaged by the construction machinery. Once the fiberglass geogrid manufacturers are damaged, its various performances will be seriously degraded, which will affect the construction quality. Therefore, it is generally necessary to carry out a damage test before the construction to determine how the various construction machines will cause damage to the fiberglass geogrid factory price.

The specific construction equipment and conditions involved in this example are as follows:

(1) Self-propelled light wheel vibratory roller and drag-type vibrating horn crusher are the equipment used in this test. The former has a self-weight of 14t and a start-up of 30t. The latter has a weight of 18t and a vibration of 40t.

(2) The matte surface after compaction of the horn roller compactor and the smooth surface after compaction of the roller compactor are the base surfaces laid by the fiberglass geogrid for sale in this experiment.

(3) According to different compaction equipment, different virtual paving thicknesses are set. The horn angle rolling machine has selected 5 different virtual paving thicknesses: 38cm, 30cm, 28cm, 20cm, 14cm. The light wheel roller has selected 3 medium-thickness thicknesses: 45cm, 30cm, and 15cm.

The high quality fiberglass geogrid has a size of 20m×1.5m, a maximum water content of 2%, and a backfill soil water content of 13.5% while ensuring a compaction degree of about 93%. In the test, each virtual paving thickness is taken as a group, and each group is divided into three compacting units. The specific operation process is: static pressure is applied to the base surface by two kinds of rollers, and then used after the static pressure is completed. Vibrating pressure fiberglass geogrid factory price, when the compaction degree reaches about 93%, the soil layer on the surface of the grille is scraped off by a grader, leaving about 5 cm thick, and finally, the artificial soil is used by the construction personnel.

After the test is completed, the grille is slowly taken out from the soil, and then the same size of the grid block is taken in the same part of the three samples and the tensile test is taken. The results after the test are detailed in Table 2 and Table 3:

Table 2 List of tensile test results of civil and wood grids after rolling

Table 3 Statistical table of apparent damage of wholesale fiberglass geogrid construction

Analysis Table 3 can be seen that the fiberglass geogrid manufacturers do not have much influence when using roller compactor. The last column of the observation table can be seen that the number of breaks and damages caused by the roller compactor is very small. At the same time, it is not affected by the thickness of the virtual paving. From this data, it can be concluded that the light roller compactor does not cause excessive damage to the grille. When using the horn roller compactor, the damage and fracture are obviously more than the damage caused by the roller compactor, but when the thickness of the virtual pavement exceeds 30cm, the fracture phenomenon of the grid is also greatly reduced, and the mechanical damage is also greatly reduced. Observing the mechanism of the horn angle roller compactor can be seen that the existing bumps are the main factors causing the damage of the high quality fiberglass geogrid, but the damage can be reduced by increasing the thickness of the dummy slab.

Fig.4 Trend diagram of tensile strength loss of fiberglass geogrid manufacturers with the thickness of fill filler

It can be seen from Fig. 4 that the loss of tensile strength is minimized when the thickness of the virtual pavement reaches 25 cm during the construction of the base surface by using the horn rolling machine, and the tensile strength loss of the grid is lost regardless of whether the thickness of the virtual slab is increased or decreased fiberglass geogrid factory price. Increase. When the thickness of the virtual pavement reaches 30 cm by the roller compactor, the loss of the tensile strength of the grid will be reduced regardless of the increase or decrease of the thickness of the dummy pavement.

Fig. 5 Trend diagram of the loss of fiberglass geogrid for sale elongation with the thickness of the fill

It can be seen from Fig. 5 that when the thickness of the virtual paving reaches 30cm by the roller compactor, the loss of the grid elongation is maximized, and whether the thickness of the virtual paving increases or decreases will increase the elongation of the grid. The loss is reduced fiberglass geogrid factory price. When the construction of the base surface is carried out by using the horn rolling machine, if the thickness of the virtual slab is increased, the loss of the grid elongation is also increased, and vice versa.

After the compaction process is completed, the surface layer on the base surface will have 8cm thick virtual soil layer, and these virtual soil layers will be of no benefit to the construction. If it is not removed, the surface of the foundation will be uneven. Less than construction requirements. However, the mesh of the grille is very large fiberglass geogrid factory price, and then fill in the upper layer can fill the gap through the mesh, so that the soil and the grille of the upper and lower layers can be kept staggered, and the staggered structure will make the grille Ability to maintain interaction with the fill layer. The base surface of the roller compactor after compaction is flat, and the high quality fiberglass geogrid can be laid.

4. Conclusion

The fiberglass geogrid manufacturers keep the packing in place, ensuring uniformity of the entire foundation and greatly enhancing the load-carrying capacity of the soil. The high quality fiberglass geogrid reinforcement technology can change the constraint on the surface of the foundation, strengthen the stability of the slope and further improve the bearing capacity of the foundation, thus largely eliminating the instability of the roadbed.