Settlement Mechanism and Application Analysis of Geocells Treating Soft Subgrade

Abstract: In order to study the influence of different factors on the settlement of the foundation of geogrid reinforcement layer, the indoor model test is carried out from the subgrade with different compaction degree, cell height and weld spacing. The results show that the compaction degree is greater, the subgrade bearing The greater the force; the subgrade bearing capacity increases nonlinearly with the increase of the height of the wholesale HDPE geocell, and decreases nonlinearly with the increase of the grid weld distance. When the height of the cell is 150m and the welding pitch is 500mm, the “cost-effective” for handling the weak subgrade is the highest, achieving economical savings.

Keywords: low price HDPE geocell, compactness, weak subgrade, model test

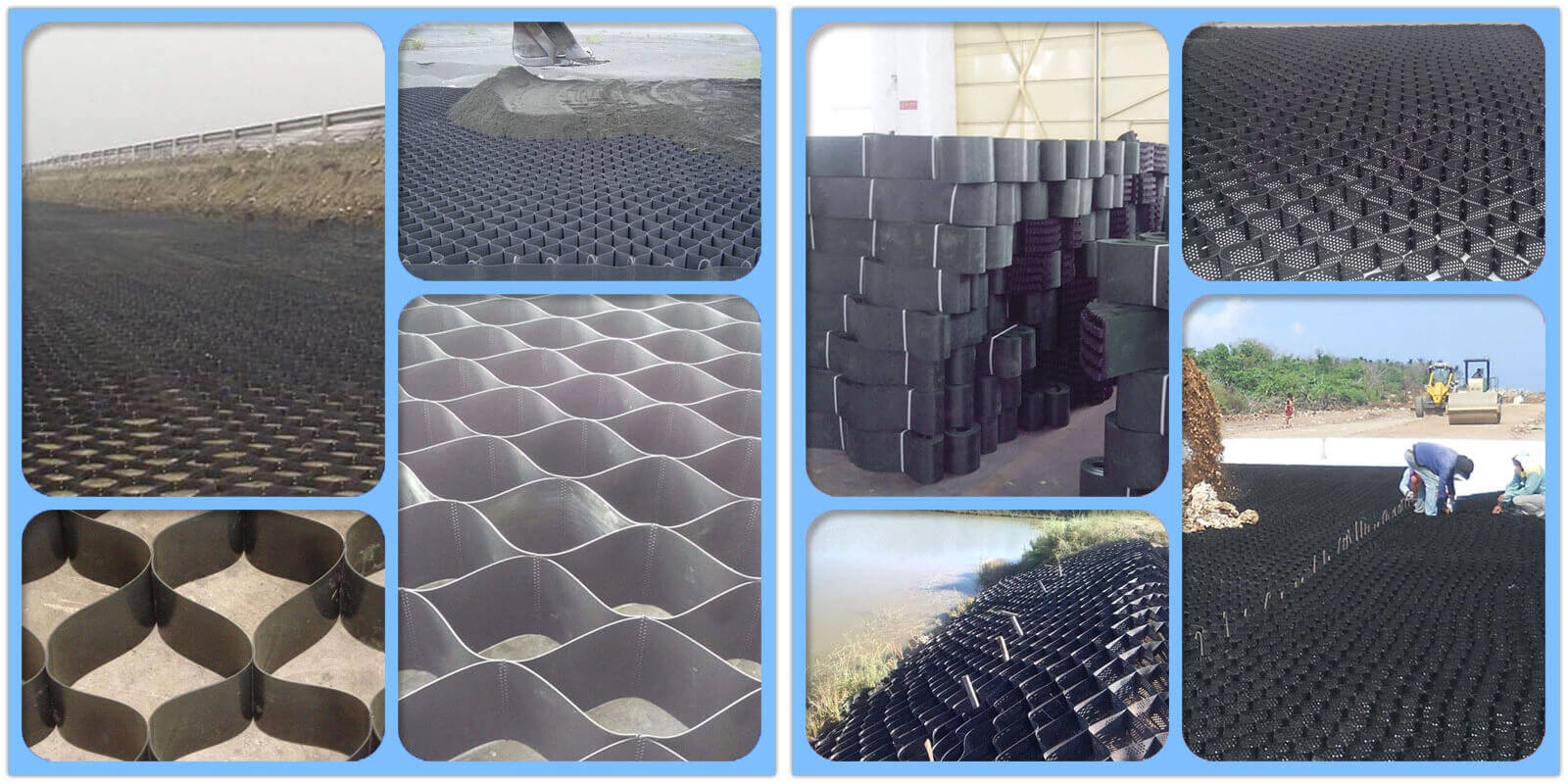

As a new type of three-dimensional geosynthetic material, the HDPE geocell for sale is characterized by lightweight, wear-resistance and convenient transportation. When adding sand, clay, gravel, and other materials to the HDPE geocell manufacturers, it will form a super-strong side. The flexible structural layer with large rigidity is widely used in geotechnical engineering, municipal road engineering, hydraulic engineering, and the like. The laying of wholesale HDPE geocell in the subgrade works can reduce the load spread, the dynamic stress level, and the roadbed stiffness.

The newly-built Xiaoxiang North Road is located on the banks of the Xiangjiang River. The road planning areas are mostly soft base belts such as farmland and marshes. In order to improve and improve the bearing capacity of the roadbed and prevent uneven settlement, it is decided to use high quality HDPE geocell for treatment. Based on the summary of the geotechnical laboratory project, this paper proposes a mechanism for improving the bearing capacity of the subgrade in the low price HDPE geocell and analyzes the HDPE geocell for sale reinforced cushion and subgrade from the mechanical point of view. The reinforcement between the two and the study of the geogrid reinforced roadbed under different factors play a guiding role in the actual construction of the site.

1. Test overview

1.1 Test content

This model test is scientific research carried out by using the wholesale HDPE geocell in the construction of the Xiaoxiang North Road in Wangcheng District, Changsha City to reinforce the weak roadbed. The research contents include the influence of different compactness and cell height on the bearing capacity and deformation characteristics of the subgrade of the high quality HDPE geocell reinforcement layer.

1.2 Test plan

The model slot size used in this test is 2.0m long, 1.25m wide and 1.0m high. The model groove is welded by angle steel. For easy observation, plexiglass is installed on both sides of the model slot, and the two sections are installed. The plate and the inner layer are provided with a water-repellent layer to prevent the water content from changing, and the loading device is equipped on the model groove, and the loading device is a hydraulic jack. The schematic diagram of the model is shown in FIG.

2. Test results and analysis

2.1 Analysis of subgrade bearing capacity of low price HDPE geocell reinforcement layer with different compactness fillers

Through the model slot, the test results of the load plate static load test are obtained, as shown in Fig. 2 and Fig. 3. The results show that when the compaction degree of the fill increases from 84% to 93%, the bearing capacity of the roadbed is from 90kPa to 100kPa. Enhanced to 270 kPa to 280 kPa. This is because the degree of compactness of the filler particles differs under different degrees of compaction. The greater the degree of compaction, the tighter the arrangement between the particles, the greater the interaction between the particles, and the more resistant to deformation. Strong, as can be seen from Figure 2 and Figure 3, as the settlement continues, the bearing capacity will increase. The slope of the curve becomes more and more gradual, and the bearing capacity of the subgrade approaches a certain value, but as the degree of compaction increases, the slope of the curve tends to be less obvious, which indicates that with the gradual degree of compaction When the increase is made, the bearing capacity of the subgrade increases, and the bearing capacity of the subgrade tends to be less obvious. This is because in the reinforced composite structural layer formed by the wholesale HDPE geocell and the filler, the higher the compactness of the filler, the higher the shear strength of the structural layer, thereby strengthening the lateral binding force of the HDPE geocell manufacturers, the sidewall of the compartment and The friction between the fillers increases the friction and cohesion between the subgrade soil and the filler, and prevents the formation and development of the sliding surface in the reinforced composite structural layer, thus promoting the role of the HDPE geocell for sale-shaped foundation and improving the Its subgrade bearing capacity.

2.2 Analysis of subgrade bearing capacity of low price HDPE geocell reinforcement layer with different cell heights

In order to study the influence of the height of the cell on the bearing capacity of the subgrade of the HDPE geocell manufacturers reinforcement layer, the test control is 93% of the same compaction degree. Under the same filling condition, the high quality HDPE geocell size is selected to be 2m (length) × 1.25m according to the size of the test model. (Width), the same welding distance, the height H of the chamber is 50mm, 100mm, 150mm, 200mm, 250mm geotechnical chamber for test analysis, the test results are shown in Figure 4.

It can be seen from Fig. 4 that under the same conditions, the height of the compartment of the wholesale HDPE geocell is larger, and the settlement of the subgrade is smaller under the same load, that is, the bearing capacity of the subgrade of the HDPE geocell for sale reinforcement increases with the height of the compartment. This is because of the higher the height of the HDPE geocell manufacturers, the larger the contact area between the soil and the cell in the same cell, and the greater the lateral binding force of the cell to the weak layer, so the bearing capacity of the subgrade is better.

However, from Fig. 4, it can be found that the bearing capacity of the subgrade increases greatly when the height of the cell increases from 100 mm to 150 mm, and the bearing capacity of the subgrade increases with the increase of the cell height after more than 150 mm. The amplitude is reduced, indicating that the “cost-effectiveness” of the bearing capacity of the reinforcement layer with a cell height of 150 mm is the highest. This is because, when the height of the cell increases to a certain value, although the soil and the contact area of the subgrade increase, the bearing effect is enhanced, the compaction effect decreases with the increase of the thickness of the soil layer, thus causing other cells. The height of the reinforcement layer roadbed bearing capacity “cost-effective” is not the same as the 150mm height of the reinforcement layer roadbed.

2.3 Analysis of bearing capacity of subgrade in low price HDPE geocell reinforcement layer with different cell welding distance

The “high cost performance” cell height obtained in Section 2.2 of this paper is 150mm, and in order to further investigate the influence of the welding distance on the bearing capacity of the high quality HDPE geocell reinforcement layer, the test is also controlled at the same compaction degree of 93%, under the same filling condition, based on the size of the test model was selected from geotechnical cell size 2m (length) × 1.25m (width), cell height 150mm, cell spacing L is 300mm, 400mm, 450mm, 500mm, 550mm, 600mm wholesale HDPE geocell The test results are shown in Figure 5.

It can be seen from Fig. 5 that under the same conditions, when the welding distance is between 350mm and 600mm, the subgrade of the HDPE geocell manufacturers reinforcement layer under the same load, the smaller the welding distance, the smaller the settlement deformation, that is, the larger the welding distance. The subgrade bearing capacity of the HDPE geocell for sale reinforcement layer is smaller.

In Figure 5, the corresponding load value tends to be stable with the increase of settlement, and in order to better describe the bearing capacity of the high quality HDPE geocell roadbed affected by the welding distance, the load-carrying value corresponding to the settlement S=35mm is the analysis object. Figure 6 is drawn. It can be seen from Fig. 6 that the welding distance has a nonlinear relationship with the bearing capacity of the subgrade. That is, as the welding distance increases, the bearing capacity of the subgrade decreases linearly first, and the welding distance increases to 500 mm. At 550mm, the subgrade bearing capacity is reduced faster, indicating that the welding distance of 500mm is the critical value of the curve, and its “price ratio” is higher than other welding pitches.

According to the above test, under the same compaction degree, cell size and filling material condition, the cell height is 150mm, and the subgrade bearing capacity after the reinforcement of 500mm is the highest in cost performance, which can achieve the most economical effect.

3. Analysis of actual engineering application of low price HDPE geocell

Through the experimental model, the best “cost-effective” cell height and weld spacing are obtained. In order to investigate whether the actual strength characteristics of the subgrade after the HDPE geocell for sale treatment can meet the design requirements, it will be tested by on-site compaction and settlement test.

Now take the large-scale soft roadbed at K12+280 of Xiaoxiang North Road as the object, according to the “Code for Design of Highway Subgrade” and design requirements: the compaction degree should be no less than 93%, and the roadbed settlement should not exceed 30cm. Through field test, the test results of the test results are shown in Table 1, for the weld subgrade compaction and settlement after the welding distance × height is 500mm × 150mm, 550mm × 150mm, 500mm × 100mm, 450mm × 150mm, 500mm × 200mm. Table 2 shows.

Among the different subgrades and heights, the softness of the subgrade compaction and settlement values are all the pass points of the weld height × height of 500mm × 150mm, and the average compaction degree is 94.05%, the average settlement is 19.61cm; and the weld height × height is 550mm × 150mm and 500mm × 100mm have points where the degree of compaction is unqualified. The weld height × height is 450mm × 150mm and 500mm × 200mm compaction degree and settlement value are all qualified, but compared with 500mm × 150mm, the compaction degree and settlement value satisfy the requirements are not obvious.

Taking into account the economic benefits, specifications and design requirements, in summary, the best cell height and welding distance in the actual construction of the project are obtained, and the geotechnical chambers have a certain promotion and guiding significance for the construction of weak roadbed construction, and similar The project serves as a reference.

4. Conclusion

In this paper, the model test of the bearing capacity of the embankment strengthened by wholesale HDPE geocell is carried out by different degrees of compaction, cell height, and welding distance. The relevant conclusions are obtained and verified by actual test on-site. The main results are as follows:

(1) Under the same conditions, when the compaction degree of the fill in the high quality HDPE geocell reinforcement layer increases from 84% to 93%, the bearing capacity of the subgrade increases from 90 kPa to 100 kPa to 270 kPa to 280 kPa, which is compacted in the HDPE geocell for sale reinforcement layer. The degree has a great influence on the bearing capacity of the roadbed.

(2) When studying the influence of the height of the cell and the welding distance on the reinforcement layer of the HDPE geocell manufacturers, the larger the height of the cell and the smaller the welding distance, the greater the bearing capacity of the soft subgrade after the treatment of the high quality HDPE geocell, but the height of the cell is 150mm. When the welding distance is 500mm, the “cost performance” is the highest.

(3) It is found through the different cell heights on the site, the actual compaction degree and settlement value of the roadbed after the welding distance treatment and the soft roadbed treated at the welding distance × height of 500 mm×150 mm satisfies the compaction degree of not less than 93%. The actual requirement of the settlement is less than 30cm, and the economic effect can be achieved.