Stress Analysis of Multi-funnel Synchronous Ore-concentrating Flexible Insulation Layer Based on Indoor Model Test

Abstract: The analysis of the mechanical characteristics of flexible insulation materials under multi-funnel ore mining conditions is the basis of the study of the ore-mining mechanism. Based on the indoor model test, the tensile stress and compressive stress of the insulation layer in the test were measured bentonite geosynthetic clay liner for sale, and the stress characteristics and failure conditions of the insulation layer were analyzed. The results show that: 1) In the lateral direction, with the increase of the distance between the measuring point and the center point of the isolation layer, the variation bentonite geosynthetic clay liner manufacturers trend of the internal tensile stress value of the isolation layer is consistent with the sinusoidal function; the compressive stress value of the isolation layer is gradually reduced, and the friction is affected. The force value changes in the shape of the cosine function high quality bentonite geosynthetic clay liner; the isolation layer corresponding to the cavity part is not supported by the supporting force, and the variation of the supporting force load of the other part of the isolation layer is consistent with the compressive stress; 2) in the longitudinal direction, all acts on the isolation layer The force value increases with the increase of the depth of decline; before the isolation layer contacts the bottom structure, the internal average tensile stress increases exponentially with the decrease of the depth wholesale bentonite geosynthetic clay liner; the relationship between the tensile stress and the depth of the isolation layer is σsmax =-0.32+0.32e0.005h, the failure point of the isolation layer satisfies the equation s=±30.12cm.

Keywords: synchronous filling; indoor model test bentonite geosynthetic clay liner factory price; flexible insulation material; force characteristics; failure point

The mining and mining method is a mining method suitable for mining steeply inclined thin deposits bentonite geosynthetic clay liner for sale. It is widely used in China’s non-ferrous metal mines, especially small and medium-sized mines or large mines with suitable mining conditions. However, due to the fact that the goaf is not treated in time during the use of the ore retention method, severe ground pressure activities may occur. In order to effectively control the ground pressure caused by the existence bentonite geosynthetic clay liner factory price of the empty field and the delayed filling after the flood, the author proposed in 2010 a large-scale ore-filling synchronous filling and filling method without pillars. Different from the traditional ore-mining process, the new mining method lays a flexible isolation layer on the surface of the retained ore pile before a large amount of ore-extracting, which causes the flow law to break through the description range of the existing ore-mining theory. Therefore, the bulk medium flow under the flexible isolation layer is carried out high quality bentonite geosynthetic clay liner. Theoretical research is of great significance. Among them, the analysis of the mechanical characteristics of the multi-funnel ore deposit flexible isolation layer is an important part of the new ore-concentration theory research.

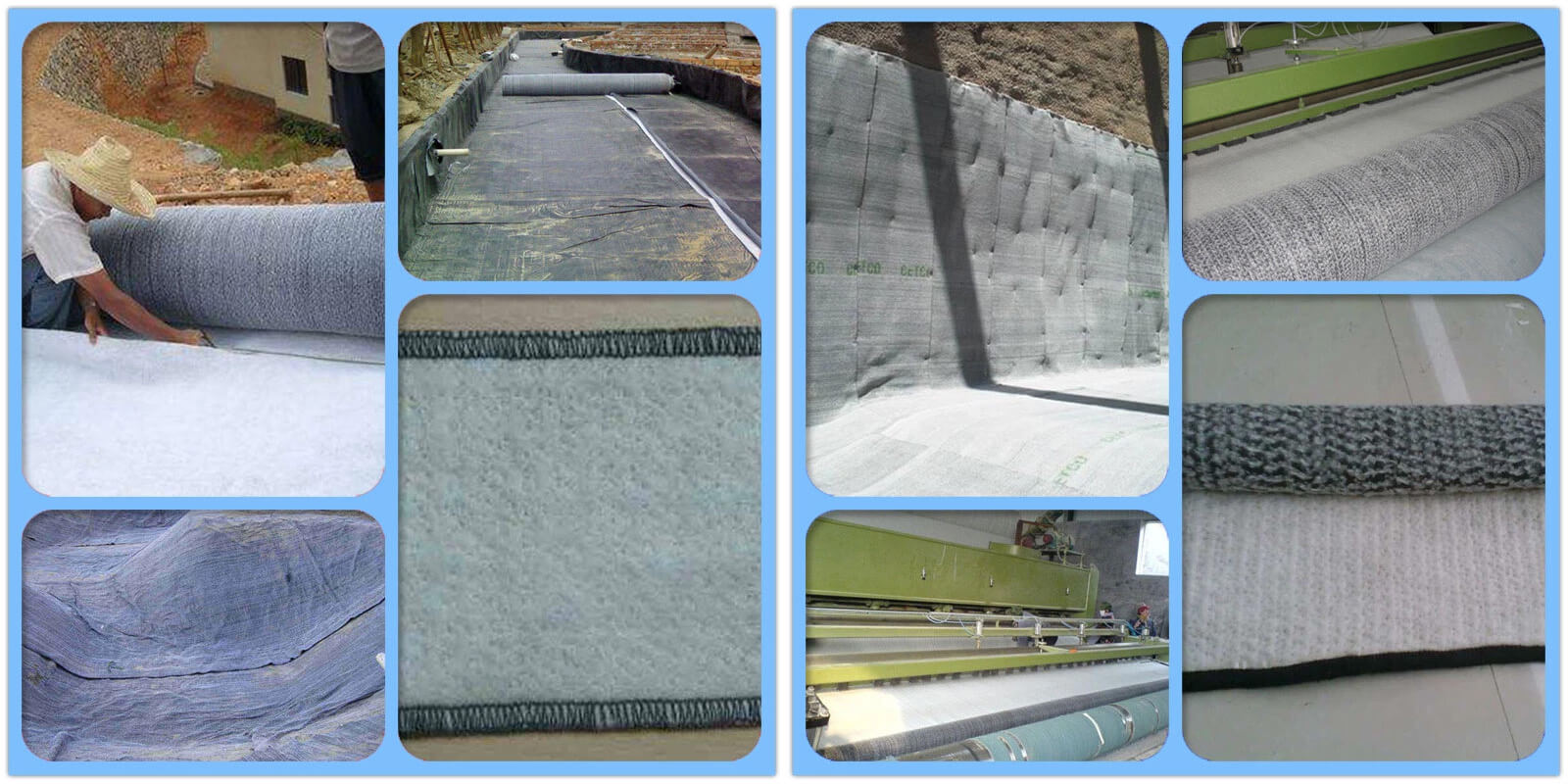

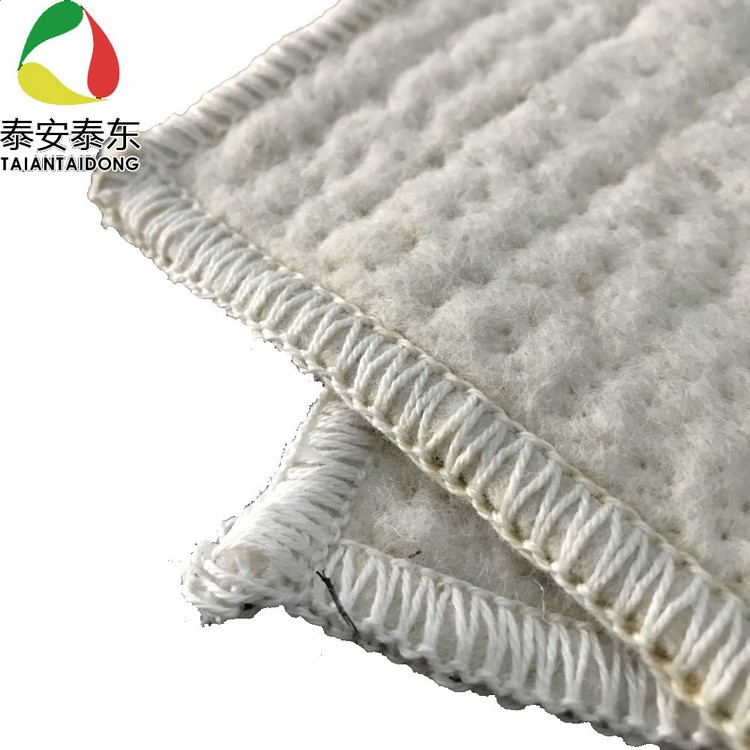

In the aforementioned invention patent mining method, it is recommended to use a flexible material such as geotextile bentonite geosynthetic clay liner for sale, rubber, synthetic material, etc. which has the advantages of high strength, corrosion resistance, and low flexibility. Such materials are currently widely used in stacking projects, seepage prevention projects, road works, and the like. For example, Liu Huabei discussed the internal force analysis methods of several geosynthetics reinforced soil retaining walls, and commented on the advantages and disadvantages of different methods. Hu Liwen analyzed the infiltration of geotextiles from the perspective of strength loss during long-term operation wholesale bentonite geosynthetic clay liner. Sex, soil conservation and clogging performance; Chen Shannon et al. proposed the finite difference calculation using the elastic film theory of geotechnical reinforced dams, and compiled the calculation of the geotechnical force and the actual distribution of soil friction and its stability to the seawall. Impact; Bergado et al. evaluated the tensile load caused by geosynthetics by limit equilibrium method, limit method and simple combination method; Wasti et al. used geomembrane anti-seepage geotextile with sloping plate shear strength parameters for direct shear box Experiment; Qian et al. studied the effects of different load combinations and temperature changes on the performance of geotextiles to retard the reflective cracking of asphalt pavements through indoor fatigue tests high quality bentonite geosynthetic clay liner; Abdul et al. used jute geotextiles to layout rural roads in different locations in Bangladesh and found that different sections were added. Carrying capacity is 1.5 times to 7 times of the original, improving economic efficiency and resistance Long-lasting; Clemente et al. used multi-functional geotextiles and tested along the railway near Chemnitz, Germany, and found that geotextiles provide reinforcement and monitoring. Correspondingly, the study bentonite geosynthetic clay liner factory price of the stress characteristics of these materials is mainly concentrated in the structure and geotechnical fields. For example, Tan Ping et al. discussed the non-axisymmetric bending problem of curved fiber-reinforced composite annular plates based on the classical plate and shell theory. Li Qinghua et al. studied the super high toughness cement matrix composite by using the split Hopkinson pressure bar device. The mechanical response of the material under high-speed impact compression stress; Shi Jianyong et al. Geomembrane and sand, geomembrane and clay, geotechnical geomembrane, geotextile and sand, and interface bentonite geosynthetic clay liner for sale, respectively, in the landfill Pulling test of sand and sand, geotextile and clay bentonite geosynthetic clay liner manufacturers, direct shear test and single shear test of geonet-geomembrane-clay combination; in order to study the mechanical properties of the liner on the slope, Muller et al. developed a slope of 1:2.5 The bevel shear tester was used to carry out the long-term shear strength test of geotechnical composite bentonite liner (GCL); Mizyal et al. used a slant plate tester and a traditional direct shear device to compare different textures of HDPE film with sand of different traits. The characteristics were compared and tested; McCartney et al. evaluated the shear strength of synthetic clay liners (GCLS) and geomembranes (GMs) based on the 534 large direct shear test results database. And research wholesale bentonite geosynthetic clay liner.

Based on the research status at home and abroad, the related research on bentonite geosynthetic clay liner factory price flexible materials such as geotextile and rubber is limited in the mining process. Fan Manhua uses the woven plastic cloth to lay the shorter length of the stope and the artificial mining area, thus making up for the shortcomings of the paving cement slurry bentonite geosynthetic clay liner for sale; Hou Jianhua introduced the characteristics of several padding materials in the dry filling mining method, and made an optional evaluation of each bedding material. In the study of the ore-mining process, the author obtained the interface morphology of the single funnel ore deposit flexible isolation layer by Gaussian model and theoretical derivation wholesale bentonite geosynthetic clay liner.

In order to further enrich the application of flexible materials in ore mining, this paper takes the flexible insulation layer material as the research object bentonite geosynthetic clay liner manufacturers, studies the mechanical properties of the isolation layer under multi-funnel ore mining conditions high quality bentonite geosynthetic clay liner, analyzes the distribution characteristics and variation laws of each force system, and is flexible in the new mining method. The strength design of the isolation layer provides a theoretical basis.

1. Test materials and methods

1.1 Test model

In order to study the mechanical properties of the multi-funnel ore-concentrating flexible barrier wholesale bentonite geosynthetic clay liner, a similar model was made according to the similarity first theorem at a 1:25 similarity ratio (see Figure 1). The model simulates a standard nugget with a length, width, and width of 200 cm x 160 cm x 24 cm. The basic frame material of the model is mainly composed of different types of angle steel, flat steel, and iron plate welding bentonite geosynthetic clay liner for sale. The front PC endurance board draws the corresponding coordinate grid, and the rear PC endurance board is cut into three equal parts for the test; the bottom structure consists of 7 funnels, the spacing between the funnels is 24cm, and the funnel size is 8cm×8cm; The ore-mining function is to install a long strip at the funnel opening to vibrate the board up and down bentonite geosynthetic clay liner manufacturers.

1.2 Test materials and instruments

The ore used in the test was limestone bentonite geosynthetic clay liner factory price, which was crushed at a similar ratio of 1:25. The average blockiness was 2 cm, the density was 1530 kg/m3, the humidity n was 0.14%, the natural angle of repose was 35.8°, and the internal friction angle was 41.5. A silicone rubber having a length high quality bentonite geosynthetic clay liner, a width and a thickness of 170 cm × 24 mm × 2 mm was selected as the flexible separator.

Figure 1 indoor test model

The experimental collection equipment includes 2 sets of YJZ-32A intelligent digital strain gauges, 15 miniature earth pressure boxes, strain gauges, and wires wholesale bentonite geosynthetic clay liner.

1.3 Test plan

The measuring points are arranged on bentonite geosynthetic clay liner manufacturers the upper surface of the isolation layer, and the measuring point arrangement is as shown in FIG. 2. When collecting the transverse tensile strain, two strain gauges with opposite and parallel ore body orientations are fixedly arranged at each measuring point (average of multiple measurements), and then the wires connecting the strain gauges are connected in order from left to right. Enter the corresponding channel of the strain gauge high quality bentonite geosynthetic clay liner. After the model is filled, the isolation layer with the strain gauge is laid flat on the ore surface. During the experiment, all the funnels were opened, and the ore particles were slowly released by vibrating the boards up and down. Each time a certain amount of ore was released, the waste rock was backfilled to the initial height of the model in time to achieve synchronous filling bentonite geosynthetic clay liner for sale, and the data was collected by the strain gauge until the ore could not be released. When longitudinal compressive strain is collected, a pressure box is fixedly arranged at each measuring point of the isolation layer, and the remaining steps are consistent with the steps of bentonite geosynthetic clay liner factory price collecting the transverse tensile strain. Due to the symmetry of the isolation layer, only the force measurement values on the right side of the test were taken for analysis.

Figure 2 isolation layer measurement point layout/cm

The stress of the isolation layer is related to the volume bentonite geosynthetic clay liner factory price, density, shape, and size of the mineral material and its randomness. This experiment was repeated several times to reduce the influence of randomness on the conclusion. In many experiments, the volume and density of the mineral material The shape and size are all determined values. Therefore, the test can analyze the relationship between the stress and the falling height h of the isolation layer during the descending process high quality bentonite geosynthetic clay liner, and then reflect the stress evolution law and breaking conditions of the isolation layer.

Because the similar test model is low in cost, maneuverable, and has certain reliability when the geometric similarity wholesale bentonite geosynthetic clay liner, mechanical similarity, and initial state are satisfied, the conclusion of this test can provide a bentonite geosynthetic clay liner manufacturers reference for the selection of the engineering site isolation layer.

2. Test results and analysis

2.1 Analysis of the particle system of the isolation layer

In the multi-funnel ore-concentration experiment, the initial deformation of the ore is gradually deformed and bent wholesale bentonite geosynthetic clay liner. The barrier layer is always in close contact with the highest ore surface and is kept gently moving down together. When the highest ore surface drops to a certain depth, the highest ore level begins to appear uneven; as the ore surface continues to decline, the uneven phenomenon becomes more and more obvious bentonite geosynthetic clay liner for sale, and the separation layer and the ore surface are separated in some spatial parts; When no ore is released from each funnel opening, the separation layer is suspended in a wavy shape on each of the funnels, and there is no residual of the pure ore of the ridge in the stop due to the obstruction and smoothing of bentonite geosynthetic clay liner factory price the separation layer. Part of the mining experiment is shown in Figure 3.

Figure 3 Multi-funnel synchronous filling and ore section

In the test, the isolation layer is subjected to the pressure of the waste rock, the support force of the loose rock and the friction generated by the waste rock and the loose rock to the isolation layer, the tensile force of the isolation layer, and the force of a micro-stage isolation layer high quality bentonite geosynthetic clay liner. As shown in Fig. 4, σs is the tensile stress of the micro-segment, dσs is the tensile stress increment, θ is the angle between the tensile stress direction and the tangential direction of the micro-section of the isolation layer, and q1 is the compressive stress. Q2 is the supporting force, and f1 and f2 are the upper and lower surface frictional forces, respectively wholesale bentonite geosynthetic clay liner.

Figure 4 isolation layer micro-section force analysis diagram

The test slowly releases the ore particles and controls the release rate of the ore at a near-zero level bentonite geosynthetic clay liner for sale, so the influence of the system acceleration is neglected, that is, the force F of the isolation layer approaches the equilibrium state during the lowering process:

2.2 Analysis of each component force

(1) Analysis of tensile stress

The transverse tensile strain data collected by the strain gauge can obtain the values of the strain bentonite geosynthetic clay liner factory price gauges of each measuring point of the isolation layer at each falling depth h. The strain value is analyzed and processed, and the tensile stress values of each measuring point of the isolation layer are obtained, as shown in Table 1.

Table 1 tensile stress data table of each measuring point of the isolation layer wholesale bentonite geosynthetic clay liner

The experimental data of each descending depth of Table 1 were analyzed by Origin, and the sine function fitting effect was the best high quality bentonite geosynthetic clay liner. The general formula is as follows:

Equation (2) gives the general formula of the tensile stress curve function of the isolation bentonite geosynthetic clay liner factory price layer under each falling height. In order to facilitate the observation of the evolution process of the tensile stress function of the isolation layer, the center point of the isolation layer is taken as the coordinate origin, and the isolation layer is established wholesale bentonite geosynthetic clay liner. The length s is the horizontal axis, the tensile stress σs is the coordinate system of the vertical axis, and the tensile stress function curve of the isolation layer under each falling depth his plotted in the same picture (see Fig. 5).

Figure 5 pull stress value function curve

Through the above analysis bentonite geosynthetic clay liner manufacturers, the expression of the tensile stress function of the isolation layer at each depth of decline can be fitted with high quality bentonite geosynthetic clay liner. The fitting parameters of the tensile stress function of the isolation layer at each falling depth are shown in Table 2.

Table 2 Fitting parameters of the tensile stress function of the isolation layer

Using Origin to analyze the relationship between the fitting parameters of Table 2 and the falling depth of the isolation layer, respectively wholesale bentonite geosynthetic clay liner, the functional formula of each parameter 0σ, A, s0, w in the process of ore mining can be obtained as follows:

Substituting equations (3) to (6) into equation (2), the internal tensile stress function bentonite geosynthetic clay liner manufacturers of the entire isolation layer of the ore discharge can be obtained as follows:

It can be seen from equation (7) and in conjunction with FIG. 5 that, under the same descending depth, as the distance between the measuring point and the center point of the isolation layer increases, the variation trend of the tensile force in the isolation layer is consistent with the sine function bentonite geosynthetic clay liner for sale; when the falling depth changes, the isolation layer is pulled inward. The stress value increases with the decreasing depth, which indicates that in the engineering of equal spacing funnel arrangement, the tensile stress of the isolation layer conforms to the sinusoidal function model at the same falling depth bentonite geosynthetic clay liner factory price, and the stress value and the falling depth of each point increase exponentially.

The average tensile stress value of the isolation layer in the multi-funnel physical test reflects the overall bentonite geosynthetic clay liner manufacturers tensile deformation of the isolation layer, which has guiding significance for the selection of engineering design materials high quality bentonite geosynthetic clay liner. The average tensile stress values of the isolation layer at each falling depth are shown in Table 3. For the data in Table 3, a regression analysis (2 = 0.967 R) was performed, and the results are shown in Fig. 6.

Figure 6: Average tensile stress value fit curve

It can be seen from Fig. 6 that the average tensile stress of the isolation layer and the falling depth bentonite geosynthetic clay liner factory price of the isolation layer increase and increase exponentially. The fitting formula is shown in equation (8), indicating that the height of the designed mine height is larger, and the strength requirement of the isolation layer is required high quality bentonite geosynthetic clay liner. The higher, so in the actual construction, the height of the mine should not be too large.

(2) Analysis of compressive stress

The longitudinal compressive strain data collected by the strain gauges are used to measure the strain values of the highest ore level at different depths of decline. Combined with the rate determination coefficient of the pressure box, the compressive stress values of bentonite geosynthetic clay liner factory price each measuring point at each falling depth are obtained, but the data processing finds the measured value. The point tilt causes the pressure box to actually contact the fluctuation of the force surface, and the reading error is large bentonite geosynthetic clay liner for sale. In order to obtain more accurate test data, learn from the experience of the German engineer Janssen using the continuum model to explain the granary effect, first obtain the functional expression between the falling depth of the isolation layer and the vertical direction compressive stress value P of the highest ore layer, that is, the use The center point data is fitted, and then the compressive stress values of the inclined surfaces are bentonite geosynthetic clay liner manufacturers obtained according to the relationship between the angles.

Take the coordinate grid as the origin, take the horizontal right to the positive direction of the x-axis, and take the vertical bentonite geosynthetic clay liner factory price direction to the positive direction of the y-axis to establish the coordinate system high quality bentonite geosynthetic clay liner. The compressive stress values of the highest ore level at each descending depth are shown in Table 4. The regression analysis is performed on the data in Table 4, and the fitting curve is shown in Fig. 7 (correlation coefficient is 0.995).

Table 3 average tensile stress value of the isolation layer

Table 4: Data of compressive stress values at the highest ore level at each descent depth wholesale bentonite geosynthetic clay liner

Figure 7 is a fitting curve of the relationship between the falling depth and the highest ore surface compressive stress value.

It can be seen from the fitting curve that the compressive stress value of the highest ore surface increases with the decreasing depth of the isolation layer, but the growth rate gradually becomes slower, indicating that in the limited space high quality bentonite geosynthetic clay liner, the moving ore particles and the surrounding rock have frictional effects bentonite geosynthetic clay liner for sale, and the surrounding rock bears Part of the ore weight, while changing its full linear relationship, its fitting function is:

The distribution of compressive stress values on the isolation layer is related to the shape of the isolation layer curve bentonite geosynthetic clay liner factory price. Therefore, the experimental isolation layer evolution curve needs to be analyzed. The morphological evolution curve of the isolation layer is shown in Fig. 8.

It can be seen from Fig. 8 that during the deformation bentonite geosynthetic clay liner manufacturers evolution process of the isolation layer, the overall shape of the isolation layer is a sinusoidal curve, which is continuously evolved to the lower surface of the isolation layer contacting the bottom structure of the funnel. However high quality bentonite geosynthetic clay liner, when the isolation layer contacts the bottom structure of the funnel, its shape changes are complicated, and the curve equation is difficult to express with a unified mathematical model. At the end of the ore release, the shape of the barrier is in the form of a resonant wave. The equation of the isolation layer shape curve is:

Figure 8 isolation layer shaped curve

It can be seen from the formula (15) and in conjunction with FIG. 9 that the isolation bentonite geosynthetic clay liner manufacturers layer corresponding to the cavity portion is not supported by the supporting force, and the variation of the supporting force load of the remaining portion wholesale bentonite geosynthetic clay liner of the isolation layer is consistent with the compressive stress.

It can be seen from equation (11) that in the multi-funnel ore-extraction test under the action of the flexible isolation layer bentonite geosynthetic clay liner for sale, the compressive stress of the isolation layer decreases with the increase of the distance between the measuring point and the center point of the isolation layer before contacting the bottom structure of the funnel; At the end of the process, as the distance between the measuring bentonite geosynthetic clay liner factory price point and the center point of the isolation layer increases, the compressive stress of the isolation layer changes in a similar trend to the sinusoidal function.

(3) Support analysis

The supporting force of the flexible isolating layer in the process of falling with the bentonite geosynthetic clay liner manufacturers ore flow under the ore-mining condition of the multi-funnel isolation layer is the supporting effect from the unreleased ore high quality bentonite geosynthetic clay liner. With the release of the ore, some space parts appear with the isolation layer and The phenomenon of the detachment of the ore surface, the existence of the cavity causes the isolation layer of the space not to be supported by the unreleased ore bentonite geosynthetic clay liner factory price. Therefore, it is necessary to discuss the situation when analyzing the support force of the isolation layer, that is, the isolation layer is not affected separately. The influence of the cavity and the support of the affected part of the cavity are discussed bentonite geosynthetic clay liner for sale. In addition, due to the complexity of the force of the isolation layer contacting the bottom structure of the funnel, only the support force before the separation layer contacts the bottom structure of the funnel is analyzed.

1 In the area of the isolation layer where no bentonite geosynthetic clay liner manufacturers cavity is created, the isolation layer is subjected to the support of the ore at the bottom wholesale bentonite geosynthetic clay liner. Take a micro-seg ds on the isolation layer, according to the micro-segment normal force balance analysis, there are:

Where: B is the width of the isolation layer; t is the thickness of the isolation layer high quality bentonite geosynthetic clay liner; ρ is the radius of curvature of the shape curve of the isolation layer. The function expression of the support force q2 can be solved by the combination of equations (11) and (14):

2 In the area of the isolation layer where the cavity is not generated, the isolation layer is subjected to the support force of the ore which is not released at the bottom bentonite geosynthetic clay liner manufacturers, and thus the supporting force of this part of the isolation layer is zero, as shown in FIG.

Figure 9 isolation layer cavity diagram

It can be seen from FIG. 11 and (20) that the maximum tensile bentonite geosynthetic clay liner manufacturers stress the value of the isolation layer increases exponentially as the falling depth increases as the isolation layer contacts the bottom structure of the funnel. Therefore, in the engineering practice, in order to prevent the failure of the isolation layer bentonite geosynthetic clay liner for sale, the flexible isolation layer material with appropriate strength can be selected according to the relationship between the maximum tensile stress and the falling depth.

(4) Analysis of friction.

During the lowering process of the isolation layer wholesale bentonite geosynthetic clay liner, the upper and lower surfaces are in contact with the section of the isolation layer which is filled with the waste rock and the rock. The frictional direction of the upper surface of the isolation layer is obliquely downward in the section where the slope of the profile curve of the isolation layer is larger than the outer friction angle of the waste rock, and the slope of the profile curve of the isolation layer is obliquely smaller than the section bentonite geosynthetic clay liner factory price of the friction angle of the waste rock. The lower surface of the isolation layer of the cavity section is not subjected to frictional force, and the direction of the frictional force of the isolation layer of the section above the cavity boundary point is obliquely upward high quality bentonite geosynthetic clay liner. Therefore, for the complex stress of the isolation layer, the combined force of the frictional force of the isolation layer during the ore-extraction process is taken as the friction force of the isolation layer, and the total friction force is represented by f3.

A micro-seg ds is taken on the isolation layer for force analysis, as shown in FIG. From the tangential force balance of the micro-segment bentonite geosynthetic clay liner manufacturers, you can get:

Fig.10 Analysis of friction layer micro-section of the isolation layer wholesale bentonite geosynthetic clay liner

Finished up:

Therefore, the functional expression of the frictional force set of the flexible isolation layer is:

It can be seen from equation (18) that before the isolation layer contacts the bottom structure of the funnel bentonite geosynthetic clay liner manufacturers, the changing trend of the frictional force of the isolation layer is consistent with the changing trend of the cosine function.

3. Failure analysis

The strength of the insulation layer is one of the key factors to achieve smooth ore mining. If the insulation layer fails during the ore mining process, it will cause direct contact between the ore and the waste rock, increase the loss and depletion of the ore, and also lose the meaning of simultaneous filling.

The internal forces of the material subjected to the test mainly include tensile stress and compressive stress. The tensile stress is caused by the gradual decrease of the filling and separation layer of the rock and the overlying waste rock and the friction of the filled waste rock and the rock bentonite geosynthetic clay liner for sale. The compressive stress is generated by the self-weight of the overlying waste rock acting directly on the surface of the separator. The failure of the isolation layer is mainly due to the fact that the maximum tensile stress acting on it is greater than the tensile strength of the isolation layer. Since the tensile stress values of the isolation layer are distributed in a sinusoidal function at each depth of decline, the maximum point of the tensile stress inside the isolation layer during the entire ore-out process is the failure point, which satisfies the equation:

In the process of ore-extracting, the relationship between the maximum tensile stress of the insulation wholesale bentonite geosynthetic clay liner layer and the depth of the isolation layer is shown in Fig. 11. The fitting formula is:

Where C is the maximum depth of descent of the barrier layer within this range of descent, 109 cm. It can be seen from the formula (10) that the depth of the drop after the isolation layer contacts the bottom structure is only 8 cm, and most of it is in the area where the bottom structure is not contacted, so only the area of the uncontacted bottom structure is analyzed below. Since the isolation layer is a resonant wave during the decline of the range, and the compressive stress acting on the isolation layer has a certain angular relationship with the compressive stress acting on the highest ore level, the isolation layer can be contacted before the funnel bottom structure and the ore deposit At the end of the isolation layer bentonite geosynthetic clay liner for sale, the compressive stress function q1 is expressed as:

Figure 11: Fitting stress maximum and falling depth fitting curves

4. Conclusion

Based on the synchronous filling and ore physics model, the tensile and compressive strains of the flexible isolation layer in the multi-funnel ore mining experiment were measured. According to the measured data, the tensile stress, compressive stress, supporting force, friction force and failure conditions of the whole process of the mine are analyzed respectively. The analysis results are as follows:

(1) Under the same descending depth, as the distance between the measuring point and the center point of the isolation layer increases, the variation trend of the tensile stress of the isolation layer is consistent with the sine function. When the distance between the measuring point and the center point of the isolation layer is constant, the tensile stress value of the isolation layer increases with the decreasing depth; the internal average tensile stress value increases exponentially with the decreasing depth before the isolation layer contacts the bottom structure. for:

(2) Under the same descending depth, the compressive stress value of the isolation layer decreases as the distance between the measuring point and the center point of the isolation layer increases. When the distance between the measuring point and the center point of the isolation layer is constant bentonite geosynthetic clay liner for sale, the compressive stress value of the isolation layer increases as the falling depth increases.

(3) The isolation layer corresponding to the cavity part is not supported by the supporting force, and the variation of the supporting force load of the other part of the isolation layer is consistent with the compressive stress.

(4) Under the same descending depth, the frictional force value of the isolation layer changes with the cosine function as the distance between the measuring point and the center point of the isolation layer increases. When the distance between the measuring point and the center point of the isolation layer is constant, the friction value of the isolation layer increases as the falling depth increases.

(5) The maximum point of tensile stress inside the isolation layer during the whole process of ore discharge, ie the failure point, satisfies the equation s=±30.12cm; the maximum tensile stress of the isolation layer and the falling depth of the isolation layer satisfy the equation.