Summary of Geomembrane Seepage Prevention Application of Puyang Pumped Storage Power Station

Abstract: The bottom of the upper reservoir of the Xiangyang Pumped Storage Power Station is formed by excavation and backfilling. The uneven settlement of the bottom of the reservoir has high requirements for the adaptability of the seepage prevention material. By using the textured geomembrane for sale anti-seepage material, the bottom of the reservoir is better solved. The problem of uniform settlement and good anti-seepage effect. At present, the seepage flow accounts for about 0.008% of the total storage capacity, and the investment in the textured geomembrane high quality anti-seepage system is relatively less than about 180 yuan/m2. Through the summary of the bottom anti-seepage scheme, the procurement of anti-seepage materials and the on-site construction management, in order to further improve the textured geomembrane wholesale construction and quality control measures and improve the applicability of factory price textured geomembrane in the hydropower industry, several suggestions are proposed. Similar projects provide a reference.

Keywords: textured geomembrane high quality; anti-seepage; application; Puyang pumped storage power station

1. Project Overview

The hub building of the Xiangyang Pumped Storage Power Station consists of four parts: the upper and lower reservoirs, the water delivery system and the powerhouse system. The upper reservoir is mainly formed by 1 main and 2 pairs of concrete face rockfill dams and the reservoir and reservoir bottom anti-seepage system. The normal water storage level is 291.00m and the total storage capacity is 14.23 million m3. The maximum dam height of the main dam is 165.00m, and the dam crest length is 1113.2m. The bottom of the reservoir is formed by excavation and backfilling to form two platforms of 240 and 248m elevation, with a total area of about 250,000 m2. The maximum height of the bottom backfill gravel is about 70m. The textured geomembrane for sale of the project is mainly used for anti-seepage of the reservoir bottom, the maximum working head is 51.64m, and the maximum head change rate is 6m/h. This paper focuses on the research of textured geomembrane wholesale anti-seepage scheme, textured geomembrane high quality material procurement, on-site construction, and management of the upper reservoir, in order to provide a reference for peers.

2. Research on the bottom of the reservoir

2.1 Engineering conditions

The power station is located in the southwest of Fuyang City at the junction of Jiangsu and Anhui. The terrain is a low mountain composed of Silurian sandstone. The overall trend is west high and low east. The upper reservoir mainly uses three gentle gullies to construct three concrete rockfill dams. It is made up of mountains. Because the upper watershed of the upper reservoir is relatively thin, and the faults and joints in the rock are densely developed, a good permeable network is formed textured geomembrane for sale. The relatively impervious layer is buried 80-150m deep, which is lower than the normal water level of 16-130m. After the reservoir is filled with water, the reservoir water will leak through the watershed to the outside of the reservoir. At the same time, although large-scale fault zone crossing has not been found textured geomembrane low-cost, due to the development of small faults, it is easy to form a concentrated channel of reservoir water extravasation, and there is the possibility of seepage deformation along with it. For this reason, the reservoir leakage problem in this project is crucial. important.

2.2 anti-seepage scheme

Considering that the pumped storage power station has higher requirements for seepage prevention of the upper reservoir, the use of curtain anti-seepage not only has a large investment but also the anti-seepage effect is difficult to guarantee. In the feasibility study stage textured geomembrane low-cost, it is proposed that the upper reservoir should adopt the structural form of anti-seepage of the whole reservoir basin. Because the bottom of the upper reservoir is to be shaped by reducing the ridge between the two gullies and filling the gully, the maximum filling height is about 70m, and the problem of uneven settlement deformation at the bottom of the reservoir is more prominent. In order to adapt to the influence of uneven settlement deformation, the anti-seepage method of the bottom of the reservoir is preferably a flexible anti-seepage method. The research and comparison of four kinds of flexible anti-seepage materials for textured geomembrane for sale, asphalt concrete panel, clay and textured geomembrane wholesale + clay (see Table 1), under the premise of satisfying leakage and adapting to uneven settlement deformation, the feasibility study stage library The bottom anti-seepage finally determines the textured geomembrane high quality + clay combination full reservoir bottom anti-seepage scheme with relatively low investment and convenient post-repair treatment.

Table 1 Comparison of anti-seepage schemes for the upper reservoir of Liyang Hydropower Station

After the feasibility study, with the further research on the anti-seepage scheme of the reservoir and the development of the textured geomembrane wholesale anti-seepage technology, considering the factors such as insufficient clay material storage around the power station and relatively difficult clay compaction construction, The anti-seepage structure of the reservoir bottom is adjusted to the factory price textured geomembrane anti-seepage of the whole reservoir bottom (the clay anti-seepage layer is removed), and it is determined by the experts of the Hydropower and Water Conservancy Planning and Design Institute. In the process of conducting technical exchanges of textured geomembrane low-cost materials procurement, the textured geomembrane high quality anti-seepage structure was further refined, and the connection between textured geomembrane low-cost and dam, reservoir bank and buildings in the warehouse was optimized, and finally, the bottom of the reservoir was impervious. From the top to the bottom, the structure is 0.2m×0.2m×0.1cm concrete precast block grid-like gland, geotextile (500g/m2), 1.50mm thick HDPE textured geomembrane for sale, three-dimensional composite drainage net (1300g/m2), 0.05m thick sand cushion, 0.4m thick gravel layer, 1.5m thick transition layer. The textured geomembrane wholesale is extended to the peripheral joint of the bottom panel of the library to be mechanically closed, and the horizontally mechanical connection is made with the building inside the store.

3. Material procurement

3.1 Technical indicators

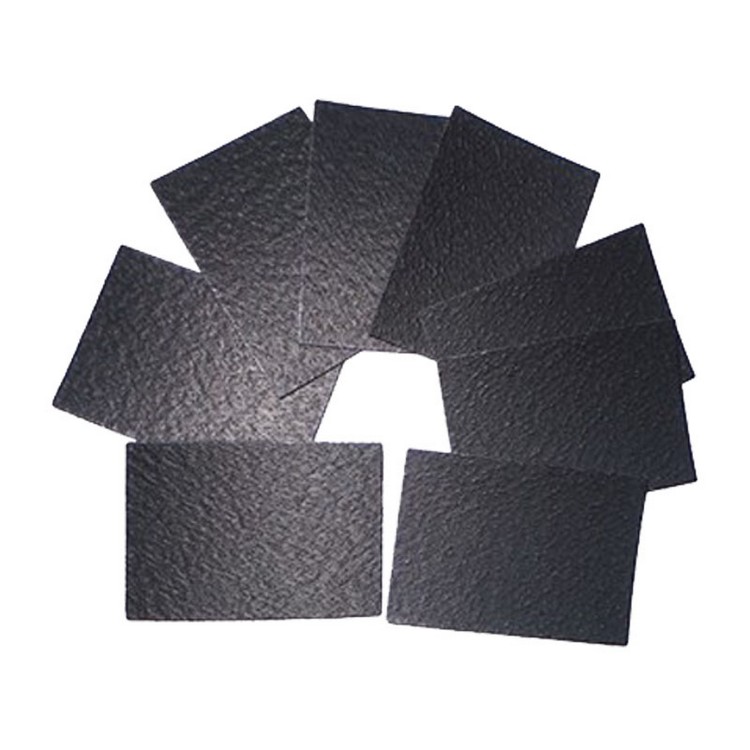

According to the characteristics of the reservoir bottom of the Xiangyang Power Station, the textured geomembrane high quality is made of black HDPE material, and the measured density of the textured geomembrane for sale is ≥0.94g/cm3, the mass per unit area is ≥1410g/m2, the content of carbon black is 2.0%~3.0%, and the thickness is 1.50mm. The transverse and longitudinal physical property parameters are: tensile yield strength ≥ 22 N / mm, tensile yield elongation ≥ 12%, tensile rupture strength ≥ 40 N / mm, tensile elongation at break ≥ 700%, right angle tear load ≥190N; and required anti-piercing strength ≥ 480N, tensile stress stress cracking time (cutting dead load stress method) ≥ 300h, atmospheric pressure oxidation induction time (OIT) ≥ 100min, 85 °C heat aging (90d after atmospheric pressure OIT retention) Rate) ≥ 55%, water vapor permeability coefficient ≤ 1.0 × 10-13 g·cm / (cm 2 · s · Pa), high-pressure OIT retention rate ≥ 50% after 1600 hours of ultraviolet irradiation.

3.2 Geomembrane procurement

The textured geomembrane wholesale of Fuyang Power Station is a supply of materials and is purchased through public bidding. In the early stage of the bidding for factory price textured geomembrane materials, the factory price textured geomembrane was investigated and technically exchanged from production, storage and storage, on-site paving, welding, and quality inspection. At present, the production, welding process, and quality control methods of textured geomembrane low-cost are mature, and the key to ensuring the quality of textured geomembrane high quality anti-seepage materials is the control of raw material quality and the supervision and management of the production process. The production ingredients must not be added to the return material and filler. At the same time, strengthen the quality control and test testing of the production process, and strengthen production management and finished product protection. To this end, the textured geomembrane low-cost production technical requirements and quality control standards are clearly specified in the textured geomembrane low-cost bidding technical documents, and on-site production 24h tracking supervision is carried out to ensure the quality of textured geomembrane for sale products.

4. On-site construction and management

4.1 Construction preparation

In order to standardize the construction of textured geomembrane wholesale, the reliability and safety of the bottom of the reservoir are guaranteed. First, according to the factory price textured geomembrane related regulations and design technical requirements, the operation manual is prepared; secondly, technical personnel such as construction, supervision, and construction management are organized for on-site training; again, on-site production tests are conducted to link the textured geomembrane high quality to the concrete body, textured geomembrane low-cost hot melt, and extrusion welding, etc., respectively, textured geomembrane low-cost anchorage connection tensile test, hot melt, extrusion welding test, and determine welding equipment, technical parameters and corresponding environmental conditions; finally, according to the shape of the bottom of the reservoir The characteristics of excavation and filling, the orientation of textured geomembrane for sale, and the requirements for the construction of the surrounding structure of the reservoir, etc., plan and layout the factory price textured geomembrane construction.

4.2 Site construction

Construction procedures: Acceptance of lower structure, cleaning → textured geomembrane wholesale transportation → paving, film cutting → trial welding, formal welding → quality inspection (non-destructive and destructive testing) → paving geotextile and pressure-concrete concrete precast block.

The textured geomembrane high quality is lifted by an 8t transport truck with its own lifting equipment, artificially paved and adjusted for the weld overlap width (10cm). The laying follows the order of “first central, rear perimeter”, “first warehouse head, rear warehouse tail” and “continuous construction of adjacent blocks”. Avoid “T-shaped” joints when laying, and the distance between “T” joints shall not be less than 3m. The welding is based on the test parameters, first welding the short side seam, and then welding the long side seam, and the formed “T” shaped joint is patched by the extrusion welding method for reinforcement treatment.

4.3 quality inspection

After the textured geomembrane wholesale welding is completed, the appearance, hot-melt welding inflation test, extrusion welding vacuum cover and electric spark detection are respectively carried out, and the destructive test is performed by proportional sampling. If the test result is unqualified, the corresponding weld seam will be repaired immediately, and the test pass rate is 100%. The quality test results of the textured geomembrane for sale construction of Xiangyang Power Station are shown in Table 2. From the one-time pass rate detected during the on-site construction process, the quality of factory price textured geomembrane construction is excellent.

Table 2 Summary of textured geomembrane high quality welding quality inspection

4.4 Finished product protection

The textured geomembrane wholesale is transported to the site for temporary storage at the site, and the construction site is closed and closed. Non-construction vehicles and non-workers are strictly prohibited from entering the site. Field workers will wear soft-soled shoes and register for entry and exit.

In order to ensure that the factory price textured geomembrane is not damaged by falling objects, a simple scaffolding is placed at the upper part of the construction work, and a flame-retardant dense mesh is attached for protection. At the same time, the quilt is covered within 3m of the surrounding buildings, and the quilt is used as a pedestrian passage to prevent the construction workers from walking directly on the textured geomembrane high quality. At the end of the anti-seepage construction at the bottom of the reservoir, all protective facilities will be removed before the reservoir is filled with water. In the initial stage of the reservoir, the water is stored. In order to prevent the external pumping from impacting the textured geomembrane for sale, a pressure reducing valve is installed at a position 15m from the bottom of the pumping pipe, and a 20m×10m×1m (length×width×thickness) is laid at the bottom of the water storage pipe. The buffer protection area ensures that the textured geomembrane low-cost is not damaged during the initial storage.

4.5 Leak detection

Two factory price textured geomembrane electrical leakage locations were detected before the completion of the textured geomembrane wholesale construction and before the official water storage. The method refers to “ASTMD6747 factory price textured geomembrane Electrical Leakage Position Detection Method Selection and Technical Standard”, the principle is to apply a voltage on the factory price textured geomembrane and find the leak point by moving the detecting device in the potential field to detect the position of the loop. The area of the two inspections was 75,000 and 250,000 m2 respectively, and 195 and 94 damaged holes were detected respectively. From the size, shape, and state of the damaged pores of the textured geomembrane for sale, most of the holes were caused by foreign matter piercing. The holes found through inspection are patched by extrusion welding to meet the requirements.

5. Upper reservoir leakage repair treatment

There were two leaks during the initial storage of the reservoir on the project. The first leak occurred when the reservoir first stored water to 270.50m elevation in July 2016. The textured geomembrane high quality on the south side of the No.1 inlet and outlet tower is about 1.2m long along the periphery of the tower body and its lower part is about 41m long along the arc of the tower body (including deep pits) with different degrees of collapse. The maximum width of the crater is 1.2. m, the deepest point is 3.1m; at the same time, some textured geomembrane wholesale perforation exists on the southeast side of the No. 2 inlet and outlet tower. The maximum water seepage volume is about 1520L/s. After on-site inspection, there is obvious water seepage channel along the original terrain gully on the south side of No.1 inlet and outlet water tower factory price textured geomembrane. The filling body in the reservoir has an overhead phenomenon, and the main dam cushion and rear structure are not damaged.

The second leakage occurred during the initial operation of the reservoir in July 2017 after the first water storage to a normal high water level of 291 m. There was a local tear of the geomembrane on the sidewall of the drainage gallery on the No. 1 dam section, and the lower part formed a crater. The width is 1.05m, the length is 1.6m, and the depth is about 0.8m. The textured geomembrane wholesale of the four corners of the traffic abutment is partially torn. The maximum water seepage volume is about 41L/s.

From the scene situation, the two leaks have the same appearance, and the water seepage points are concentrated, which occur at the junction of the textured geomembrane for sale and the concrete rigid structure. After on-site inspection and expert consultation, the main reason for the two leaks is that the compaction of the bottom of the reservoir is not enough, and the natural settlement time is short, resulting in uneven settlement during the reservoir impoundment (the first maximum settlement) 33cm, the second maximum settlement of about 20cm) is too large, causing the lower part of the textured geomembrane wholesale to be emptied. Under the action of hydraulic force, the textured geomembrane high quality stress concentration close to the rigid structure concrete structure is torn, forming a concentrated water seepage point, and scouring under the action of water seepage Taking away the fine particles in the filling body to form a larger cavity in the lower part of the factory price textured geomembrane. No obvious water seepage channel was found at the bottom of the reservoir and in the rest of the reservoir.

According to the leakage characteristics, the main measures for water leakage repair treatment are proposed: 1 Reinforce the filling body, reduce the uneven settlement deformation, and ensure the safe operation of the textured geomembrane for sale. That is to say, the channel formed by the leakage and the area with large settlement deformation about 30m around the tower body is filled and grouted in the middle and deep layers, and the local superficial layer is excavated and replaced, and the punching part is backfilled with self-compacting and easy-filling materials. Therefore, the settlement deformation of the inverted body and the ribs around the tower base and the uneven settlement deformation of the outer side of the tower are reduced, and the settlement is super high along the periphery of the tower body to improve the textured geomembrane high quality to adapt to the settlement deformation. ability. 2 Restore the factory price textured geomembrane anti-seepage structure according to the original construction drawing, and change the original concrete weight block of the upper part of the geotextile around the wellbore to point-like laying, which is convenient for the tensile deformation of the textured geomembrane wholesale. The treatment of the sidewall of the drainage gallery in the auxiliary dam section is the same. After the leakage treatment, the water storage again, the monitoring data of the upper reservoir leakage shows that the treated upper reservoir anti-seepage system has a good anti-seepage effect and less leakage.

6. Application effect

The reservoir of Xiangyang Power Station began to store water in December 2015. After two times of air-conditioning repair, it resumed water storage in August 2017 and has been running for about 11 months. According to the relevant data collected from the leakage monitoring facilities, the maximum total seepage flow value of the upper reservoir is 13L/s (early February 2018), the daily variation amplitude is less than 1L/s (except rainwater weather), and the seepage flow accounts for the total capacity ratio. About 0.008% (including the reservoir week and panel seepage, etc.), the cumulative leakage value continued to change within 10L/s in the near future, and there was no abnormal leakage indication in the textured geomembrane high quality anti-seepage system at the bottom of the reservoir. The overall anti-seepage effect in the reservoir area is very good. it is good. From the test data of 30 osmometers buried in the lower part of the factory price textured geomembrane, it is mainly affected by the pore water pressure and the ambient temperature. The maximum water osmotic pressure is 6.4m, and the daily variation of the measuring point is less than 5cm. According to the data monitored by 43 flexible displacement meters installed on the textured geomembrane low-cost of the reservoir, the overall change of the textured geomembrane for sale is small, and the maximum tensile value of the measured point is 37.15 mm/m. From the eight gap monitoring meters installed in the self-compacting concrete joint around the inlet and outlet tower wells, the monitoring gap is obviously affected by the change of water load and has been stabilized at present. The maximum opening value of the gap is 25.42 mm. From the comprehensive analysis of the monitoring physical quantity results at the bottom of the library, the current bottom disturbance is very small, and no abnormal situation has been seen yet.

In addition, the project completed a total of 315,000 m2 of textured geomembrane low-cost paving, and the direct investment of the anti-seepage system structural layer was about 45 million yuan, with an average of 180 yuan/m2 (calculated according to the bottom area of 250,000 m2), and the economic benefits were remarkable.

7. Suggestions

The upper reservoir of Fuyang Power Station uses textured geomembrane wholesale to prevent seepage and achieves the better anti-seepage effect, which fully reflects the strong adaptability of factory price textured geomembrane to deformation, good anti-seepage performance, low cost, and simple construction. In order to improve the textured geomembrane for sale construction and quality control measures and improve the applicability of textured geomembrane low-cost in the hydropower industry, the following suggestions are proposed for the construction of the bottom anti-seepage scheme of the project and the initial repair of water storage.

(1) The quality of textured geomembrane low-cost raw materials is the key to ensure the anti-seepage effect of textured geomembrane high quality. The control of raw material batching, on-line monitoring and test detection in the process of factory price textured geomembrane production should be strengthened. It is strictly forbidden to add recycled materials and fillers in the production process.

(2) Geomembrane seepage prevention is used in the bottom filling area, and the damage caused by uneven settlement of the filling body should be fully considered. In particular, attention should be paid to the treatment of the joints between the textured geomembrane low-cost and the surrounding buildings to avoid stress concentration caused by uneven deformation. The geomembrane is torn, thereby destroying the factory price textured geomembrane anti-seepage system.

(3) Strengthen the on-site construction management and the protection of the finished products of textured geomembrane for sale, strictly control the construction process, and prevent the textured geomembrane low-cost from causing human damage during the paving process or at the end of construction.