Talking About the Construction Technology of Geomembrane

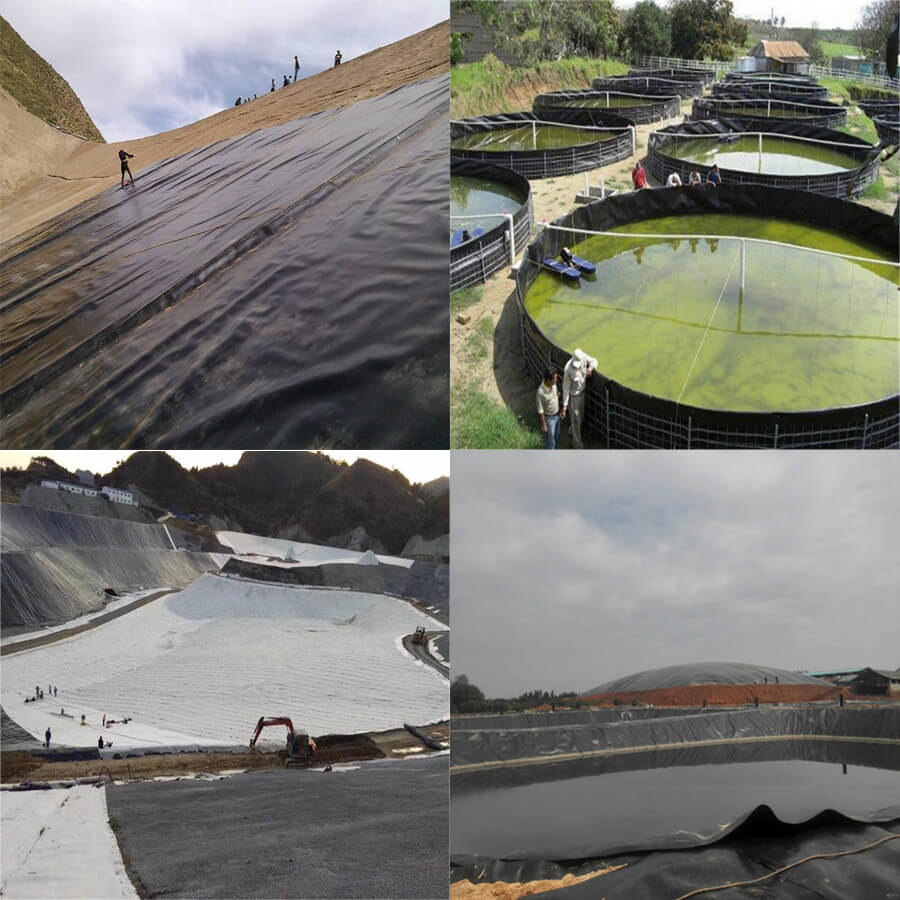

Abstract: Geomembrane is made of plastic film as the anti-seepage substrate, and it is combined with non-woven fabric to form geotechnical anti-seepage material. It is used for various anti-seepage projects such as garbage dump, tailings storage, and dam channel. This paper analyzes and summarizes the construction process and quality control of the two-film composite membrane HDPE geomembrane for sale in the construction of the anti-seepage project of the No. 7 single lake area in the ecological greening irrigation in the southern part of Lanzhou New District, pointing out the possible problems in the construction of HDPE geomembrane manufacturers and Relevant solutions, in order to provide reference for similar water conservancy and hydropower projects.

Keywords: geomembrane; construction technology; quality control; problem; countermeasure

The normal water level elevation of the No. 7 single lake storage project in the southern part of Lanzhou New District is 2003.1m, the dead water level elevation is 1997.5m, the effective volume of the lake is 2,529,200 m3, and the anti-seepage material in the lake area is two-film-membrane composite HDPE geomembrane for sale. filament cloth, PE film, specification 250g/PE0.4mm/250g (900g/m2), the splicing of high quality HDPE geomembrane and geomembrane is mainly by welding method, the bonding of wholesale HDPE Liner made in China and building is mainly bonded by adhesive The total amount of HDPE geomembrane manufacturers engineering is 366,304 m2.

1. Construction plan and process

Before the start of construction, the substrate should be cleaned of impurities, including organic matter and gravel, to avoid damage to the China HDPE liner manufacturers during construction. Then, according to the specific content of the construction design, the laying process should be in accordance with the standard and maintain a certain degree of relaxation in order to withstand greater deformation pressure. After the excavation and excavation, the soil layer should be compacted. Before the construction, the flatness of the earthwork construction should be adjusted to ensure the same amount of material under the membrane.

The geotechnical membrane construction process of this project is: sampling and inspection qualified → cleaning the foundation surface → laying → alignment aligning → pressing film setting → wiping dust → welding experiment → welding → detection → repair → re-examination → acceptance.

2. Precautions for the geomembrane construction process

2.1 Construction plan review

The construction plan is the key to ensure the smooth laying of the HDPE geomembrane manufacturers. Before the construction, it is necessary to analyze the actual situation and relevant data of the project, and repeatedly review the construction plan, from the process flow, mechanical equipment configuration, and personnel arrangement, raw material reserves, quality monitoring, operation specifications. Analyze from multiple angles to ensure that the construction plan and process can be smoothly implemented in this project, and can meet the requirements of anti-seepage quality and reasonable economic input. In addition, before the actual laying of the HDPE geomembrane for sale, the laying test should be carried out at the construction site where the preparatory work is to be carried out, and the construction process parameters such as the welding temperature and the welding speed are confirmed. For hot-melt welding, the equipment should be compared and tested. The test report should be sent to the supervision personnel for approval. Only when the construction process and construction parameters meet the standards can the construction be completed.

2.2 Geomembrane material quality inspection

Under the constraints and guidance of the construction plan, the engineering parameters of the high quality HDPE geomembrane, the quality standards of the materials and the construction specifications, analyze and review the secondary quality inspection results of the construction team and the supervision unit, and identify the standards for sampling quality inspection to ensure China HDPE liner manufacturers materials can meet the quality standards required by engineering. Under normal circumstances, the detection of HDPE geomembrane manufacturers materials should start from the following three aspects.

2.2.1 Written inspection refers to the examination of the material quality certificate and test report and other written materials at the time of material procurement to ensure that the quality of the materials has been identified.

2.2.2 Appearance inspection refers to the quality inspection personnel to test the variety, specifications and external dimensions of China HDPE liner factory price through theoretical knowledge and professional experience to see if there is any quality problem.

2.2.3 Physical and chemical testing Physical and chemical properties are used to detect the physical and chemical properties of wholesale HDPE Liner made in China to ensure that their properties meet the requirements of the project. Although the physical and chemical detection means is critical, the appearance inspection is also very important. For example, unqualified edges, wrinkles, and ruffles are unqualified in appearance quality, which is a key factor affecting the quality of China HDPE liner manufacturers construction.

2.3 Geomembrane support layer, cushion, and protective layer construction

2.3.1 Support layer The high quality HDPE geomembrane support layer is also the base. During the construction process, the base should be cleaned and compacted to ensure that the base is tight and even. If there is a plant root, it should be 5~10cm below the surface. Ensure that the substrate is flat and avoid damage to the HDPE geomembrane for sale due to external factors.

2.3.2 The cushion layer should conform to the construction design during the design process and should not contain any sharp objects to avoid the puncture of the wholesale HDPE Liner made in China and the quality of the project is degraded. The material of the cushion should be carefully inspected, and the debris, roots, gravel, weeds, etc. should be removed to ensure that the sand gravel cushion is flat and there will be no protrusion or depression.

2.3.3 Protective layer After the quality test of China HDPE liner manufacturers construction is passed, the filling of the protective layer shall be carried out. The filling process shall be consistent with the construction speed of the purchase high quality HDPE liner, avoiding the long-term lack of protective layer of the HDPE geomembrane manufacturers and exposure to sunlight. Quality and age have decreased. When the protective layer is filled, equipment and tools that cause damage to the China HDPE liner factory price cannot be used. The mechanical equipment cannot be crushed, and the mechanical construction must be guarded by a person to avoid damage.

2.4 laying and splicing of geomembranes

Geomembrane laying construction should pay attention to weather changes, try to be carried out in a mild, windless, rainless, and no strong sun exposure. During the laying process, it is necessary to check whether the appearance of the film has quality problems in time, and find that holes and other phenomena should be repaired in time. In addition, we should also pay attention to the following problems: First, fireworks are strictly forbidden during the laying process, workers should not wear spikes or hard-soled shoes; second, impurities should be cleaned on the bonding surface before welding to ensure the clean section, after the high quality HDPE geomembrane is laid Timely protection to avoid prolonged exposure; third, due to the possibility of geomembrane deformation, the purchase high quality HDPE liner needs to maintain a certain degree of relaxation.

The purchase high quality HDPE liner joints must be tested before the construction. The China HDPE liner factory price splicing adopts the hot-melt welding method. The connection of the membranes should be tight and moderate, and the membranes should be combined to ensure the joint force. The tensile strength of the joint of the geomembrane is not less than 80% of the base metal. Before the test, the experimental program shall be submitted to the supervisor. After the approval, the test can be carried out. After the test is completed, the test results and reports are submitted to the supervision project for approval, and the construction can be carried out only after approval. It should be operated under the canopy on rainy days to keep the welding surface dry.

2.5 Geomembrane welding quality inspection

The welding quality of high quality HDPE geomembrane is the key to affect the quality of HDPE geomembrane for sale engineering. In the weld quality inspection process, the following three methods are commonly used.

2.5.1 Visually observe the weld directly to see if the joint is flat and even, and there are no welding defects. If there are defects, mark it in time for remediation and treatment. In addition to visual inspection, you can also feel the flatness of the weld by hand to see if there is any defect.

2.5.2 Inflatable detection Seam leak detection There are two kinds of inflation method and vacuum method. Under normal circumstances, the inflation method uses a higher frequency. When leak detection, use the gas needle to insert the middle of the joint, close the pinhole, and then pump it. When the air pressure rises to 0.1 MPa, if the pressure is stable for 30 s, it is considered to be qualified for leak detection. The vacuum (negative pressure) method is a traditional old method, in which soap water is applied to the weld, a vacuum box with five sides is sealed, a vacuum is applied by a vacuum pump, and bubbles are observed under a negative pressure to inspect the holes. Or not strict.

2.5.3 Sampling inspection Indoor testing should randomly select the weld sample on-site for tensile test. If a certain pressure is reached, if the crack is not cracked but is broken elsewhere, the quality is normal; if the weld is broken, this indicates The office is still weak and needs rework remedies.

3. Conclusion

In summary, the China HDPE liner factory price construction process is a complex new technology process, and the HDPE geomembrane for sale composite materials are various. Anti-Seepage construction is a concealed project. In order to ensure construction quality, skill should be established during the construction process. The construction team with high level and a strong sense of responsibility will analyze the problems that may exist during the construction and do a good job of prevention and response. For the project supervision unit, it is necessary to supervise the whole station to avoid the occurrence of China HDPE liner manufacturers construction problems, so as to enhance the effect of the anti-seepage project.