Analysis of Difficulties in HDPE Geomembrane Construction

During the construction process of the HDPE geomembrane, there will be many situations that are easy to ignore or difficult to construct. Faced with these situations, once the construction is dealt with at will or no attention is paid, it will cause hidden dangers to the entire anti-seepage project.

1. Difficulties in the construction of HDPE geomembrane in special parts of the site

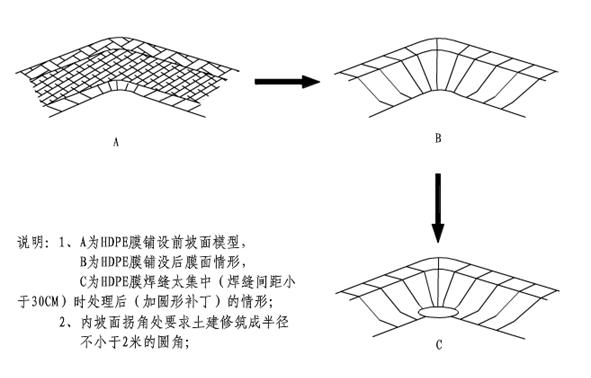

(1) The laying and welding of high quality HDPE geomembrane is a special situation at the intersection of slopes; many anti-seepage projects are caused by improper construction treatment at the intersection of slopes, which causes hidden dangers in the project. Therefore, corresponding measures should be taken according to local conditions In order to make the diaphragm fit more closely with the substrate. The construction points, in this case, are: the diaphragm in the irregular range such as turning should be cut into “upward trapezoid” with upper and lower width, and its width-to-narrow ratio operator calculates accurately according to the actual situation on-site and the specific size of the slope. If the ratio is not accurately grasped, the film surface on the slope will “bump” or “hang”.

Figure 1-Corner treatment of inner slope

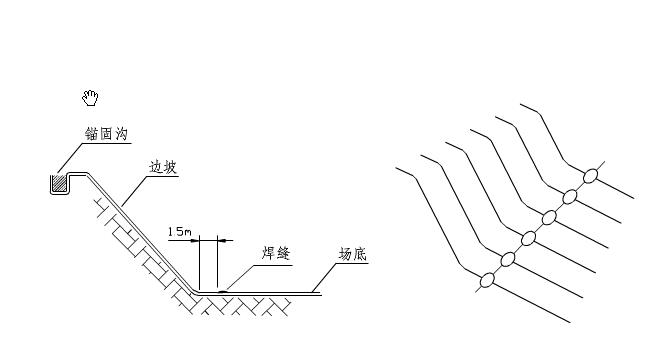

(2) At the foot of the slope where the slope of the channel is connected to the bottom of the field, special treatment is also required. The main points of construction, in this case, are: laying the HDPE film on the slope along the slope surface 1.5m away from the foot of the slope and then welding with the HDPE film at the bottom of the site.

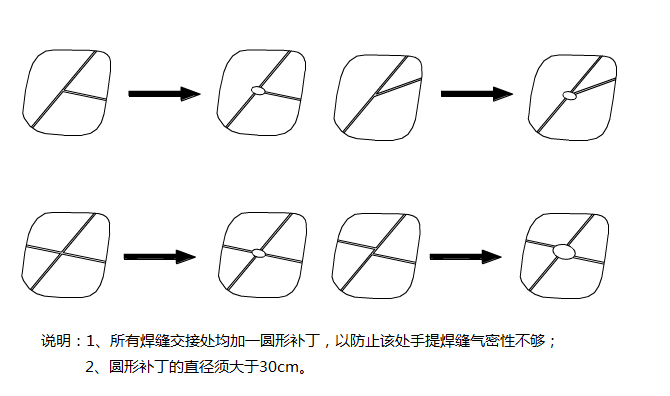

(3) During the entire construction process, the repaired parts after sampling and the places where normal welding construction cannot be used, the construction details tailored to local conditions need to be formulated according to the actual situation of the site, and special techniques are used for construction. Such as “T-type”, “double T-type” and another secondary welding of special welding.

Figure 3-Schematic diagram of welding between multiple films

2. Difficulties of Pipe-through Film Construction

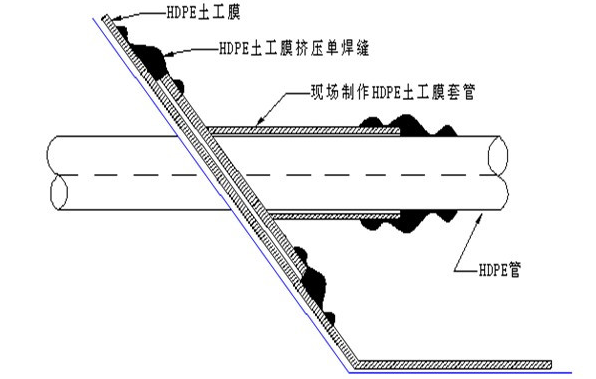

Pipe penetration membrane is a common construction type in anti-seepage engineering. Where the leachate drainage pipe passes through the dam, the pipe and membrane need to be welded to form a special construction process called “pipe penetration membrane”. Often, in many anti-seepage projects, the welding of the pipe through the film is not paid attention to, which saves time and effort, and “glues” the film and the pipe together, laying a hidden danger for the project.

The main points of construction are as follows: first, use HDPE film to make a horn-shaped pipe sleeve, the small radius is the same as the diameter of the pipe through the film, the large radius is about 0.8 meters (the specific size is determined when installing) and divided into 6-8 small pieces, and then Put the pipe sleeve into the dam pipe in order from large to small, adjust the position of the pipe sleeve according to the actual situation on-site and use a hot air gun for temporary stabilization. At this time, pay attention not to allow the pipe sleeve to have a floating part. The large and small sleeves of the casing are welded to the impervious layer HDPE film surface and the pipe, and a stainless steel hoop is added at the HDPE pipe.

Figure 4-Schematic diagram of pipe penetration welding

3. Difficulties in anchoring HDPE geomembrane

HDPE geomembrane anchoring is a vital part of HDPE geomembrane construction. Anchor trenches and buffer platforms will be set in anti-seepage projects to reduce the pull-down force of HDPE geomembrane on the slope and increase stability. For the anchoring of HDPE geomembrane for sale, the following points also need to be noted:

(1) The distance between the anchoring ditch and the slope edge should not be less than 800mm; if the anchoring ditch is too close to the slope, the mechanical structure of the anchoring ditch will likely cause instability in the future use, resulting in a landslide.

(2) When the HDPE geomembrane is anchored, there must be no rigid structure at the corners, all of which are made into arc structure.

(3) When HDPE geomembrane is anchored, care should be taken to allow a certain margin to prepare for sinking and stretching in the future landfill process.

4. The conclusion

In the construction of HDPE geomembrane, it can be said that in addition to using high-quality imported HDPE geomembrane such as Canadian Soma, strict and standardized construction is equally important. Any detail affects the safety and stability of the entire project. Many failed projects are caused by negligence on details that are difficult to construct or easy to ignore. Therefore, a high-quality project must strictly deal with these difficulties and points, and can not cause difficulties or troubles to the construction due to these conditions, and cope with it casually. It is only required to complete the project construction to avoid major hidden dangers for future practical applications.