Discussion on Application of Geomembrane Anti-seepage Technology for Earth-rock Dam

Abstract: With the improvement of China HDPE liner manufacturers production technology and the improvement of technical indexes, the use of composite wholesale HDPE Liner made in China anti-seepage in medium and low earth-rock dams simplify the construction process and saves engineering investment in water conservancy and hydropower projects. The durability, aging resistance, and maintenance of composite China HDPE liner factory price have become the concerns of all parties involved in the construction of engineering, and the application of composite low price China HDPE liner anti-seepage technology has been discussed.

Keywords: composite China HDPE liner manufacturers inclined wall dam body seepage prevention; galvanized flat iron; minimum safety factor for anti-sliding stability; a horizontal inertial force for an earthquake; thrust transfer method

1. Development of geomembrane anti-seepage technology

In 1991, the International Dam Conference published the No. 78 bulletin entitled “Geotechnical Membrane for Dam Water-International Advanced Level”, which clarified that low price China HDPE liner is used for various filling dams such as concrete dams and concrete dams. Is a mature technology. Europe is a pioneer in the application of China HDPE liner manufacturers to dams. In 1993, the European Working Group on wholesale HDPE Liner made in China Geosynthetics specialized in more than 80 dams in Europe and established a database.

China’s low price China HDPE liner seepage prevention technology began in the mid-1960s for channel seepage prevention. Since the 1980s, China HDPE liner factory price began to be applied to the reinforcement of small and medium earth and rock dam projects. From the late 1980s to the early 1990s, some The new small and medium-sized earth-rock dam project began to use low price China HDPE liner anti-seepage. Since the 21st century, more than 10 projects have used composite China HDPE liner manufacturers to prevent seepage. The new maximum dam is 56m, and the dam is 85m high, and the operation is good.

The domestic composite China HDPE liner factory price manufacturers are mainly private enterprises, the production scale is small, the guaranteed rate of product quality is low, and the design unit has insufficient confidence in the quality of materials. Therefore, it is used less in engineering design, and more in some small and medium-sized projects. Used in projects that are difficult to maintain in the middle and later stages. The anti-seepage China HDPE liner manufacturers of the earth-rock dam are usually placed on the upstream dam surface.

2. Anti-seepage design of composite geomembrane inclined wall dam

2.1 Structure of composite geomembrane anti-seepage system

The anti-seepage structure includes an upper cushioning surface of the impervious material, a composite China HDPE liner manufacturers, a supporting layer at the lower portion of the underlying layer, and drainage and exhaust facilities (Fig. 1).

The facing material can be compacted soil, sand gravel, cement mortar, dry block stone, masonry stone, and concrete slab according to the slope ratio of the anti-seepage structure.

The underlying layer support layer may be made of a permeable material such as sand gravel, no sand concrete, asphalt concrete, geotextile, or the like.

The membrane drainage and exhaust facilities can be completed by using a check valve, a drain pipe or a vertical and horizontal drainage blind ditch to form complete drainage and exhaust system.

Fig.1 Anti-seepage structure diagram of composite China HDPE liner factory price for earth-rock dam

2.2 Connection of composite geomembrane sloping wall and anti-seepage curtain

The connection between the composite low price China HDPE liner sloping wall and the anti-seepage curtain grouting is to anchor the China HDPE liner manufacturers to the concrete structure of the heavy toe slab of the curtain grout, forming a space anti-seepage system on the ground floor (Fig. 2). Anchor

Figure 2 Composite wholesale HDPE Liner made in China and toe plate connection diagram

Requirement: Remove the non-woven fabric on the composite China HDPE liner factory price surface of the anchoring surface, the toe surface is smooth and dry, apply asphalt on the concrete surface and low price China HDPE liner surface, and use 3 flat iron crimping on the concrete surface, with a spacing of 30cm, φ16 The stainless steel expansion bolts are fixed with 50mm×100mm galvanized flat iron to press the low price China HDPE liner on the concrete surface. The anchoring width is 60-100cm wide according to the water pressure. The anchoring position can be set on the dam side of the toeboard concrete. Or toe concrete depends on the slope of the dam side.

2.2.1 Anchoring on the side of the dam side of the toeboard concrete

The anchorage section of the composite geomembrane is first anchored and then filled with the dam body. The China HDPE liner manufacturers are easily damaged when filling the dam. The repairing amount is large, the weld seam is large, and the material consumption is large. Therefore, pre-buried wholesale HDPE Liner made in China needs to be protected. When the low price China HDPE liner is anchored by manual trenching and back-to-back toeboard, the manual excavation transition material has a large workload, and the artificial backfilling transition material can only be artificially compacted, and the efficiency is low; the air of the bonding surface cannot be completely Discharge, there is a gas-filled area, and due to the parallel pressure of water pressure, there is a hidden danger of water pressure breakdown wholesale HDPE Liner made in China.

2.2.2 Anchoring on the dam side slope of the toeboard concrete

After the completion of the filling of the dam and the completion of the construction of the supporting layer of the composite China HDPE liner manufacturers, the construction of the composite wholesale HDPE Liner made in China anchoring section is carried out simultaneously with the construction of the China HDPE liner factory price of the dam surface, which is laid from the top to the bottom and anchored on the concrete slope of the toeboard. The air of the knot can be completely discharged and the construction is convenient. The construction quality of the anchoring section can be ensured, and the water pressure is perpendicular to the bonding surface, which is favorable for the bonding surface (Fig. 3).

Figure 3 Composite low price China HDPE liner and toe plate connection diagram

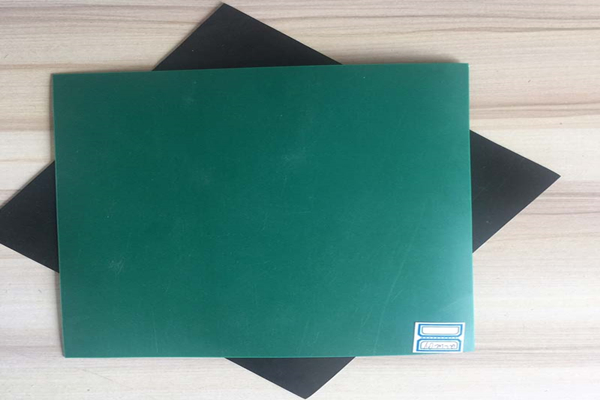

2.3 Selection of composite geomembrane materials

“Technical Specifications for the Application of Geosynthetics” (GB50290-2014) stipulates: “The thickness of low price China HDPE liner for Grade 1 and Grade 2 buildings shall not be less than 0.5 mm, and the high head or important works shall be properly thickened; The thickness should not be less than 0.3mm”.

A composite wholesale HDPE Liner made in China was formed on both sides of the China HDPE liner factory price to form a composite China HDPE liner manufacturers to improve the mechanical properties of the membrane and the performance of the membrane. A polyethylene film (PE) was used.

2.4 Stability analysis of anti-seepage system

The stability analysis of the geomembrane support layer is carried out according to the stability analysis method of the earth-rock dam.

The stability between the composite wholesale HDPE Liner made in China and the support layer and the upper protective surface layer is analyzed by the friction safety factor method:

Where K is the minimum safety factor for anti-sliding stability. According to the grade and operating conditions of earth-rock dams, the values are as specified in 10.3.12 of Code for Design of Rolled Earth and Rock Dams (DL/T5395-2007); f is the friction coefficient of low price China HDPE liner and support layer or a protective surface. The friction coefficient of the composite wholesale HDPE Liner made in China and the gravel support layer is taken as geotechnical β (β is the internal friction angle of the filled gravel). The friction coefficient of composite China HDPE liner manufacturers and the non-sand concrete support layer is f=1~1.5. The friction coefficient of composite soil film and precast concrete panel protection layer is related to the flatness of the bottom surface of the prefabricated plate, generally f=0.4~0.5; When water is present on the composite membrane surface, f = 0.35 to 0.4. f can be determined by field test method; α is the horizontal angle of the slope; tanα is the upstream slope ratio of the earth-rock dam.

The reservoir capacity of Kaimao Reservoir is 22.45 million m3. The reservoir consists of one main dam and five auxiliary dams. The maximum dam height of the auxiliary dam is 25m. The auxiliary dam is filled with limestone material wholesale HDPE Liner made in China. The transition material adopts the old Beichuan channel clearing material and the dam structure. See Figure 4.

Figure 4 sub-dam structure diagram

The mechanical parameters of the stone in the rockfill area are C=40-80 kPa, φ=40°.

The mechanical parameters of the transition layer stone are C=30-60 kPa, φ=38°.

Stability analysis of composite China HDPE liner factory price anti-seepage body of Kaimao Reservoir auxiliary dam under normal operating conditions:

The earth-rock dam level belongs to Class III project, and the minimum safety factor for anti-sliding stability is K=1.3 under normal operating conditions, IK=1.2 for very operating conditions, and IIK=1.15 for every operating condition.

(1) Anti-sliding stability analysis under normal operating conditions.

The support layer adopts the friction coefficient f=1~1.5 when the sand-free concrete and the China HDPE liner manufacturers are used, and the protective surface layer is used to cast the concrete panel protection surface on the composite film, and the part with the minimum frictional force of the contact surface is the contact surface of the sand-free concrete and the transition material or Inside the transition material.

K = 1.3 under normal operating conditions.

Satisfy normal operating conditions, safety factor K ≥ 1.3

(2) Very operating conditions.

As shown in Fig. 5, the transition material and the rockfill C=0, the slip surface is a fold line, the slip surface 1 is distributed inside the transition region wholesale HDPE Liner made in China, and the slip surface 2 is distributed at the rockfill region and the transition material contact surface. The author analyzes the slip surface 1 and analyzes the maximum dam height along the dam axis by 1m length to obtain the slider 1 self-weight W1=3239.46kN/m.

Figure 5 Schematic diagram of the stable calculation of the sliding wedge method

The seismic intensity of the design of the project area is 8 degrees. Check the table 4.3.1 in the Code for Seismic Design of Hydraulic Structures, and obtain αh=0.2g. According to the dynamic distribution coefficient αi of the earth-rock dam of Table 5.1.3, the dam height H ≤ 40 m, design intensity is 8 degrees, α m = 2.5, α i = (αm + 1) / 2 = (2.5 + 1) / 2 = 1.75.

Stability analysis of the particle’s dynamic distribution coefficient αi degree slip surface 1.

Calculation of seismic effects according to the Code for Seismic Design of Hydraulic Structures:

Calculate the representative value of the horizontal to the inertial force of the earthquake wholesale HDPE Liner made in China according to the formula in Article 4.5.9 of the specification:

Qi=αhζGEiαi/g

Where Qi is the representative value of the horizontal inertial force acting on the particle China HDPE liner factory price; αh is the representative value of the seismic acceleration in the horizontal direction; ζ is the effective reduction factor of the seismic action, taking ζ=0.25; GEi is the gravity standard concentrated on the particle Value; αi is the dynamic distribution coefficient of the mass point i; g is the gravitational acceleration.

Q1=αhζGEiαi/g=0.2g×0.25×3239.46×

1.75/g=283.45(kN/m)

According to the “Design Code for Rolled Earth and Rock Dam” DL/T5395-2007 Appendix E.2.2.2 sliding wedge method calculation (Figure 6 is the force diagram of the block):

The anti-sliding force of the soil strip:

Pi=sec(φei-αi+βi)×[Pi-1(φei-αi+βi-1)-(Wi±Vi)sin(φei-αi)+uisecaisinφei△x-ceisecαicosφei△x+Qicos(φei-αi )]

Figure 6 ith block force diagram

Cei=Ci/K, tanφei=tanφi/K

The calculation starts from the first bar at the top (i=1) and calculates P1 according to the above formula China HDPE liner factory price. The thrust force is used to obtain the sliding force Pn=0 of the last bar. The test algorithm is used to repeatedly adjust the K value until Pn=0. This is the calculated value of the K value.

2.5 Geomembrane quality testing method

(1) Visual inspection method: Whether there is any leakage, burns, wrinkles, uniformity, etc. at the site.

(2) On-site inspection method: inflation method and vacuum pumping method.

Inflatable method: used for double-welded film, sealing both ends of the cavity between the double slits, inflating into the cavity, charging to a pressure of 0.05-0.2 MPa, waiting for 0.5 min, if the pressure in the cavity does not decrease qualified.

(3) Vacuum pumping method: Detection is performed by using a suction cup, a vacuum pump, a vacuum machine, or the like. Wipe the joint to be inspected, apply soapy water, put on the suction cup and squeeze it, pump it to a negative pressure of 0.02 ~ 0.03MPa, turn off the air pump, wait for 0.5min, observe the pressure change in the vacuum tank, if there is no change, Indicates the stitching grid.

(4) Laboratory test method.

The China HDPE liner factory price welded at the construction site shall be sampled in the laboratory for shear peeling test. The shear strength shall not be less than 80% of the tensile strength of the parent metal, and the fracture of the specimen shall not appear at the joint.

3. Conclusion

With the improvement of the quality of composite low price China HDPE liner production, the specification of product market, and the improvement of technical specifications, composite China HDPE liner factory price has been developed for a large degree in anti-seepage in hydraulic structures such as medium and low earth-rock dams.