Application of Geogrid Reinforcement in Expressway Subgrade

Abstract: The mechanical characteristics of wholesale polyester geogrid and its reinforcement mechanism for subgrade are analyzed. The main construction techniques and technical points of roadbed reinforcement for wholesale fiberglass geogrid are summarized in combination with engineering experience, and the construction quality control measures in the uniaxial plastic geogrid manufacturers reinforcement process are proposed. The relevant experience summary can provide a reference for fiberglass geogrid factory price reinforcement for uneven settlement of highway subgrade.

Keywords: expressway; subgrade; reinforcement; biaxial geogrid factory price; application analysis

1. Introduction

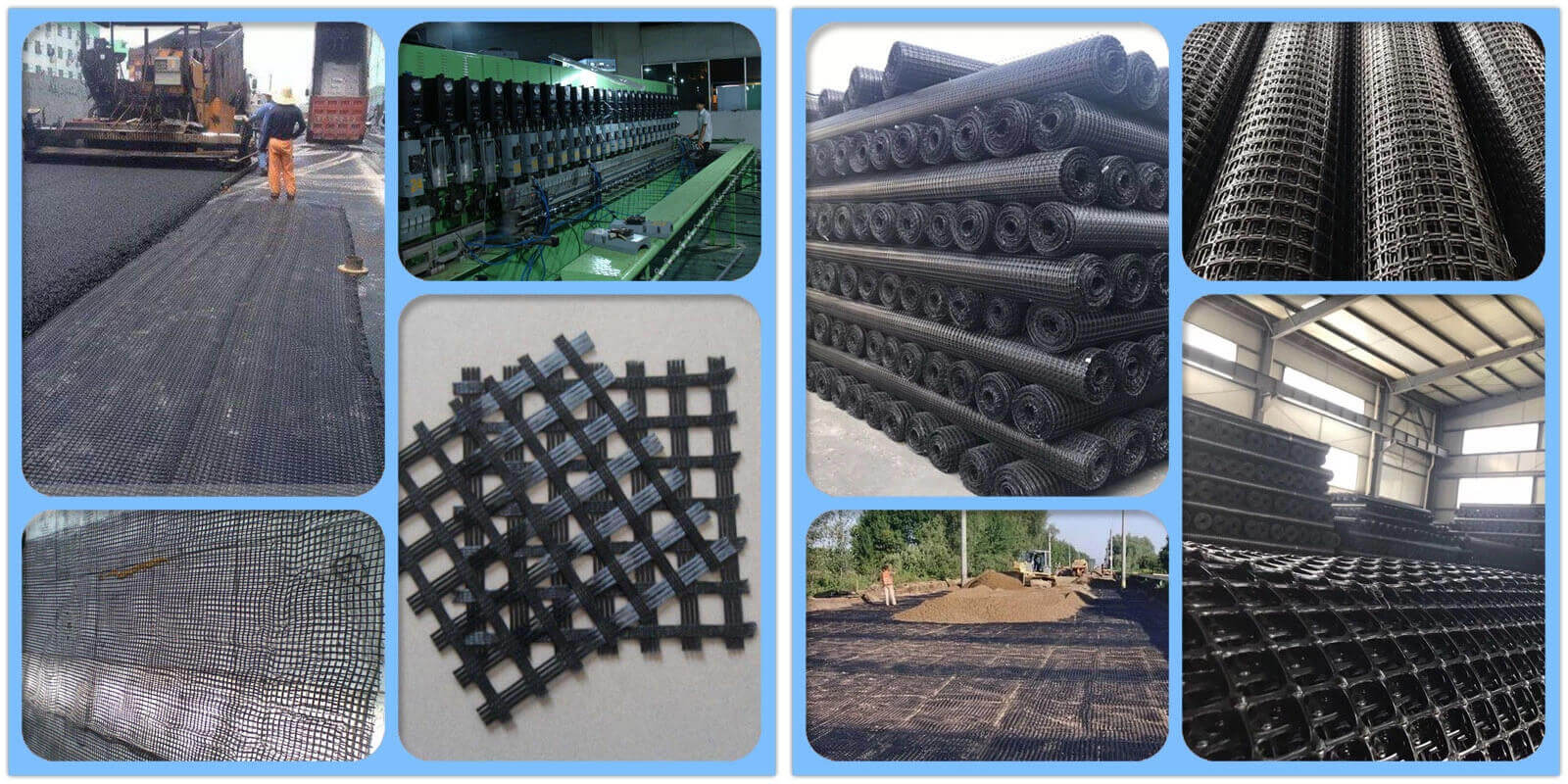

China’s transportation industry has developed rapidly in the past decade, and the traffic operation environment has undergone great changes. Many road subgrades and pavements have different degrees of damage and disease, which greatly reduces the long-term performance of the road. It has a certain impact on driving safety. The obvious problem of the roadbed is the settlement deformation polyester geogrid factory price. The occurrence of settlement not only affects the stability of the slope but also causes great damage to the smoothness of the road surface. Therefore, it is necessary to fill and control the characteristics of the filling material and improve the construction. Construction process detection and other means to ensure its settlement stability [1]. However, due to the complicated process control of subgrade construction and the random effect of human factors, it is difficult to completely control the settlement deformation of the subgrade. It is necessary to use new materials and new processes to improve the safety reserve of subgrade settlement. wholesale polyester geogrid is a geosynthetic material with high strength, low elongation, high abrasion, good toughness, corrosion resistance, and long service life. It makes full use of the strength and deformation characteristics of high molecular polymers to strengthen highway subgrade and prevent it. Settlement deformation has a good effect [2,3]. Combining with engineering experience, the paper discusses the application of uniaxial plastic geogrid manufacturers reinforcement in highway subgrade. By analyzing the mechanical characteristics of biaxial geogrid factory price and the roadbed reinforcement mechanism, the construction technology and technical points of wholesale biaxial geogrid are combed, and the construction quality of wholesale fiberglass geogrid reinforcement is proposed. Control method to promote the application of this technology in highway subgrade construction.

2. Mechanical characteristics of geogrid and roadbed reinforcement mechanism

2.1 Mechanical characteristics of geogrid

The wholesale polyester geogrid is a two-dimensional or three-dimensional grid screen formed by heating, molding, molding, etc. of a polymer material such as polyvinyl chloride or polypropylene (see Fig. 1), and has plastic according to different materials. , glass fiber, steel plastic, glass fiber polyester, and other types, of which plastic biaxial geogrid factory price production process is simple and widely used. The plastic wholesale fiberglass geogrid is formed by stretching to form a polymer mesh material and has two processes of uniaxial stretching and biaxial stretching according to the stretching direction, and the mechanical properties of the uniaxial plastic geogrid manufacturers formed by the two processes are largely different.

The unidirectional tension of the wholesale polyester geogrid is drawn along the length of the polymer. The uniaxial stretching can significantly increase the tensile strength and tensile modulus of the grid, so it can resist the tensile effect and achieve the purpose of reinforcement. Biaxial stretching is simultaneous stretching along the length and width of the polymer, which makes the fiberglass geogrid factory price form a chain system, which plays a good role in the surface load and its diffusion. The uniaxial plastic geogrid manufacturers are heated before stretching, and the polymer is aligned by heat to increase the bearing capacity and strength. In addition, anti-aging materials such as carbon black can be incorporated into the wholesale fiberglass geogrid to improve the acid resistance, alkali resistance, aging resistance and corrosion resistance of the biaxial geogrid factory price. This makes wholesale biaxial geogrid a good application for reinforcement of underground structures and foundation soils with complex operating environments.

Figure 1 Geogrid structure diagram

2.2 Roadbed reinforcement mechanism of geogrid

In order to avoid the settlement deformation of the roadbed, the wholesale polyester geogrid often has vertical and horizontal continuous grid layers at different heights in the subgrade, and the reinforcement mechanism is summarized as follows.

(1) The uniaxial plastic geogrid manufacturers have a large out-of-plane stiffness, which is attributed to the large tensile modulus of the polymer material and its heating and stretching process. Therefore, the biaxial geogrid factory price can spread the road vehicle load and the overburden load to the entire roadbed layer, reducing the local stress concentration problem, thus reducing the occurrence of uneven settlement and improving the bearing capacity of the foundation.

(2) The tensile strength of the wholesale polyester geogrid is large, which increases the stability of the embankment. The strong tensile properties of the fiberglass geogrid factory price make the stability of the subgrade under the sudden and concentrated load better, and the plastic failure is transformed into ductile failure.

(3) wholesale fiberglass geogrid and sand gravel together form a layer of soil with different stiffness to the filling layer, which not only improves the stability of the embankment but also discharges the rainwater in the embankment in time, making the deformation of the foundation more uniform and different. The settlement becomes smaller.

(4) The mesh of the uniaxial plastic geogrid manufacturers are bound by the soil particles filled in it, forming a good interlocking effect. The mechanical occlusion makes the soil layer have good overall shear resistance.

3. Construction technology and technology of geogrid reinforcement

3.1 substrate treatment

Before the construction, it is necessary to clean the substrate, mainly to remove the surface humus soil, and to ensure that there are no gravel or stone in the base layer that affects the working effect of the wholesale polyester geogrid. The cleaned substrate should ensure a certain degree of flatness as much as possible to avoid the occurrence of significant unevenness affecting the reinforcement effect of the biaxial geogrid factory price.

3.2 laying of geogrid

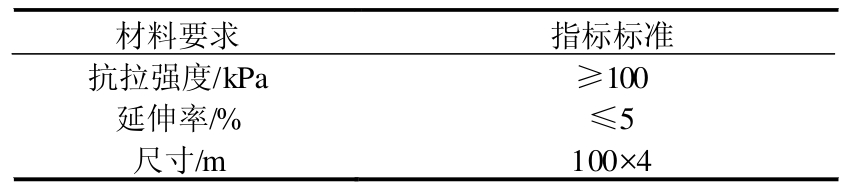

Before the laying of the uniaxial plastic geogrid manufacturers, it is necessary to check whether the design of the fiberglass geogrid factory price meets the requirements of construction reinforcement, and mainly check the properties of the tensile strength, elongation, and size, and generally meet the requirements shown in Table 1.

The laying of the wholesale fiberglass geogrid needs to meet the following requirements:

(1) The storage and laying of wholesale polyester geogrid should avoid excessive exposure for a long time, so as to avoid the performance being deteriorated by the effects of sunlight and humidity;

(2) The biaxial geogrid factory price should be laid perpendicular to the direction of the line to maximize its reinforcement. The lap joint of the grid should meet the requirements of the design drawings and ensure the firmness of the joint, ensuring that the strength of the joint in the direction of the force is not lower than that of the material. Design tensile strength and the stacking length is not less than 200mm;

(3) The strength of the grid joint of the uniaxial plastic geogrid manufacturers is not less than 80% of the tensile strength. In order to ensure that the fiberglass geogrid factory price is not damaged by the filler, it should be ensured that the particle size of the filler within 80 mm of the upper and lower layers in contact with the wholesale fiberglass geogrid is not more than 60 mm;

(4) The continuity of the biaxial geogrid factory price should be maintained during construction, and there should be no problems such as distortion, overlap, and wrinkles. Pay attention to keeping the grille tight and tight, so that the grille is evenly and smoothly attached to the soil layer, and the bolt is used. fixed;

(5) During the laying of the wholesale polyester geogrid, the direction of the long hole should be consistent with the direction of the cross-section, and the straightening grille should be flattened.

3.3 Filling the soil

After the biaxial geogrid factory price is paved, the roadbed filling should be filled in time, and the interval should not exceed 48h. The purpose is to avoid the performance degradation of the grille due to sunlight. The principle of filling the ground is to carry out the symmetrical construction with the principle of the two sides and the middle. This is because if the middle part of the roadbed is laid first and then the two sides are constructed, the connection between the uniaxial plastic geogrid manufacturers and the fill is poor and the fiberglass geogrid factory price is easily destroyed. The packing should be unloaded on the already paved soil surface, and the unloading height should not exceed 1m. It is strictly forbidden to directly unload on the wholesale fiberglass geogrid because the impact effect of the unloading process is likely to damage the paved wholesale biaxial geogrid structure. In addition, all kinds of machinery in the filling construction can not directly walk on the laid wholesale biaxial geogrid but should travel in the direction of the embankment.

3.4 Rolling of geogrid

After the first floor paved fiberglass geogrid factory price reaches a predetermined thickness and is crushed to meet the design compaction standard, the grille can be rolled back to the package 2m, tied to the subsequent wholesale fiberglass geogrid layer, and the rolled area is Trim the anchor, set the earth protection grille, and prevent vandalism. Through the above construction process, the paving process of a layer of wholesale biaxial geogrid is completed.

Table 1 Material requirements for geogrid for roadbed reinforcement

4. Construction quality control of geogrid reinforcement

In order to give full play to the effect of wholesale polyester geogrid on the roadbed reinforcement, it is necessary to carry out quality control on the key processes in the construction to ensure the construction quality and achieve the purpose of fiberglass geogrid factory price reinforcement.

(1) The biaxial geogrid factory price should be subjected to the corresponding material performance test analysis. The test indicators should meet the relevant requirements of the national standard Geosynthetics wholesale biaxial geogrid (GBT17689-2008) and design drawings.

(2) Before laying the uniaxial plastic geogrid manufacturers, pay special attention to the removal of the substrate impurities. In particular, it is strictly forbidden to have hard materials such as gravel and block stones in the surface layer to ensure that the particle size of the roadbed filler within 80mm does not exceed 60mm so that the polyester geogrid factory price is not damaged.

(3) The laying direction of the fiberglass geogrid factory price should be along the direction of the force so that the reinforcement effect can be maximized. Ensure that the paving is smooth, and the polyester geogrid factory price needs to be tightened after the filling is completed and before the rolling construction, so that the grid is under stress and evenly and even close to the lower bearing layer.

(4) The vertical and horizontal directions of the wholesale fiberglass geogrid need to meet the lap length, and the lap joint is dense and firm so that the grid layer is well integrated. Generally, the longitudinal lap length is not less than 500 mm, and the horizontal lap length is not less than 300 mm. The wholesale biaxial geogrid should be laid in the entire cross-section of the roadbed without interruption.

(5) It should be avoided to drive the vehicle on the fiberglass geogrid factory price that has been stretched and positioned, nor can it directly unload the soil on the polyester geogrid factory price. It is found that there are any problems of damage, aging, and pollution in the construction process of the wholesale biaxial geogrid. Replace it in time and do not continue to use it.

(6) The polyester geogrid factory price filling can be evenly distributed by forklifts and excavators and leveled by bulldozers. Subgrade compaction should ensure that the polyester geogrid factory price does not leak, and the rolling requirements are consistent with the subgrade construction requirements. For the filling materials, the water content should be tested in advance to avoid the problem that the polyester geogrid factory price is damaged if the water content is too large after the completion of the construction, and the compaction degree does not meet the requirements.

5. Conclusion

With the improvement of China’s infrastructure construction level and the improvement of people’s quality of life polyester geogrid factory price, the operational requirements and quality of infrastructure are also increasing. Road engineering is the main structure to ensure transportation, but its settlement deformation has always been the key to its service life. Making full use of the advantages of high strength, good rigidity, aging resistance and corrosion resistance of wholesale biaxial geogrid can significantly improve the overall strength and rigidity of the subgrade and reduce uneven settlement deformation. The paper analyzes the mechanical characteristics of the polyester geogrid factory price and its reinforcement mechanism for the subgrade. It summarizes the construction technology and key technologies of the polyester geogrid factory price roadbed reinforcement and sorts out some quality control problems of the reinforcement process to ensure the wholesale biaxial geogrid. The reinforcement effect of the roadbed promotes the long-life use of the road structure.