How Does HDPE Geomembrane Delay Aging

The measures to delay the aging of HDPE geomembrane can be viewed from two aspects: on the one hand, the anti-aging agent is added to the raw materials, mainly to inhibit the effects of external factors such as light and hot river oxidation on the material. If you participate in antioxidants, light stabilizers, and black carbon black. Can delay the service life of HDPE textured geomembrane for sale. On the other hand, take protective measures in the project to minimize HDPE geomembrane materials exposed to the sun and other protective measures.

Geotextile, also known as geotextile, is a permeable geosynthetic material made of synthetic fibers by needle punching or weaving. The finished product is cloth-like, generally 4-6 meters wide and 50-100 meters long. Geotextile is divided into woven geotextile and non-woven geotextile. Geotextile has good filtering, drainage, isolation, reinforcement, permeability, and protection. Features: lightweight, high tensile strength, good permeability, high-temperature resistance, freezing resistance, aging resistance, and corrosion resistance.

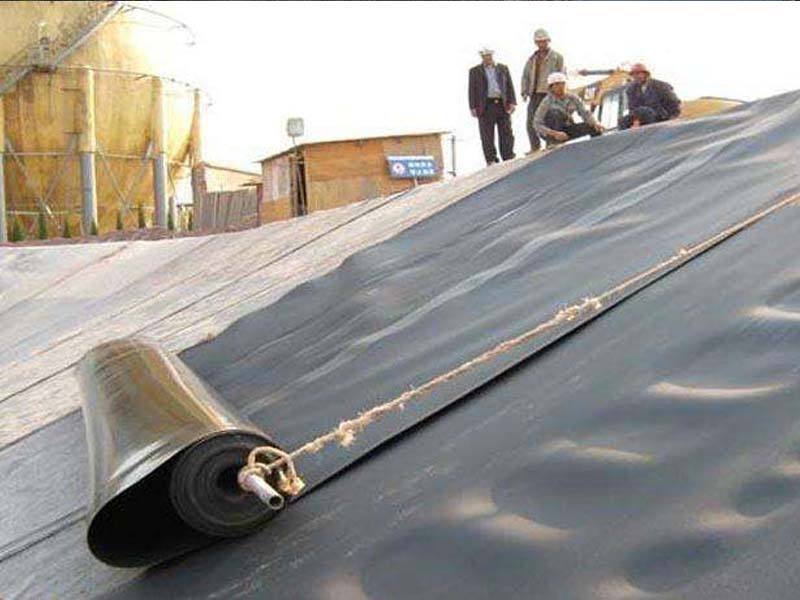

Geomembrane construction site geomembrane uses plastic film as an impermeable base material, and a non-woven fabric composite LDPE geomembrane for sale material, its impermeability depends mainly on the impermeability of the plastic film. At present, the plastic films used for anti-seepage applications mainly include polyvinyl chloride (PVC), polyethylene (PE), and EVA (ethylene/vinyl acetate copolymer). They are a kind of polymer chemically flexible materials with a small specific gravity and extensibility. Strong, high adaptability to deformation, corrosion resistance, low-temperature resistance, good frost resistance.

The main mechanism is the impermeability of plastic film to block the leakage path of the earth dam, which has tensile strength and elongation to withstand the water pressure and adapt to the deformation of the dam body; while the non-woven fabric is a polymer short fiber chemical material, which is needle-punched Or hot-adhesive forming, which has good tensile strength and extensibility. When combined with plastic film, it not only enhances the tensile strength and puncture resistance of the plastic film but also has a contact surface due to the rough surface of the non-woven fabric. The friction coefficient is conducive to the stability of the composite wholesale LDPE geomembrane and protective layer. At the same time, they have good corrosion resistance to bacteria and chemical action, not afraid of acid, alkali, salt corrosion.

1. The seam treatment of the geomembrane is the key procedure of the construction, which directly affects the operating life of the project. According to quality inspection, the hot welding method is ideal. (It can also be bonded by special glue.) The heat welding method is the surface heat treatment of the PE geomembrane produced by environmental geomembrane manufacturers, which melts the surface, and then fuses it into one by pressure.

2. The geomembrane is best laid in a certain direction, and a certain amount of PE film and PET non-adhesive layer is reserved on both sides of the geomembrane. When laying, the geomembrane direction of each unit should be adjusted to facilitate the welding of the aquaculture geomembrane manufacturers of the two units.

3. After the geomembrane is laid, it should be pressed with sandbags to prevent wind, and the edge joints must be free of dirt, moisture, dust, etc.

4. Before welding, adjust the two sides of the PE single film at the seam so that it overlaps certain broadband, and it is flat and free of wrinkles.

5. When welding, technicians with certain experience welding, welding using a special welding machine. To adjust the temperature and speed, (also can be glued).

According to years of practice, the thickness of the low price aquaculture geomembrane is not less than 0.25mm. If it is too thin, it may produce pores, and it is easy to be damaged during construction to reduce the anti-seepage effect. In the construction of geomembrane, special attention should be paid to ensure that the laying is not too tight, wrinkled, and the splicing should be firm. The construction shall be strictly in accordance with the technical specifications, and the quality of preparation, laying, splicing, inspection, and backfilling shall be controlled.