Analysis of Force and Deformation of Flexible Retaining Wall in Road Shoulder Geocell

Abstract: In order to study the stress and deformation characteristics of the flexible retaining wall of the shoulder-type gravel geocell factory price, the model test and on-site monitoring were carried out based on the reconstruction project of the sub-section of Zichang County in the Provincial Highway No. 205 of Shaanxi Province. The model test refers to the engineering prototype material to determine the similarity ratio of the test model is 1:3. The geometric parameters of the retaining wall model are wall height 2m, wall thickness 1m, and slope ratio 1:0.5. Through the model test and on-site monitoring, the variation law of low pressure, horizontal earth pressure and horizontal deformation of the rigid retaining wall of the shoulder-type gravel geocell manufacturers is obtained. The base pressure of the shoulder-type flexible retaining wall increases with the increase of the filling height of the retaining wall, and decreases slightly after the completion of the construction; the horizontal earth pressure on the wall of each retaining wall is not evenly distributed, and the horizontal earth pressure in the middle of the retaining wall > Horizontal earth pressure inside the retaining wall> Horizontal earth pressure outside the retaining wall; horizontal earth pressure and horizontal deformation after stabilization are drum-shaped along the height of the retaining wall, reaching the maximum at 1/2H of the wall height; calculating the retaining wall by differential element method The horizontal earth pressure on the back of the wall is closer to the actual project.

Keywords: road shoulder; high quality gravel geocell flexible retaining wall; on-site monitoring; model test

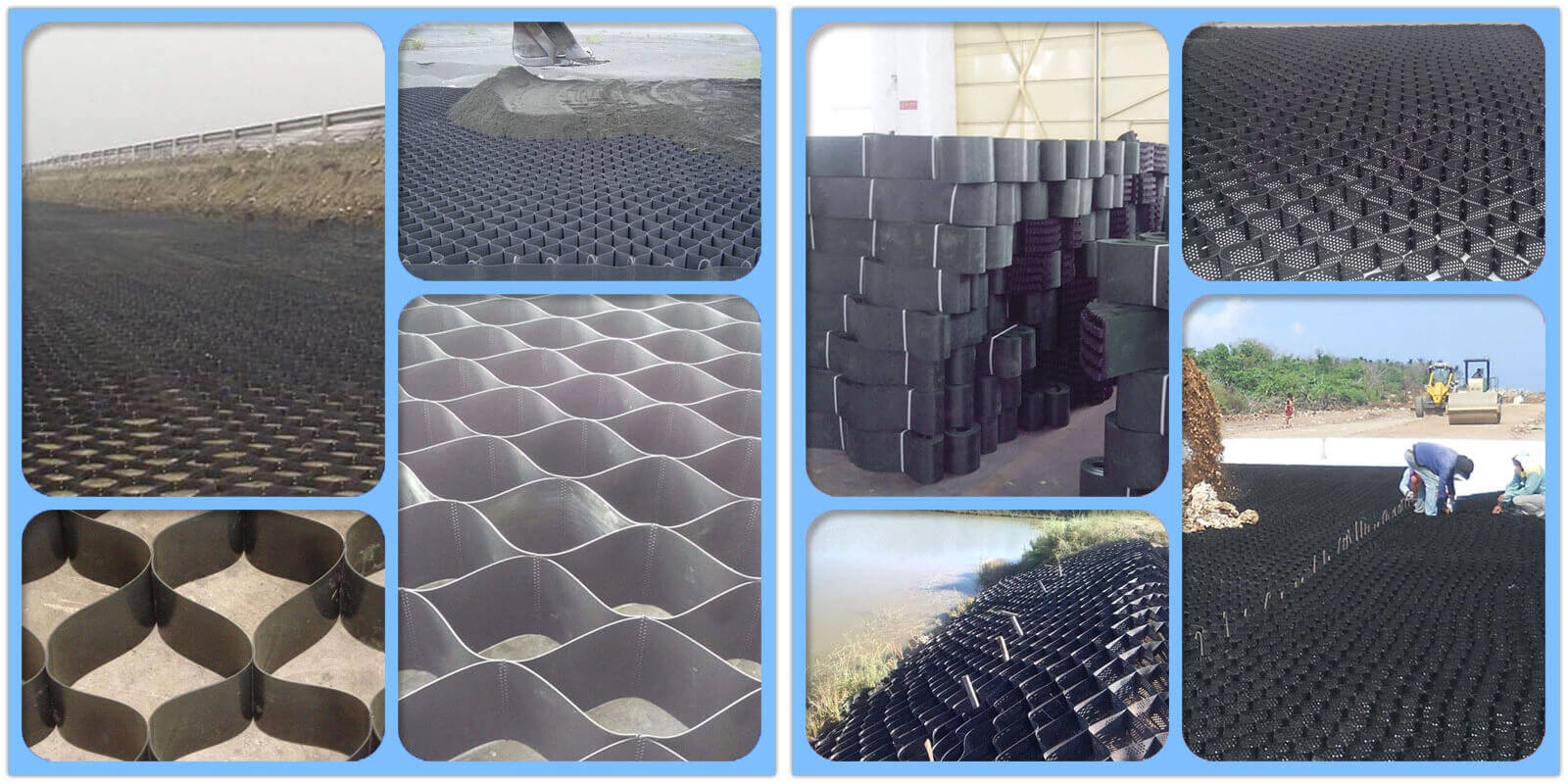

The gravel geocell for sale flexible retaining wall is a composite retaining structure composed of soil and compartment. The structural layer composed of gravel geocell factory price, baffle and filling material is inclined according to a certain gradient (generally 1:0.5~1:0.25). The layers are superimposed, which can reduce the cost of the stone masonry retaining wall by 15% to 30%, and has the characteristics of beautiful appearance, low cost, and good structural stability. Therefore, it has been unanimously recognized and widely used by the geotechnical community and has achieved good economic and social benefits. The gravel geocell manufacturers were born in the early 1980s and were first developed by the Road and Bridge Laboratory of the French Road and Bridge College. At the end of the 20th century, the construction of roads and railways began to adopt geogrid flexible retaining walls. In recent years, the Geotechnical and Tunnel Research Group of the Highway College of Chang’an University has conducted in-depth research and achieved certain results. XIE et al. studied the force and deformation characteristics of the gravel geocell for sale flexible retaining wall by studying the 12m high embankment high quality gravel geocell flexible retaining wall. Yan Changgen et al proposed to control the problem of excessive local deformation of the retaining wall by laying the reinforced layer. Qu Dianhui et al. proposed using the slice unit method and the differential element method to calculate the horizontal earth pressure of the gravel geocell manufacturers flexible retaining wall. However, the application time of gravel geocell for sale flexible retaining wall is still short in China. There are still many shortcomings in design and construction theory. The related research on the force distribution and deformation distribution of retaining wall mainly relies on a small number of on-site monitoring and numerical simulation. In this paper, combined with field test and model test, the force and deformation behavior of 6m high shoulder-type high quality gravel geocell flexible retaining wall are discussed.

1. Project Overview

1.1 Project Introduction

The model test and on-site monitoring rely on the reconstruction project of the sub-section of Zichang County in the Provincial Highway No. 205 of Shaanxi Province. The K11+850~K11+880 section of the expressway is located at the mouth of Chenjiawan, and a tunnel is connected to the west section. The terrain fluctuations vary greatly. There are farmland and residential houses in front of which can not be used for grading treatment. The slope protection is carried out by the shoulder-type gravel geocell factory price flexible retaining wall scheme. The retaining wall is 30m long, 6m high and the slope rate is 1:0.5.

The main measuring section and the auxiliary measuring section are arranged on the wall of the ecological flexible retaining wall of the high quality gravel geocell, and the horizontal earth pressure and the base soil pressure of the retaining wall are measured by 30 steel string earth pressure boxes, and the bottom pressure box is used. Horizontally embedded, the force surface faces the retaining wall soil, and the earth pressure of the retaining wall is measured. The rest of the pressure box is embedded laterally, and the pressure box is facing the soil behind the wall, and the horizontal earth pressure of the retaining wall is measured.

The horizontal deformation of the retaining wall is observed by a flexible displacement meter, which is embedded in the first, sixth, 12th, 18th, 24th and 30th floor cells, and 12 flexible displacement meters are buried. The component arrangement is shown in Figure 1.

1.2 Engineering geological conditions

According to the survey data, the terrain of the K11+850~K11+880 section of the expressway varies greatly. The current situation is a deserted terraced land. The ground is widely covered with Malan loess and aeolian sand, and the thickness is about 5~8m. The underlying bedrock is a strongly weathered and moderately weathered siltstone. The bedrock has a shallow depth, and the local tectonic development geological section is shown in Fig. 2.

2. Model test plan design

2.1 Determination of similarity ratio

According to the similarity theorem, the structural model under the three-dimensional stress state should be kept strictly similar to the geometrical dimensions of the prototype structure, considering that the thickness of the material used in the engineering gravel geocell factory price is only 1.2 mm (when the cell material is less than 0.4 mm, The welding of the cells themselves and the connection between the cells will become very difficult. In this paper, the model test similarity ratio is set to 1:3.

This model test mainly considers the relationship between load and deformation. Therefore, the model test mainly considers the following related physical quantities: load F, geometric length L, stress σ, bulk density γ, material elastic modulus E, Poisson’s ratio μ, strain. ξ, line displacement ω and angle φ. In the model test, the dimension of Poisson’s ratio μ, strain ξ, and angle φ is 0, which is called dimensionless quantity, and its similarity ratio is generally 1. Therefore, the similarity ratio between the prototype and the model is represented by C below, and the length and force are selected as two basic dimensions, and the similarity criterion is derived for the remaining physical quantities.

2.2 Selection of similar materials

The cell material used in the engineering prototype is a high-density polyethylene material, and the results are derived according to the previous similarity theorem, CE=CLCγ, generally Cγ≈1. Therefore, CE = CL, the modulus of elasticity of the prototype material should be three times that of the model material. In actual engineering, it is required that the high quality gravel geocell material is deformed by 5% as the maximum allowable deformation variable, and the strength corresponding to the deformation amount is used as the ultimate strength under normal use conditions. For the gravel geocell for sale used in the field, the ultimate strength of the 5% deformation was measured. A sample of 10 cm in length, 4 cm in width and 1.2 mm in thickness was selected on the gravel geocell factory price sheet for tensile test. The test results were The maximum external resistance is 781N and the tensile strength is 13.01MPa. The theoretical thickness of the sheet in the model is 0.4 mm. The model material was screened several times, and the actual thickness of the final selected sheet was 0.4 mm. A sample with a length of 10 cm and a width of 4 cm was also selected on the model material for the tensile test. The test result is that the resistance to external forces is 291 N, which is 89.4% of the actual theoretical value. The test curve of the tensile force and deformation of the model and the prototype gravel geocell manufacturers sheet is shown in Fig. 3.

In combination with the actual project, there are two kinds of soil samples for the retaining wall filler in this model test: sand and actual loess used in the project. Because the sand grading is relatively simple, it is not sensitive to compaction, which is helpful to highlight the main contradiction in the test analysis and weaken the impact on the test due to the difference in compaction and manufacturing process. Therefore, the test uses fine sand with similar bulk density, and its physical and mechanical indexes are measured through a series of indoor geotechnical experiments, as shown in Table 1 and Figure 4, respectively.

2.3 Physical model size

According to the test requirements, the test parameters of the three-dimensional similar retaining wall model are wall height 2m, wall thickness 1m, slope ratio 1:0.5, and the appearance of the model is shown in Figure 4 and Figure 5.

2.4 Layout of monitoring components

The structural models used in the model tests tend to be relatively small, so the model tests have high requirements for the size and accuracy of the test instruments. In this model test, the earth pressure was tested using a miniature strain gauge earth pressure box of the type YSV3211. The horizontal deformation of the retaining wall is tested by a flexible displacement meter of type HYDG. The two points of the displacement gauge are connected by flexible steel wires, and the two ends are fixed on the gravel geocell factory price to be measured, and the horizontal deformation of the material is measured. A total of 30 microstrain gauge pressure boxes and 12 flexible displacement meters were used in this model test, and the specific layout is shown in Fig. 6.

3. Test results and analysis

3.1 Subsoil pressure

The earth pressure of the geotextile flexible retaining wall increases with the increase of the filling height, showing a non-linear distribution. As shown in Fig. 7, during the filling process of the retaining wall, the earth pressure increases rapidly, and the base soil pressure is slightly after the construction. There is a decrease, and then it tends to be stable. The base pressure of the retaining wall measured on the spot is different from the measured base pressure. During the construction phase of the project, large construction machinery and pile packing have a great influence on the base pressure. Therefore, during the construction process, the measured base pressure is greater than the model. The base pressure was measured by the test. As the construction was completed, the construction machinery was withdrawn and the base pressure of the retaining wall was slightly reduced.

The geogrid flexible retaining wall has low requirements on the bearing capacity of the foundation. Whether it is a model test or on-site measurement, the ground soil pressure value after the stability of the shoulder-type flexible retaining wall is less than the theoretical calculation value (the theoretical base soil pressure is calculated directly by the packing bulk density multiplication. To the height of the retaining wall). The difference between this theoretical value and the measured value is related to whether the lateral deformation constraint is related to the lateral deformation constraint of the filler due to the consolidation of the soil around the earth pressure box. It deserves further research.

3.2 Wall horizontal earth pressure

Figure 8 is a graph showing the measured values of horizontal earth pressure at various positions of the retaining wall. These soil pressure values are measured after the completion of the retaining wall and the wall is stable. It can be seen from Figure 8 that each wall of the retaining wall The horizontal earth pressure on the upper part is not evenly distributed. The horizontal earth pressure in the middle of the retaining wall>the horizontal earth pressure on the inner side of the retaining wall>the horizontal earth pressure on the outer side of the retaining wall; the measured value of the earth pressure in the inner side of the retaining wall and the retaining wall presents a drum-shaped distribution. The /2H position reaches the maximum, and the horizontal earth pressure on the outside of the retaining wall is linearly distributed along with the wall height, reaching the maximum at the bottom of the retaining wall.

The horizontal earth pressure distribution characteristics of the shoulder-type flexible retaining wall are related to the physical properties and mechanical properties of the gravel geocell manufacturers, the mechanical properties of the fill, the compaction machinery, and the compaction process. First of all, during the construction process, the high quality gravel geocell is layered and paved. When the paving of the first floor is completed and the soil is loaded by the loader, when rolling with the road roller, when rolling to the position near the wall panel and the inner side of the wall, In order to ensure the smoothness and beauty of the line type, the peripheral edge of the roller is about 20cm from the inside of the panel and the retaining wall. The compaction process determines that most of the compactors are distributed in the middle of the width of the gravel geocell for sale layer, so the gravel geocell for sale layer The maximum pulling point is in the middle position. Secondly, it is related to the net effect of the inner cell layer of the retaining wall. When the horizontal earth pressure is transmitted inside the cell layer, the cell is deformed. When it reaches the middle, the cell deformation reaches the maximum, and its unloading and intercepting functions are fully exerted. Then, the earth pressure begins to gradually decrease, and there is almost no deformation when it reaches the edge baffle. Therefore, the horizontal earth pressure on the outer side of the retaining wall is very different from the inner side of the retaining wall and the retaining wall and is linearly distributed, similar to the rigid retaining wall.

The calculation of the horizontal earth pressure of the wall of the flexible retaining wall of the shoulder-type gravel geocell factory price is not covered in the “Code for Design of Highway Subgrade” (JTGD30-2015). The Coulomb active earth pressure method, the slice unit method and the differential element method are used in this paper. The theoretical calculation method is used to calculate the horizontal earth pressure of the wall. The dynamic load of the vehicle in the operation stage is also one of the important factors causing the horizontal deformation of the shoulder-type flexible retaining wall. The paper does not consider its impact on the retaining wall as a dynamic load. Instead, convert it to a permanent uniform load.

It can be found from Fig. 9 that the coulomb active earth pressure is linearly distributed along with the height of the retaining wall, and the calculation result is smaller than the measured value, especially between 1/3H and 2/3H of the wall height, and the calculated value and the measured earth pressure of the retaining wall. There is a big gap between the values, which means that the geogrid flexible retaining wall is the same as most retaining walls gravel geocell for sale. The earth pressure is between the three kinds of extreme soil pressures: active earth pressure, static earth pressure, and passive earth pressure. In the bit mode, the horizontal earth pressure value is calculated by the slice unit method, which is basically consistent with the measured horizontal earth pressure value distribution. However, since the slice unit method does not consider the overall deformation of the flexible retaining wall, the measured horizontal earth pressure value of the wall is compared. The engineering is actually too large; the differential element method divides the earth pressure behind the wall of the retaining wall into two parts to study. The maximum point in the middle is taken as the dividing point. Above the dividing point, the horizontal displacement of the wall is considered, according to the active soil of Cullen. The calculation of the pressure formula, below the demarcation point, the wall displacement is based on the rotation of the wall foot, calculated according to the displacement mode of the rotation around the bottom of the wall, which is consistent with the actual project, and the calculation results can be relatively close. The stress distribution of the reaction soil.

The project site monitoring results are significantly larger than the model test results, and the maximum soil pressure values are 57.62 kPa and 50.70 kPa, respectively. The reason for the analysis is that the model test is used to weaken the influence of different degrees of compaction on the test. Therefore, the test uses fine sand instead of relying on the loess used in the project. Loess is used as a filler and is easy to be consolidated with fine sand, which affects to some extent. The flexible deformation of the retaining wall and the deformation of the retaining wall are also an unloading process, so the horizontal earth pressure measured at the site is slightly larger than the model test.

3.3 Wall horizontal displacement

Figure 10 shows the horizontal deformation curve of the wall of the shoulder-type gravel geocell manufacturers flexible retaining wall with time. Figure 11 is a horizontal displacement comparison curve of the wall test and the field measured after the completion of the retaining wall with a wall height of 6 m.

The horizontal deformation of the cells of each layer can be seen from Fig. 10. It is mainly produced during the filling period of the upper layer of soil that is in direct contact. It can also be clearly seen at the construction site that when the upper layer of packing is crushed, the next layer of the cell body produces a significant horizontal displacement, and the outer baffle is significantly bulged and deformed. When the fill height of the retaining wall increases, the horizontal deformation of the filled wall chamber increases slowly or even slightly. After the retaining wall is completed, the deformation is basically stable. It can be seen that the deformation of the retaining wall is mainly caused during the construction period, and the construction period is a critical period for controlling the deformation of the retaining wall.

It can be seen from Fig. 11 that after the retaining wall is stabilized, the deformation of the wall is nonlinearly distributed with the increase of the height of the retaining wall. The deformation reaches a maximum of 5.32 cm at a height of 3 m, reaching 1.77% of the thickness of the wall. Inside (design limit deformation is 5% of wall thickness), indicating that the retaining wall has good stability. The deformation of the retaining wall is demarcated in the middle of the retaining wall. The horizontal deformation of the wall below the boundary becomes larger as the height of the retaining wall increases. The lower part of the boundary is just the opposite. This is related to the distribution of earth pressure on the wall of the retaining wall. At the bottom of the retaining wall, the earth pressure increases with the height of the retaining wall, which causes the wall deformation to increase with the height of the retaining wall. After the retaining wall reaches a certain height, the retaining wall The earth pressure begins to decrease, and the wall deformation of the retaining wall gradually decreases with increasing height.

4. Conclusion

(1) The geogrid flexible retaining wall has low requirements on foundation bearing capacity, and the base soil pressure increases with the increase of filling height, showing a non-linear distribution. During the filling process of the retaining wall, the earth pressure increases rapidly and the construction ends. The post-base soil pressure is slightly reduced and then stabilizes.

(2) The earth pressure on the same horizontal layer of the geogrid flexible retaining wall is not consistent, among which the earth pressure in the middle of the retaining wall> the earth pressure inside the retaining wall> the earth pressure outside the retaining wall. After the wall is stabilized, the earth pressure value between the inner side of the retaining wall and the retaining wall exhibits a drum shape, and the outer side of the retaining wall is linearly distributed.

(3) For the shoulder-type gravel geocell manufacturers flexible retaining wall, the theoretical calculation of the earth pressure on the wall, whether using the Coulomb active earth pressure calculation method or the slice unit method, is different from the measured value, and the differential element method is used. The measured values are closer.

(4) Influenced by the distribution of earth pressure, the horizontal deformation of the geotextile flexible retaining wall is drum-shaped and reaches the maximum in the middle of the retaining wall. In the design and construction process of the 6m high high quality gravel geocell flexible retaining wall, in order to ensure the safety of the wall and save materials, it is considered to establish a reinforced lattice chamber at a height of 3m.