Durability of High Strength Polypropylene Spunbonded Needled Geotextile

Abstract: In order to study the aging resistance and chemical corrosion resistance of high-strength polypropylene spunbonded needle-punched wholesale polyester nonwoven geotextile (HPP), experiments with thermo-oxidative aging, acid, and alkali etching solution and pure water immersion were carried out to study different temperatures and different chemistry. The effect of the environment on its durability is compared to the durability of conventional polypropylene wholesale polypropylene nonwoven geotextile (PP). The results show that the mass retention of HPP high quality polypropylene nonwoven geotextile is 99.06%, 98.85% and 98.10% when the samples are treated at 110, 120 and 130 °C. The mass retention of PP polyester nonwoven geotextile for sale is 98.89%. 98.78% and 97.78%; the longitudinal fracture strength retention rates of HPP polyester nonwoven geotextile factory price were 75.00%, 67.25%, and 64.71%, respectively, and the longitudinal fracture strength retention rates of PP polypropylene nonwoven geotextile factory price were 72.15%, 65.56%, and 54.00%, respectively. The strength loss rate of HPP polypropylene nonwoven geotextile manufacturers under three different liquid treatments did not exceed 5.00%, indicating that HPP polypropylene nonwoven geotextile for sale have good corrosion resistance and water immersion resistance. The expression of the thermal oxygen reaction rate of HPP polyester nonwoven geotextile manufacturers was fitted by Arrhenius theorem, and the strength retention rate of HPP high quality polyester nonwoven geotextile after 50a was predicted to be 27.30%.

Keywords: polypropylene spunbond needled wholesale polyester nonwoven geotextile; thermal oxygen aging; life prediction; durability; aging mechanism

filament nonwoven geotextile manufacturers, as a kind of geotechnical materials, have been widely used in highways, railway construction, agriculture, and environmental protection. Their development is of great significance for promoting industry progress and national economic construction. At present, wholesale filament nonwoven geotextile is divided into woven high quality filament nonwoven geotextile, woven filament nonwoven geotextile for sale, and nonwoven polyester nonwoven geotextile factory price according to different processing and production methods. Non-woven polyester nonwoven geotextile manufacturers have better extensibility, mechanical properties and horizontal penetrating filtration performance than woven and woven wholesale polypropylene nonwoven geotextile, and has low cost and high production efficiency. It is an ideal material for transportation, mining, and landfills, although it is better to start. Late, but rapid development. Polypropylene fiber non-woven polyester nonwoven geotextile for sale has the advantages of high strength, good acid and alkali resistance, corrosion resistance, low-temperature resistance, mildew resistance, lightweight and low cost, which makes it widely used in civil engineering, especially in The underground has an irreplaceable position in harsh environments such as acid, alkali and alpine.

At present, developed countries in Europe and the United States have established relevant standards for wholesale polyester nonwoven geotextile aging, such as ISO standards of the International Organization for Standardization, American ASTM and AATCC standards, and European EN standards. China has a late development and application of new high quality polypropylene nonwoven geotextile, and spunbonded nonwoven wholesale filament nonwoven geotextile is generally polypropylene nonwoven geotextile for sale. In recent years, the state has increased the development of polypropylene-spun clay fabrics. Domestic enterprises have developed new high-strength polypropylene spunbond needle-punched nonwoven high quality polyester nonwoven geotextile (HPP filament nonwoven geotextile factory price). Compared with ordinary polypropylene high quality filament nonwoven geotextile, HPP geotextiles have the advantages of high strength and good filterability; however, there is currently no experimental data on the aging resistance and corrosion resistance of HPP polypropylene nonwoven geotextile manufacturers, which restricts its promotion and use. Therefore, it is urgent to study The service life, failure and anti-aging mechanism of the new HPP polyester nonwoven geotextile factory price under the use of environmental conditions to evaluate the thermal oxidation and corrosion resistance of HPP wholesale polypropylene nonwoven geotextile. To this end, this paper conducted experimental and theoretical studies on the durability of filament nonwoven geotextile for sale under different temperatures by thermal oxygen aging experiments and acid, alkali corrosion and pure water immersion experiments, and analyzed the thermal oxygen aging and different corrosion of polypropylene nonwoven geotextile factory price at different temperatures. Corrosion resistance under environment; and establish HPP polyester nonwoven geotextile for sale life prediction equation for hot oxygen environment, in order to provide a reference for the promotion and application of HPP wholesale filament nonwoven geotextile.

1. Experimental part

1.1 Experimental materials and equipment

Polypropylene spunbonded filament nonwoven polypropylene nonwoven geotextile manufacturers, Tiandingfeng Nonwoven Fabric Co., Ltd.; chopped polypropylene wholesale polyester nonwoven geotextile, Shandong Lude Company; 1800W heating rod, Xin Shuguang Company; sulfuric acid, Shandong Dacheng Company; calcium hydroxide, Tianjin Junzheng Company.

KH-55A electric heating incubator produced by Shanghai Baum Instrument Co., Ltd.; H10K-S type mechanical testing machine produced by Hounsfield Company of the United Kingdom.

1.2 Preparation of geotextile samples

filament nonwoven geotextile manufacturers samples were sampled in accordance with GB/T13760-2009 “Surveying of Geosynthetics and Sample Preparation”. The high-strength polypropylene spunbond needle-punched high quality filament nonwoven geotextile specimen is referred to as HPP high quality polypropylene nonwoven geotextile, and the chopped polypropylene polyester nonwoven geotextile for sale specimen is referred to as PP wholesale filament nonwoven geotextile. The dimensions of the two filament nonwoven geotextile for sale are 300mm×200mm, and the caliper is used for accurate measurement with an accuracy of 0.02mm. The HPP polyester nonwoven geotextile manufacturers density is 200g/m2, and the PP polyester nonwoven geotextile factory price density is 400g/m2.

1.3 Thermal oxygen aging test method and performance test

The temperature of the hot oxygen aging experiment was set to 110, 120, and 130 °C. According to GB/T17631—1998 “Test Method for Antioxidation Performance of polypropylene nonwoven geotextile factory price and Related Products”, HPP and PP high quality polyester nonwoven geotextile are vertically suspended on the sample rack in the oven to avoid contact with metal and prevent accelerated degradation of wholesale filament nonwoven geotextile, which may affect the experimental results. In the whole experiment, the temperature fluctuation in the oven was not more than ±1 °C, the temperature distribution deviation was not more than ±1.5 °C, and the oxygen volume fraction in the air was 21%.

The filament nonwoven geotextile for sale was placed in an oven for thermo-oxidative aging for 25 days. Five wholesale polyester nonwoven geotextile samples were taken every 5 days, and the quality was tested with a balance of 0.5 g. According to GB/T15788-2005, polypropylene nonwoven geotextile for sale and related products were wide. The tensile test of the strip tests the fracture strength of the wholesale polypropylene nonwoven geotextile and analyzes the attenuation law of the mass and the fracture strength.

1.4 Chemical durability test method and performance test

According to GB/T17632—1998 “Test Methods for Acid and Alkali Resistance of wholesale filament nonwoven geotextile and Related Products”, three groups of chemical durability tests were carried out by acid, alkali corrosion and pure water immersion. The HPP high quality polyester nonwoven geotextile samples are placed in the container without any stress, and the spacing between the samples, between the samples and the container, and between the sample and the liquid surface is at least 10 mm. The sulfuric acid solution and the calcium hydroxide suspension were stirred at least once a day. The liquid and the sample were placed in the dark, and the temperature of the solution was maintained at (60 ± 1) °C by a thermostat device.

The corrosion period of each group of polyester nonwoven geotextile for sale in the three groups of durability tests was 20d. Five polypropylene nonwoven geotextile manufacturers samples were taken every 5d, and the samples were taken out in the water and then placed in a 0.01 mol/L ammonium carbonate solution. Wash, and finally rinse with water to ensure that the corrosive liquid is cleaned, air-dry at room temperature, and then measure the quality and fracture strength of polyester nonwoven geotextile manufacturers. The specific preparation method of the chemical solution is as follows.

(1) Acid corrosion test formula: sulfuric acid solution (pH=1.3) with a concentration of 0.025mol/L, and water of grade 3 for water (evaluating a classification of surface water quality in China).

(2) Alkaline corrosion test formula: saturated suspension of calcium hydroxide, the mass concentration of 2.5g / L (pH = 11.65), water is grade 3 water.

(3) Pure water immersion test formula: water is grade 3 water.

2. Results and discussion

2.1 Analysis of experimental results of thermal oxygen aging

2.1.1 Quality loss and analysis of geotextile samples

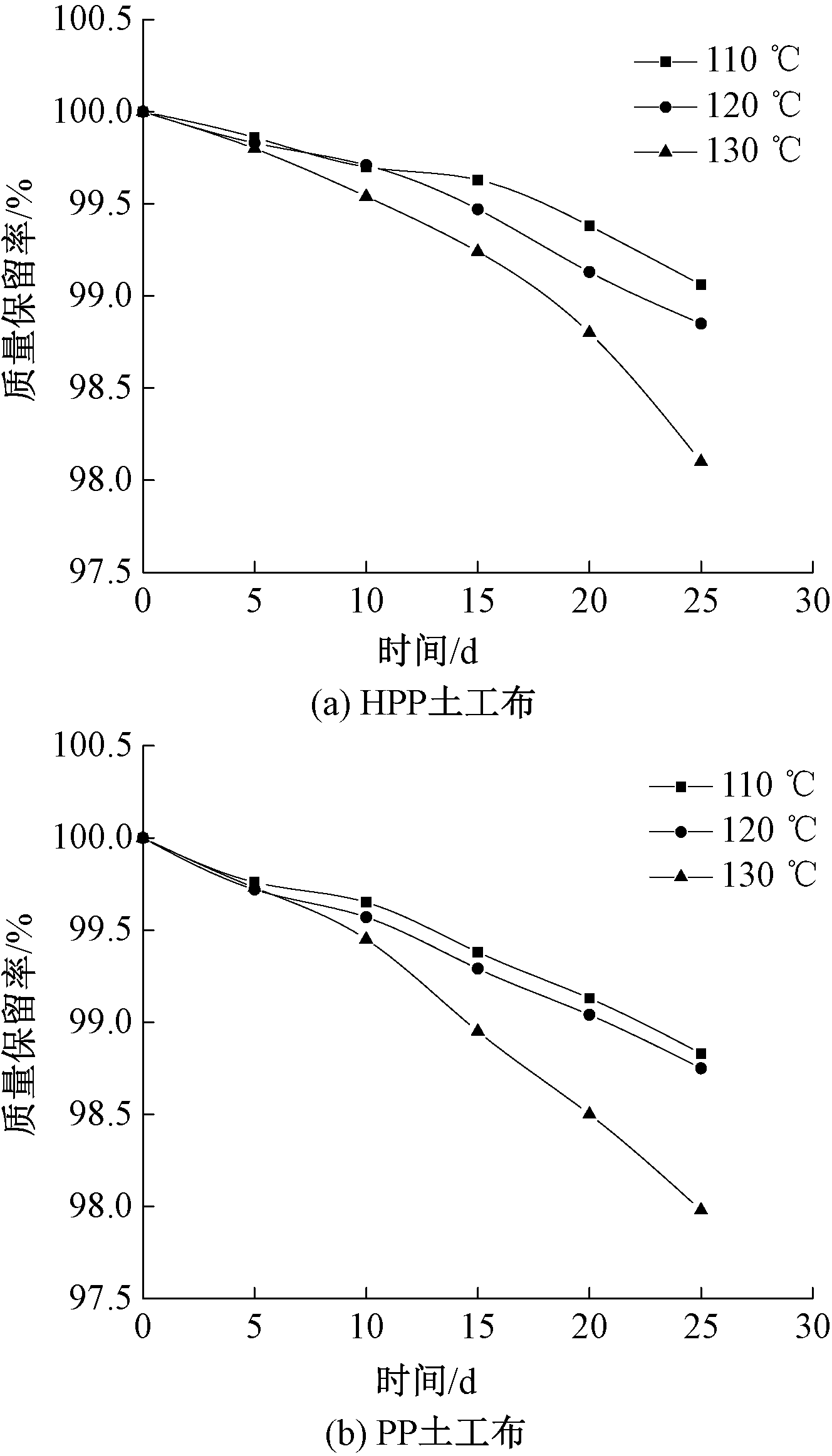

The thermal oxygen degradation of polypropylene is mainly the oxidation of the chemical bonds of the molecular chain. As the temperature rises, the chemical bond breaks and the physical function decreases, and the macroscopically shows the decrease in mass and strength. Figure 1 shows the relationship between mass retention rate and time after thermal oxidation of wholesale polyester nonwoven geotextile at different temperatures measured.

Fig.1 Curves of mass retention rate versus time in thermo-oxidative aging of HPP filament nonwoven geotextile manufacturers (a) and PP geotextiles (b)

It can be seen from Fig. 1 that at three temperatures, the mass retention rate of the HPP polyester nonwoven geotextile for sale gradually decreases with time, and the higher the thermal aging temperature, the faster the mass loss. As the temperature of the hot oxygen aging increases, the difference in the mass retention rate of the HPP polypropylene nonwoven geotextile manufacturers increases gradually. At 110 °C, the HPP wholesale filament nonwoven geotextile has a slower mass reduction in the first 15 days and the mass reduction rate increases after 15 days. This is because the thermal oxidation reaction of HPP polypropylene nonwoven geotextile for sale mainly occurs on the surface of the fabric in the first 15 days. With the extension of time, the thermal aging reaction gradually develops into the interior of the fabric, and the rate of thermal aging is accelerated. At 120 ° C, the thermal oxidation rate is accelerated by 5 days earlier than 110 ° C, indicating that the increase in temperature makes the HPP polyester nonwoven geotextile factory price thermal aging reaction rate faster. At 130 ° C, the slope of the curve increased significantly, indicating that the HPP high quality polyester nonwoven geotextile quality reduction rate is accelerated. The mass retention rates of the three kinds of high quality polypropylene nonwoven geotextile at 25d were 99.06%, 98.85%, and 98.10%, respectively. The quality variation law of HPP wholesale polypropylene nonwoven geotextile is similar: at 110 and 120 °C, the PP wholesale polyester nonwoven geotextile decreases slowly in the first 10 days and the slope of the curve increases after 10 days. At 130 °C, the mass reduction rate increases obviously after 5 days, and the mass retention rate at 25d. It is 97.78%.

The quality trends of the two polypropylene nonwoven geotextile factory price were similar at three temperatures, but at 110 °C, the mass loss rate of HPP and PP wholesale filament nonwoven geotextile began to increase for 15d and 10d, respectively. The final mass retention of HPP and PP filament nonwoven geotextile for sale at 25d The rates were 99.06% and 98.89%, respectively. It indicates that the thermal oxidation reaction of HPP high quality filament nonwoven geotextile develops from the fiber surface to the inside of the fiber later than PP filament nonwoven geotextile factory price, and the final mass retention rate is higher than that of PP polyester nonwoven geotextile manufacturers. At 130 °C, the slope of the mass retention curve of HPP wholesale filament nonwoven geotextile is significantly smaller than that of PP high quality polyester nonwoven geotextile. The mass retention rate at 25d is 98.10% and 97.78%, respectively. It indicates that the higher the temperature, the greater the difference in thermal oxidation resistance between HPP and PP high quality polypropylene nonwoven geotextile.

2.1.2 Analysis of mechanical properties of geotextile samples

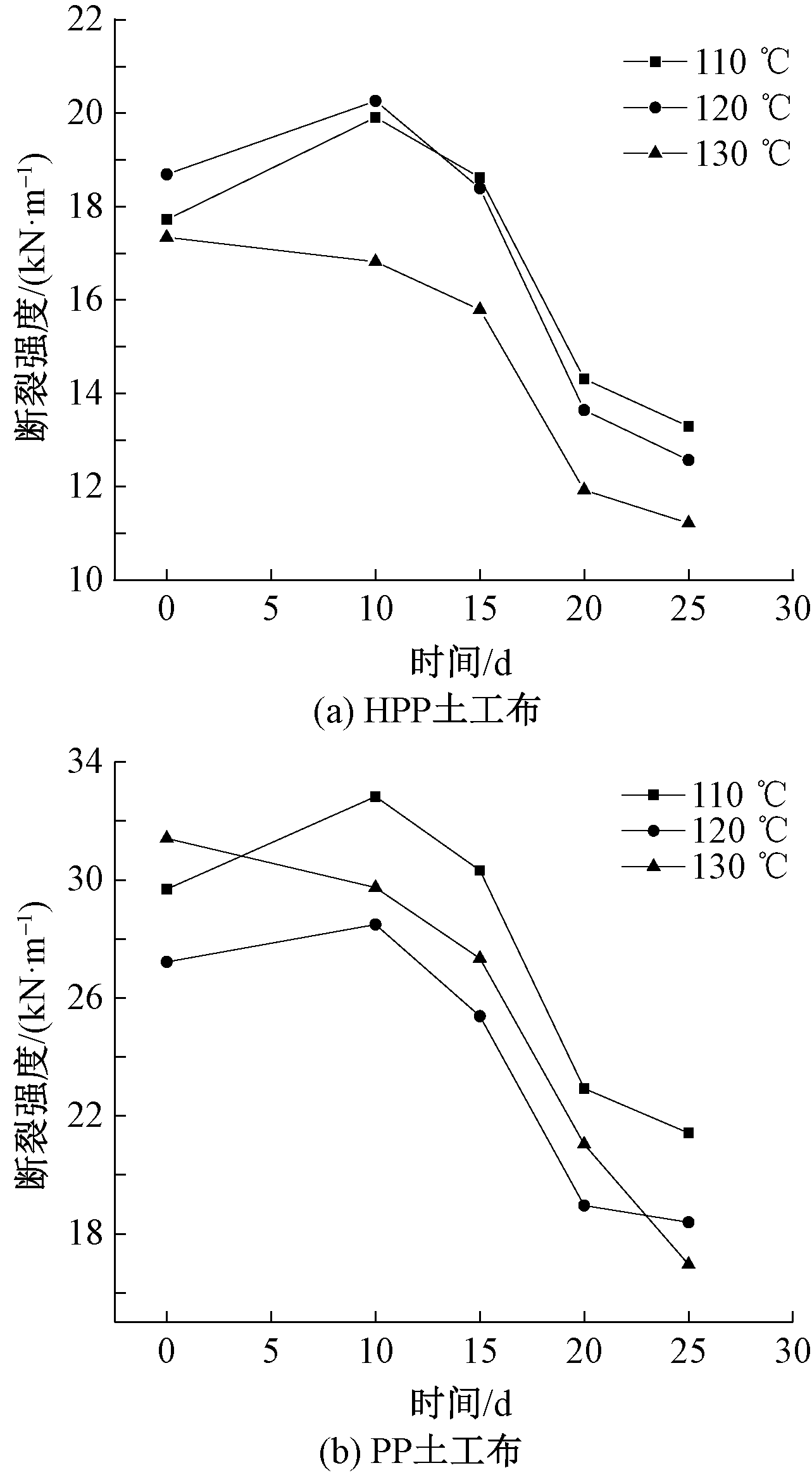

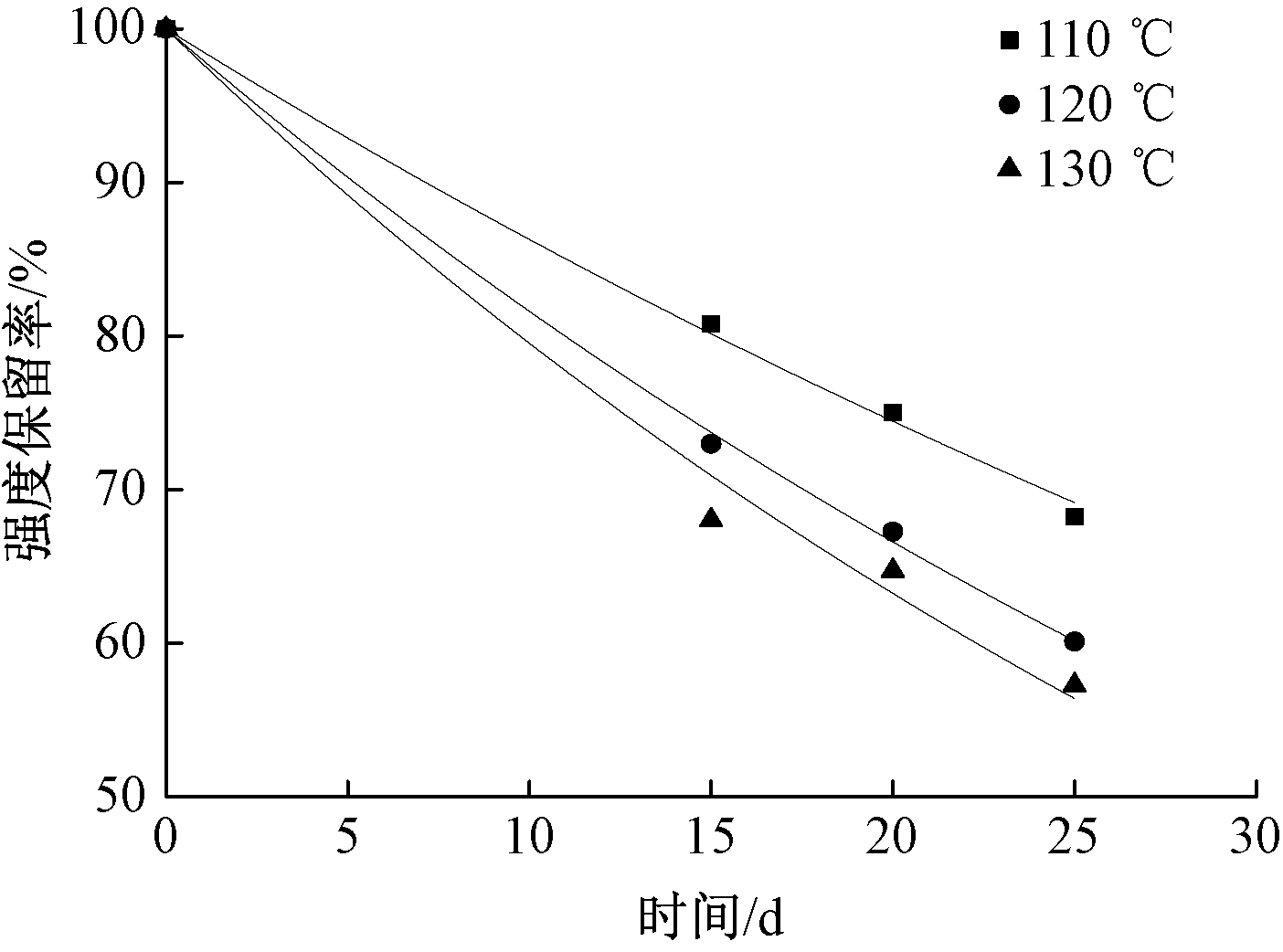

The relationship between the fracture strength of two polyester nonwoven geotextile for sale and the thermal aging time at different temperatures is shown in Fig. 2. Among them, the experimental data of HPP polypropylene nonwoven geotextile for sale was more discrete at 130 °C, and the coefficient of variation of the five groups of data under the five thermal aging time was 2.5%, 5.2%, 6.1%, 6.5%, and 8.5%. The PP filament nonwoven geotextile for sale has a large data dispersion at 120 °C, and the coefficient of variation of the five groups of data is 1.5%, 3.6%, 5.8%, 6.5%, and 9.5%, respectively. The breaking strength retention rates of the two wholesale polypropylene nonwoven geotextile are shown in Figure 3.

Fig.2 Curve of longitudinal breaking strength and thermo-oxidative aging time of HPP high quality filament nonwoven geotextile (a) and PP geotextiles (b) at different temperatures

It can be seen from Fig. 2 that the process of reducing the fracture strength in the thermal aging reaction of the two kinds of high quality polypropylene nonwoven geotextile has experienced three main stages of mitigation-violent-tempering. When the HPP filament nonwoven geotextile for sale was at 110 °C and 120 °C, the longitudinal fracture strength increased slightly in the first 10 days, and the longitudinal fracture strength increased by 12.36% and 8.39% at 10 days. At 110 °C, the longitudinal fracture strength of HPP polyester nonwoven geotextile factory price began to decrease slowly from 10 to 15 days. The reaction at this stage was moderate, the fracture strength decreased rapidly from 15 to 20 days, and the rate of longitudinal fracture strength decreased after 20 days. At 120 °C, the longitudinal fracture strength of HPP polypropylene nonwoven geotextile factory price decreased rapidly after 10 days. At 130 °C, the longitudinal fracture strength of HPP polyester nonwoven geotextile for sale did not increase, and it showed a significant downward trend. The longitudinal fracture strength decreased at 15-20 days, and the longitudinal fracture strength decreased from 20 to 25 days. The longitudinal fracture strength of HPP wholesale polyester nonwoven geotextile at three temperatures was 13.41, 12.62, and 11.22 kN/m, respectively.

The longitudinal fracture strength of PP wholesale polypropylene nonwoven geotextile shows that the change of longitudinal fracture strength of PP and HPP filament nonwoven geotextile for sale is similar at 110 and 120 °C. The decline rate of PP polypropylene nonwoven geotextile for sale is much faster than that of HPP polypropylene nonwoven geotextile manufacturers in the first 10 days, especially during 10-15 days. Significantly; the longitudinal fracture strength of PP wholesale filament nonwoven geotextile has been rapidly decreasing at 130 °C. The final longitudinal rupture strength of PP polyester nonwoven geotextile manufacturers at the three temperatures was 21.72, 18.39, 16.96 kN/m.

The fracture strength changes of HPP and PP high quality polyester nonwoven geotextile can be divided into four stages: slight increase, moderate decrease, sharp decrease, and relaxation. The mechanism is: polypropylene is a crystalline polymer. In the early stage of 0-10 days, the internal crystallization of the molecule continues to develop due to the thermal aging environment, the fracture strength will rise slightly, and the chemical properties of the high quality polypropylene nonwoven geotextile are relatively stable. In the medium term, 10-15 days, The influence of thermal oxygen on the damage of the material gradually appeared. The aging began to expand into the interior of the material, and the breaking strength slowly decreased. In the later period of 15-20 days, the concentration of active intermediates such as peroxide accumulated in the material became higher and higher. The rate of oxygen aging is accelerated, and the thermal aging reaction extends to the inside of the material, causing the destruction of polypropylene macromolecules, resulting in a rapid decline in fracture strength; the rate of thermal aging is gradually slowed after 20-25 days.

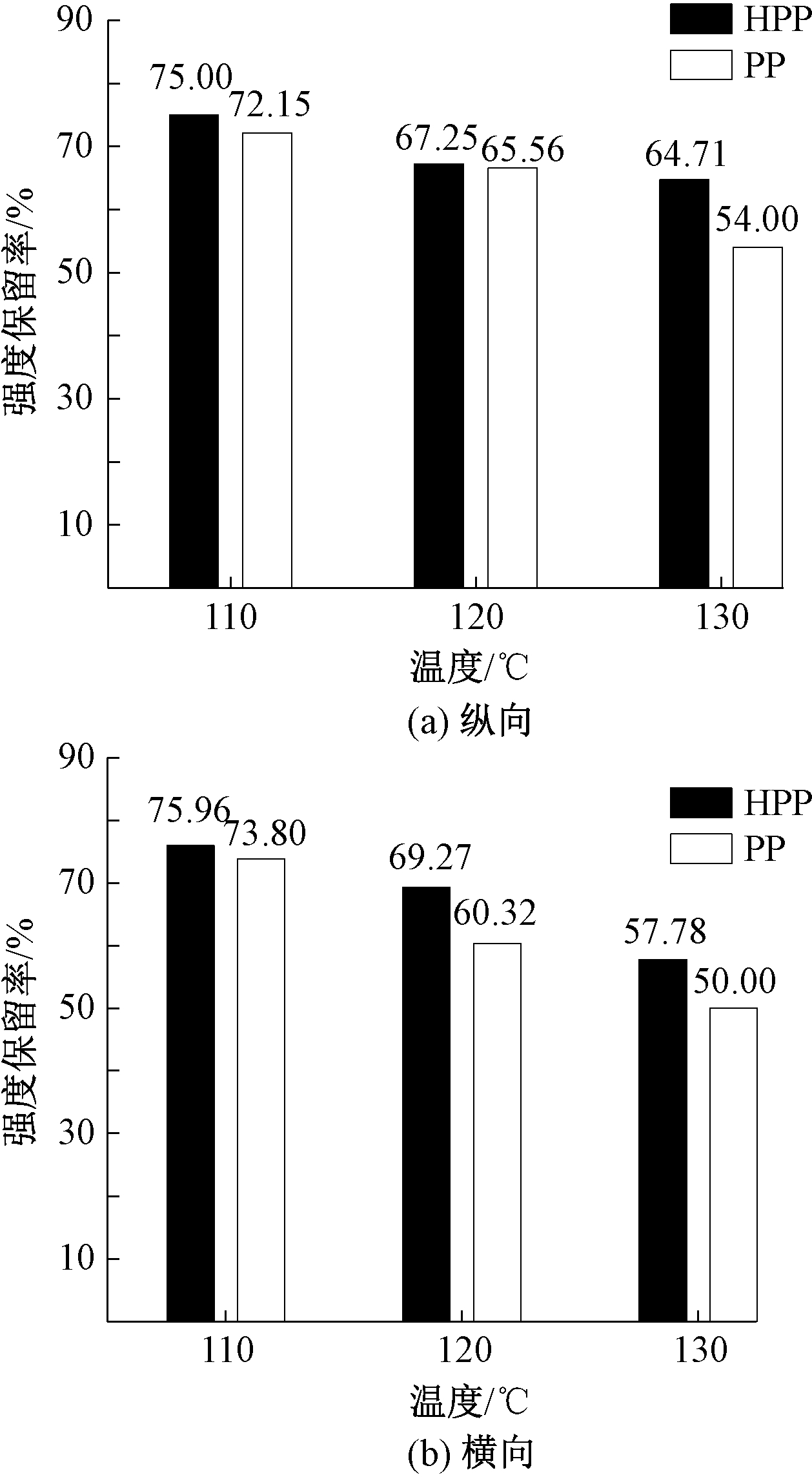

Figure 3 shows the longitudinal and transverse rupture strength retention rates of two polyester nonwoven geotextile factory price. It can be seen that with the increase of the thermal aging temperature, the strength retention rates of the two wholesale polypropylene nonwoven geotextile show different degrees of decline. At the same temperature, the HPP wholesale polyester nonwoven geotextile has better resistance to thermal aging than PP filament nonwoven geotextile for sale. The vertical and horizontal strength retention rates of HPP filament nonwoven geotextile manufacturers at 1200°C were higher than those of PP high quality filament nonwoven geotextile by 2.85% and 2.16% respectively. The longitudinal and transverse strength retention rates of HPP geotextiles at 120°C were higher than PP filament nonwoven geotextile manufacturers by 1.69% and 8.95%. The longitudinal and transverse strength retention rate of HPP polypropylene nonwoven geotextile factory price is higher than that of PP polypropylene nonwoven geotextile manufacturers by 10.71% and 7.78%. With the increase of temperature, the difference of heat-resistant oxygen aging properties of the two filament nonwoven geotextile factory price gradually appeared. The horizontal and longitudinal strength retention rate of HPP high quality filament nonwoven geotextile was significantly higher than that of PP filament nonwoven geotextile for sale. That is, the temperature rises, and the HPP filament nonwoven geotextile factory price has better resistance to thermal aging than PP polypropylene nonwoven geotextile for sale.

Fig.3 Longitudinal (a) and lateral (b) breaking strength retention rate of two geotextiles

2.1.3 HPP geotextile life calculation

HPP high quality polyester nonwoven geotextile life chemical reaction metering method is

aA+bB+cC→eE+fF

The chemical reaction rate γ can be defined as

γ=k[A]a[B]b[C]c

Where: [A], [B], [C] are the concentrations of the reactants; a, b, c, e, and f are the coefficients of the equilibrium chemical reaction, related to the concentration of the reactants and products; The chemical reaction rate is constant and is related to the temperature and pressure of the chemical reaction.

The number of chemical reaction rates n is

n=a+b+c

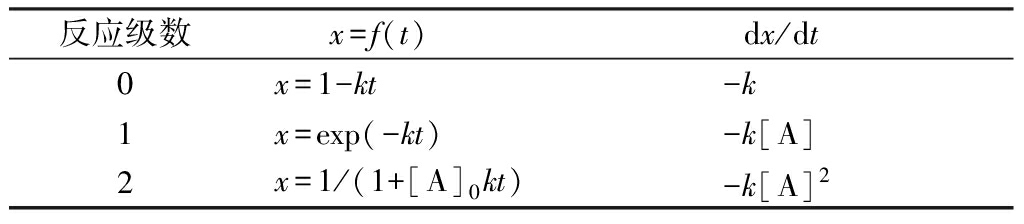

Most chemical reactions have a rate series of 0, 1, or 2. The chemical reaction rates of each chemical reaction order are shown in Table 1. In the table: [A]t is the concentration of reactant A at time t; [A]0 is the initial concentration; x=[A]t/[A]0, expressed by the equation x=f(t), and the reaction rate is dx/dt said.

Tab.1 Chemical reaction rates

The aging reaction order of the high molecular polymer is usually 0, 1 or 2. Since the reaction order of the thermal aging of the material cannot be determined in advance, the experimental data can only be substituted into the respective functions of Table 1, and the deviation is the smallest ( The correlation coefficient is the largest), which is the equation of the reaction series, to determine the reaction rate constant of the material at different temperatures. Linearly fit in with Arrhenius data graph of corresponding temperature 1/T, determine the equation lnk=a(1/T)+b, and find the reaction rate constant at a certain temperature T0: k(T0)=exp[ a(1/T0)+b]. After obtaining the reaction rate constant k(T0), the retention rate of wholesale polyester nonwoven geotextile strength x(t)=F(t)/F0 can be calculated for a given time t. The specific calculation process is as follows: the thermal aging temperature is 110, 120 respectively. At 130 ° C, the oxygen concentration was the standard atmospheric oxygen concentration, and the three chemical reaction series functions in Table 1 were used for fitting. By comparison, the correlation of the first-order reaction function fitting was the best, and the result was as shown in Fig. 4, and the number of the thermo-oxidative aging reaction was determined to be 1.

Fig.4 Fitting curve of thermo oxidative aging order 1 reaction

The rate constant k of the thermal aging reaction of HPP polypropylene nonwoven geotextile for sale at three temperatures were obtained from the fitting function, which was 0.01182, 0.01829, and 0.02482, respectively.

Using the Arrhenius formula as a straight line between the dependent variable link and the independent variable 1/T, the reaction rate function equation is obtained.

Lnk=-5677.44/T+10.35592

The annual average temperature in Beijing is 12.2 °C, and the volume fraction of oxygen is 21%. The calculated rate constant of thermal aging of HPP polypropylene nonwoven geotextile manufacturers is lnk=-5677.44/(273+12.2)+10.35592=-9.551, then k=7.113×10- 5. Assuming the engineering design period of 50a, the strength retention rate of HPP high quality polyester nonwoven geotextile at 50a in a hot oxygen environment is x(50)=e-kt=e-7.113×10-5×365×50=27.30%.

2.2 Analysis of chemical durability test results

2.2.1 Quality loss and analysis of HPP geotextile samples

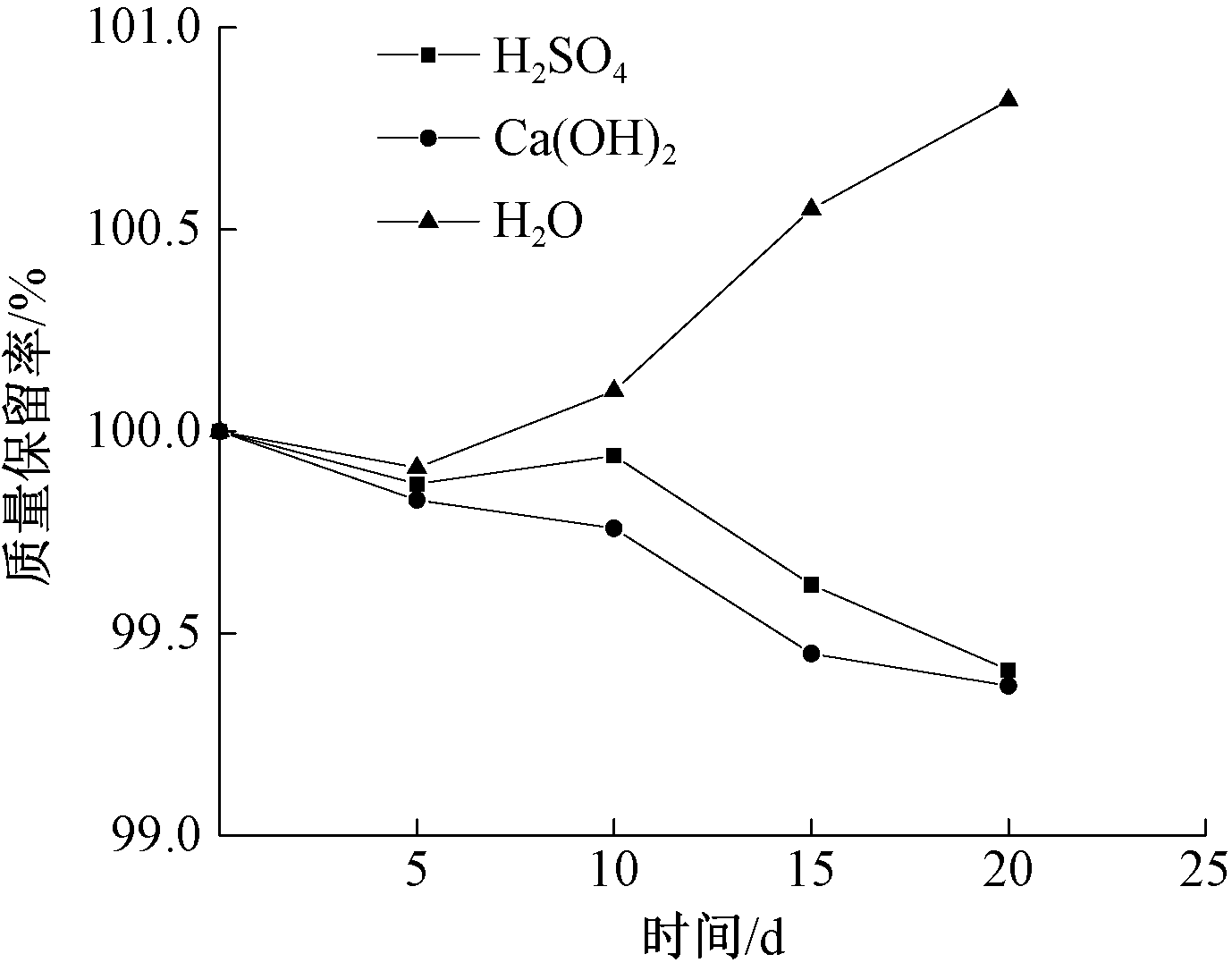

The literature shows that ordinary polypropylene polyester nonwoven geotextile factory price (PP) has good chemical corrosion resistance. Therefore, this paper focuses on the acid, alkali and water immersion resistance of HPP high quality polypropylene nonwoven geotextile. The relationship between mass retention rate and time of HPP polyester nonwoven geotextile manufacturers at different temperatures and solutions is shown in Fig. 5.

Fig.5 Mass retention rates of HPP filament nonwoven geotextile factory price in different liquid environments

The HPP high quality filament nonwoven geotextile has a final mass retention rate of 99.41% in a sulfuric acid environment (pH=1.3) with a concentration of 0.025 mol/L; an alkaline environment (pH=11.65) of a calcium hydroxide suspension with a mass concentration of 2.5 g/L. The mass loss is the largest, and the final mass retention rate is 99.37%. However, the quality of HPP polyester nonwoven geotextile manufacturers increases in a pure water environment. This is because water molecules are smaller than other ions, and the rate of penetration into HPP wholesale polypropylene nonwoven geotextile is greater, making it easier for water molecules to continue along the macromolecular chains of polypropylene or the interstitial segments of polypropylene. Infiltration into the interior of the polypropylene nonwoven geotextile factory price results in an increase in the quality of the HPP polypropylene nonwoven geotextile for sale is a pure water environment. In an acid or alkali environment, the sulfate ions and calcium ions of the solute combine with water molecules to form hydrated ions, which increases the molecular radius and reduces the rate of diffusion into the polypropylene material. It can be seen that the HPP polyester nonwoven geotextile for sale has an increased mass in water, and the mass is less reduced in an acid environment, and the mass is greatly reduced in an alkaline environment. However, in the two kinds of corrosive liquids, the mass-loss rate did not exceed 1.0%, indicating that the HPP high quality polypropylene nonwoven geotextile has good acid resistance and alkalinity.

2.2.2 Strength loss and analysis of HPP geotextile samples

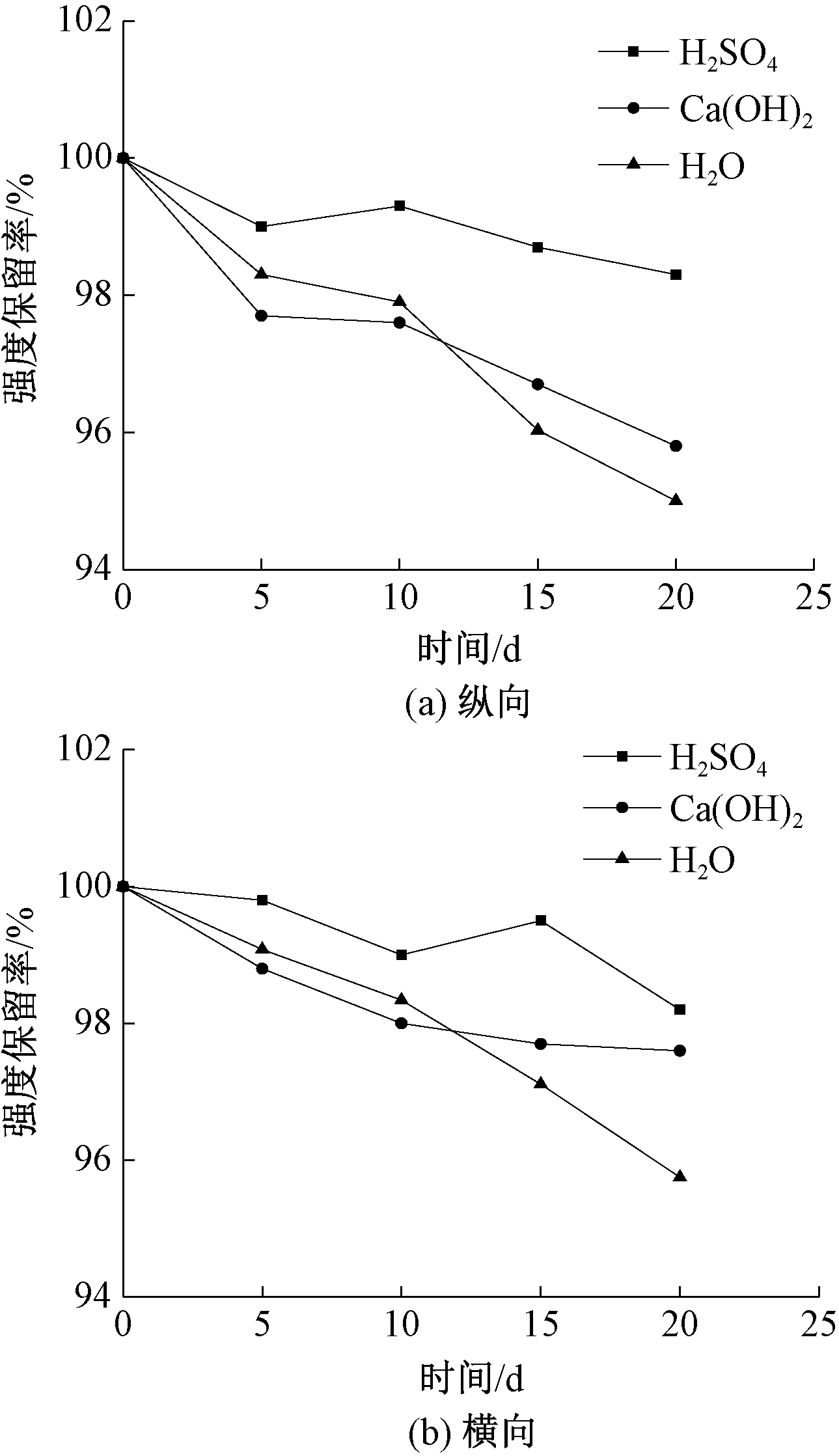

The relationship between the longitudinal and transverse fracture strength retention rate and time of HPP polyester nonwoven geotextile factory price in different liquid environments and at different times is shown in Fig. 6. Among them, the HPP high quality polyester nonwoven geotextile has a large intensity dispersion in the sulfuric acid solution, and the coefficient of variation of the five groups of data is 2.1%, 1.5%, 5.6%, 4.8%, and 5.0%, respectively.

Fig.6 Curves of longitudinal (a) and lateral (b) breaking strength retention rate and time of HPP filament nonwoven geotextile factory price

It can be seen from Fig. 6 that the longitudinal and transverse fracture strength retention rates of HPP polypropylene nonwoven geotextile manufacturers are similar, and the curves are relatively flat, indicating that the HPP high quality filament nonwoven geotextile strength attenuation is small under different liquid environments. At 20 days, the transverse and longitudinal rupture strength retention rates of HPP polypropylene nonwoven geotextile for sale in the acid environment with a sulfuric acid concentration of 0.025 mol/L were 98.20%; in the alkaline environment of 2.5 g/L calcium hydroxide suspension, the longitudinal strength retention rate It is 95.80%, the transverse strength retention rate is 97.60%; the longitudinal strength retention rate in pure water is the smallest, 95.00%, and the lateral strength retention rate is 95.75%. It can be seen that the HPP high quality polypropylene nonwoven geotextile has the greatest loss of strength in the pure water environment at 20 days, and the alkali environment is the next, and the acid environment is the smallest. The reason is: polypropylene is composed of a large number of non-polar polymer equivalent alkane chains. When polypropylene is immersed in non-oxidizing acid and alkali solution, ions in acid and alkali form hydration ions with water molecules, which increases the molecular radius. The diffusion rate of the hydration ions into the interior of the polypropylene molecule is reduced, and even when the hydration ions penetrate into the polypropylene molecule, the molecular structure is not changed by chemical reaction with the polypropylene molecule. That is to say, the infiltration of these media does not eliminate van der Waals forces between macromolecules, or the effect is very weak.

The water molecule has a small volume, and the penetration rate of the polypropylene material is large. After the water molecules penetrate into the polypropylene molecule, the anti-oxidation and other related additives in the polypropylene molecular system and other soluble substances are dissolved, migrated or extracted, resulting in HPP. The fracture strength of filament nonwoven geotextile manufacturers decreases more. Overall, the polyester nonwoven geotextile factory price did not undergo significant strength decay in the three liquids, indicating that HPP polyester nonwoven geotextile for sale has good resistance to acid, alkali and water immersion.

3. Conclusion

(1) With the prolongation of thermal oxygen aging time, the quality and transverse and longitudinal fracture strength of HPP and PP polyester nonwoven geotextile manufacturers decreased to different extents; at the same temperature, the thermal aging performance of HPP high quality filament nonwoven geotextile was better than that of PP polypropylene nonwoven geotextile factory price. As the temperature increases, the HPP filament nonwoven geotextile manufacturers exhibit better thermal aging resistance.

(2) When the temperature is 110, 120, 130 °C thermal oxygen aging to 25d, the HPP filament nonwoven geotextile factory price quality retention rate is 99.06%, 98.85% and 98.10%, respectively, while the PP filament nonwoven geotextile factory price quality retention rate is 98.89%, 98.78%, and 97.78%; the longitudinal fracture strength retention rates of HPP geotextiles were 75.00%, 67.25% and 64.71%, respectively, and the longitudinal fracture strength retention rates of PP filament nonwoven geotextile manufacturers were 72.15%, 65.56%, and 54.00%, respectively. It shows that HPP has better heat-resistant oxygen aging performance than PP filament nonwoven geotextile factory price and has good heat-resistant oxygen aging properties.

(3) According to the Arrhenius theorem, the expression of the thermal oxygen reaction rate of HPP wholesale polypropylene nonwoven geotextile is fitted. Based on the environmental conditions in Beijing, it is predicted that the HPP polypropylene nonwoven geotextile factory price has a strong retention rate of 27.30% after 50a in a thermo-oxidative aging environment.

(4) HPP filament nonwoven geotextile factory price has increased mass in water, less mass reduction in an acid environment, and greater mass loss in an alkaline environment; and in both corrosive liquids, the mass-loss rate does not exceed 1.00%, HPP polypropylene nonwoven geotextile factory price Shows good acid and alkali resistance.

(5) The horizontal and vertical rupture strength retention ratio of HPP polypropylene nonwoven geotextile manufacturers in 0.025mol/L acid environment is 98.20%; in the alkali environment of 2.5g/L calcium hydroxide suspension, the longitudinal strength retention rate reaches 95.80%. The longitudinal strength retention rate in pure water is 95.00%. The HPP filament nonwoven geotextile manufacturers were immersed in acid, alkali corrosion and pure water for 20 days, and the strength loss rate did not exceed 5.00%, indicating that the HPP polyester nonwoven geotextile manufacturers have good acid, alkali, and water immersion resistance.