Advances in Geomembrane Seepage Prevention Technology for Reservoir Dams in China

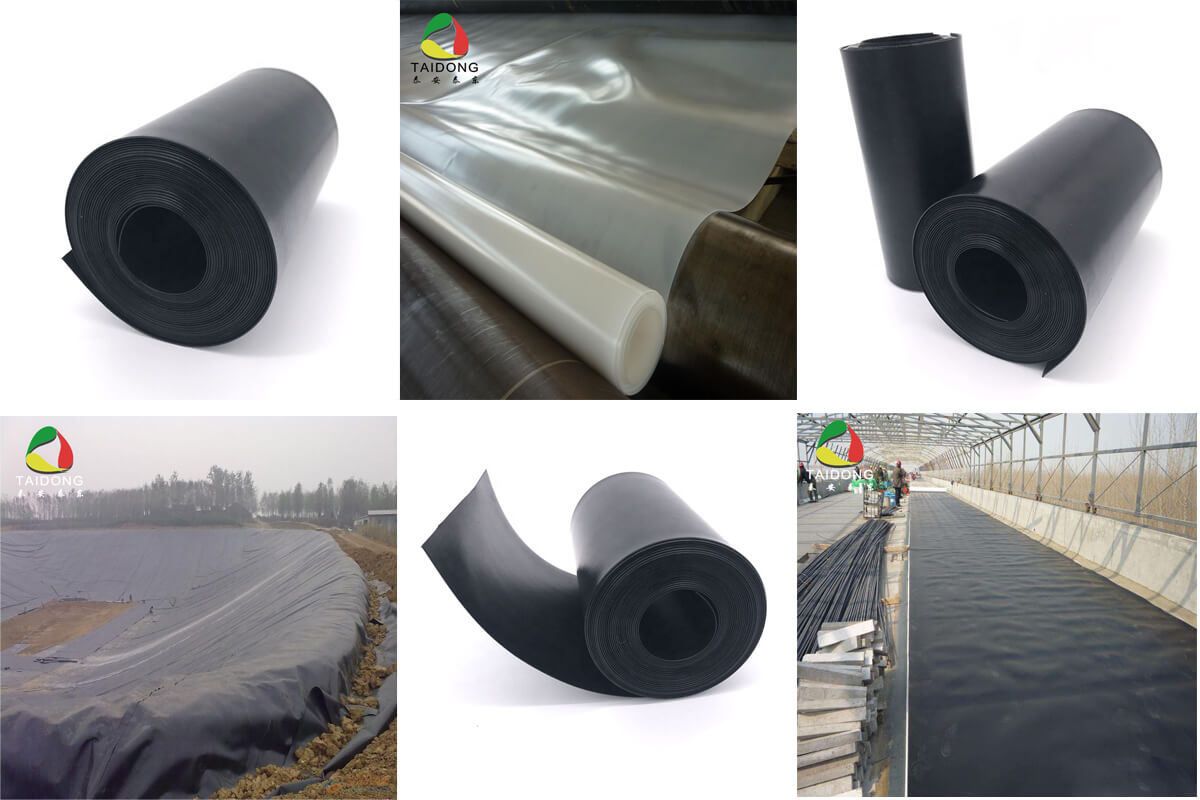

Abstract: The effective implementation of HDPE geomembrane manufacturers seepage prevention technology in reservoir dam project can effectively enhance the impermeability of the surrounding land of the reservoir and avoid the impact of the external environment on the reservoir dam foundation. On the other hand, the characteristics of high quality HDPE geomembrane materials It is also possible to isolate the erosion of the dam body material by the surface water body in order to ensure the construction quality of the reservoir dam engineering system. Based on the analysis of the characteristics of high quality aquaculture geomembrane anti-seepage technology, this paper hopes to provide a good reference for the construction of China’s reservoir dam engineering system while clarifying the design points and calculation methods.

Keywords: reservoir dam; HDPE geomembrane manufacturers seepage prevention; technical measures; progress analysis

1. Overview of geomembrane anti-seepage technology

The high quality HDPE geomembrane anti-seepage technology is a new anti-seepage measure based on the demand for disease prevention and control of reservoir dams in China. From the point of view of technical advantages, this technology can effectively isolate the influence of external water bodies and natural environment on the dam structural system, so that the overall dam foundation quality can be better protected, and at the same time, according to the economic and functional characteristics of the materials, Facilitate material replacement and repair, thus continuously guaranteeing the quality level of the reservoir dam project.

From the perspective of reservoir engineering structure, this material has good ductility, impermeability, pressure resistance environmental geomembrane manufacturers, bending resistance and direct shear resistance. After years of testing data and technical reserves, such materials are the use in the project is more in line with the needs of environmental factors such as basic mechanics, permeable requirements and dam deformation, thus greatly protecting the functional environment of the reservoir and reducing the probability of occurrence of cracks in the cushion. Therefore, from the perspective of the sustainability of the reservoir dam project, the implementation of HDPE geomembrane manufacturers anti-seepage technology has effectively enhanced the controllability of project management, reduced the damage that may be caused by the external environment, and has also been greatly improved in construction technology. The simplification has greatly improved the construction quality level of the overall impermeability system and laid a solid foundation for the subsequent engineering system construction.

2. Analysis of the main points of geomembrane anti-seepage design

2.1 Progress in impermeability design calculation

In the 1980s and 1990s, the anti-seepage type of the dam surface in the anti-seepage reinforcement of reservoirs and earth dams was adopted. The anti-seepage type of the composite high quality HDPE geomembrane dam surface was covered, and the contact scouring from the interface of the paved and permeable foundation was carried out. Based on the concept, the calculation formula of the limit cover length and seepage flow is derived. According to film theory, the calculation formula of the burst strength of the composite HDPE geomembrane manufacturers under normal stress is established. At the beginning of the 21st century, relevant research was continued on the basis of considering the dam surface impermeable membrane covering the soil.

From the 1990s to the beginning of the 21st century, the calculation formula for the leakage of different water-permeable cushions was established for the leakage of low-head anti-seepage membrane defects in environmental engineering, and the non-saturated seepage finite element method was used to analyze the leakage film of the anti-seepage membrane defects. The environmental geomembrane manufacturers seepage field can be used for the leakage analysis of the dam seepage membrane in similar working conditions; the relationship between the void size of different mat particles, the thickness of PE film and the ultimate load of liquid expansion is summarized by the hydraulic burst test; The hydraulic bursting test of PE and PVC film under different pore size and different scratch damage conditions shows that the liquid swelling strength of the film decreases with the increase of the damage degree of the film, and the tangential deformation modulus of the film decreases. The maximum strain does not decrease; the strength of the high quality aquaculture geomembrane expansion of different degrees of damage is obtained. In 2010, the probabilistic analysis method was used to explore the risk assessment of the anti-seepage membrane on the dam surface cushion by the hydraulic top expansion.

2.2 Deformation calculation and prevention measures

Based on engineering mechanics, soil mechanics and hydraulics, considering the behavior of the impermeable membrane in the structure and its evaluation is the core content of the design method environmental geomembrane manufacturers. Although China’s research in this area is not comprehensive and in-depth, it is also constantly improving.

At the beginning of the 21st century, relevant experts elaborated the fixture effect of the anti-seepage membrane of the high-headed membrane rockfill dam. The impermeable membrane is sufficient to accommodate the displacement of the dam up to about 1% of the dam height in the average sense, but at the surrounding anchorage, Due to the small displacement of the surrounding bedrock or concrete structure, the anti-seepage film undergoes relatively large deformation in the extremely small space of the anchorage with the displacement of the dam body, which is equivalent to the two adjacent clamps stretching the anti-seepage film. Destruction environmental geomembrane manufacturers, the so-called “fixture effect”; after a few years of separation, the deformation of the anti-seepage film on the dam surface should be superimposed on the deformation caused by the displacement of the anti-seepage film with the dam body. Design concept; the temperature stress and stress relaxation evaluation results of the impermeable membrane can be used as a reference for engineering design. At the beginning of 2010, the research on the experimental demonstration, principle analysis and design of the “fixture effect” continued to progress; the deformation and local hydraulic expansion deformation of the dam surface anti-seepage film with the displacement of the dam and the dam surface prevention were given. The numerical calculation method of the “clamp effect” of the film.

3. Analysis of geomembrane anti-seepage construction technology

3.1 Laying technical analysis

According to the actual project history, the HDPE geomembrane manufacturers anti-seepage system needs to be analyzed according to the geotechnical environment around the reservoir dam project to ensure that the local soil and water subsidence rate and other factors will not affect the laying quality, and can provide a more comprehensive use of the dam engineering system. Protection. Taking the Three Gorges Reclamation Project in the Yangtze River as an example, in the late 1990s, the construction plan for the rapid construction of closed-air cofferdams in open channels was proposed. During the period, the concept of pre-embedded high-strength reinforced membranes was effectively implemented, which not only effectively consolidated the cofferdam project. The surrounding environment reduces the damage to the high quality HDPE geomembrane from the outside. At the same time, the high-strength reinforcement measures enhance the overall rigidity of the high quality aquaculture geomembrane anti-seepage system and provide a more complete maintenance system for the construction of the dam anti-seepage project.

3.2 Analysis of splicing technology

The high quality aquaculture geomembrane anti-seepage system is an anti-seepage system formed by splicing finished films. From a functional point of view, such impervious systems need to ensure their containment and integrity, in order to avoid the external water and soil environment eroding the dam structural system. From the existing reservoir engineering cases, most of the areas have selected the PVC composite film on-site welding and bonding process, so by virtue of the welding strength and bonding density, effectively enhance the integrity and tightness of the joint, and by virtue of material properties, It has the characteristics of adaptability to the climatic environment, and by virtue of the toughness and corrosion resistance of the material, it effectively reduces the intrusion of the external environment against the seepage project. However, during the implementation of the splicing technology, it is necessary to ensure that the thickness of the welded portion and the surrounding film layer are consistent, and the deviation between the bearing capacity and the elastic variable is avoided.

3.3 Anchorage Technology Analysis

During the implementation of anchoring technology, it is necessary to analyze the sealing property of HDPE geomembrane manufacturers anti-seepage to ensure that the holes can be repaired in time during anchoring and the whole material can be strengthened to effectively reduce the influence of elastic variables and other factors on the impermeability of the project. It also avoids the possibility of wear of the high quality HDPE geomembrane anti-seepage system.

4. Analysis of geomembrane anti-seepage observation technology

Due to the fact that the deformation of the impermeable membrane is much larger than that of the concrete, the advancement of the anti-seepage membrane prototype observation technology is relatively lagging, and there are few projects for the prototype observation of the anti-seepage membrane.

4.1 Development of large strain gauges

In order to meet the prototype observation requirements of the large deformation of the anti-seepage film as a flexible material, in the late 1990s, large deformation strain gauges with corresponding strains of 15% to 20% and corresponding bonding materials were developed, which were dam reservoirs. Prototype observation of membrane anti-seepage structures provides relatively convenient conditions.

4.2 Anti-seepage deformation observation

It can be seen from the Yangtze River Three Gorges cofferdam project in the last century that the high quality aquaculture geomembrane strain gauges embedded in different elevations upstream meet the requirements of engineering foundation impermeability, and the observation values from some high quality HDPE geomembrane strain gauges show that before and after the summer flood season, Some observation points have a steep increase in strain. This change proves that the strain detection results are related to the loading rate during the construction of the cofferdam, and this viewpoint was confirmed by site survey during the subsequent cofferdam demolition process.

5. Conclusion

The effective implementation of the environmental geomembrane manufacturers anti-seepage engineering system can not only improve the impermeability of the reservoir dam and other projects but also provide a more comprehensive technical guarantee for the construction of the overall dam functional system. At the same time, it can reduce the construction pair. The impact of the surrounding environment of the reservoir, relying on the corrosion resistance of environmental geomembrane manufacturers materials, has built a longer-term platform for the sustainable use of the project. Therefore, during the progress of the high quality aquaculture geomembrane anti-seepage technology of the Chinese reservoir dam, it is necessary to clarify the characteristics and related materials of the civil-membrane anti-seepage engineering system to ensure that the construction quality and technical advantages can be effectively detected and utilized, in order to be the follow-up reservoir hero. The construction of the system provides quality assurance.