Application of Geogrid Technology in Construction of Expressway Subgrade

Abstract: Firstly, the characteristics of wholesale biaxial geogrid technology are introduced. Then, combined with engineering examples, the application of biaxial geogrid for sale technology in highway subgrade construction and the application strategy is proposed, including subgrade treatment, high quality biaxial geogrid laying, filling, and scrolling. Grid and other content. The conclusion proves that the biaxial geogrid manufacturers technology meets the needs of highway subgrade construction, which is beneficial to slow the reflection cracking, improve the fatigue resistance of the roadbed and ensure the stability and reliability of the roadbed.

Keywords: wholesale biaxial geogrid technology; highway subgrade construction; subgrade treatment; biaxial geogrid for sale laying; filling

introduction

The subgrade is an important part of highway engineering construction and a key part of project quality control. As a construction unit and construction personnel, in the construction of the project, we should fully understand the important role of the subgrade project uniaxial plastic geogrid factory price, take effective technical measures in combination with the specific conditions of the project construction, strengthen the quality control throughout the construction process, and effectively guarantee the quality and efficiency of the subgrade construction. wholesale biaxial geogrid is an important construction technology measure, its advantages and characteristics are obvious, to meet the needs of construction and construction, and the application has received more attention and attention.

1. Characteristics of geogrid technology

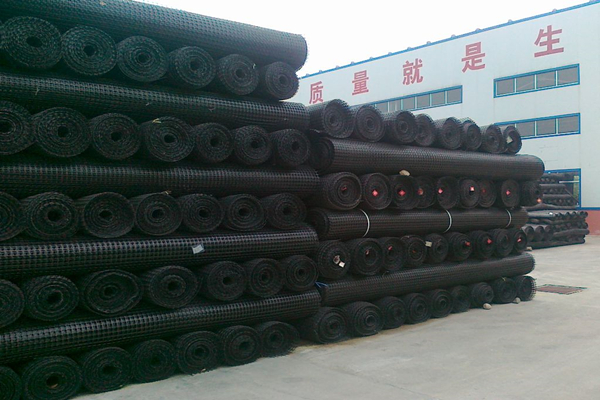

As an important technical measure for highway engineering construction, wholesale biaxial geogrid technology has the advantages and characteristics of high strength, low elongation, high modulus, lightweight, corrosion resistance, high-temperature resistance, and long service life. Therefore, to meet the needs of highway subgrade construction, the application in engineering construction has received more and more attention and attention. At the same time, in the construction of highway engineering, in order to promote the biaxial geogrid for sale technology to play a more effective role, follow the process flow, it is necessary to grasp the construction technical points.

2. Project Overview

The total length of a highway project is 45.3km, which is a standard 4-lane type with a design speed of 120km/h. Among them, the K12+220-K14+350 subgrade has poor stability, small bearing capacity, and is prone to quality problems such as subgrade subsidence. In order to prevent the occurrence of these quality defects and achieve effective control of the project quality, the construction unit decided to use high quality biaxial geogrid technology to carry out the construction of the subgrade project after field investigation and research analysis.

3. Application strategy of geogrid technology in highway subgrade construction

In the construction of the highway subgrade, in order to successfully complete the construction tasks, ensure the roadbed is stable and reliable, and improve the quality and efficiency of the project, the construction unit takes measures from the following aspects to make the biaxial geogrid for sale technology achieve better application results.

3.1 Subgrade processing

In order to ensure the stability and reliability of the highway subgrade and prevent uneven settlement or cracking, it is necessary to strengthen the roadbed treatment before applying the high quality biaxial geogrid technology. It is necessary to pay attention to the subgrade slope control. If it is a high-fill embankment with good foundation conditions, or a fill embankment with a steep cross-slope of 1:2.5 and a slope height greater than 8 m, the wholesale biaxial geogrid should be laid on the subgrade. At the junction of vertical and horizontal fill and fill, if the horizontal cross slope is steeper than 1.5, the wrong platform must be excavated and made into a cross slope of 2% to 4% inward uniaxial plastic geogrid factory price. When the original ground cross slope is steeper than 1:2.5 and the slope height is greater than 8m, it is necessary to fill the junction with the sand with suitable grades to make the transition zone, which will facilitate the subsequent construction. After doing these treatments, it is necessary to lay 2 layers of biaxial geogrid manufacturers at the bottom of the road. The depth of the grille should not be less than 4m. If the fill-and-cut junction is a soil excavation, the soil road must be excavated and then replaced with a qualified soil type.

3.2 Geogrid laying

After the subgrade processing task is completed, the biaxial geogrid factory price laying construction is carried out as required. Pay attention to the quality inspection of wholesale uniaxial plastic geogrid raw materials to ensure the quality is qualified and meet the requirements of construction specifications. When storing and laying high quality uniaxial plastic geogrid, prevent long-term exposure and avoid performance degradation. The uniaxial plastic geogrid for sale is laid perpendicular to the direction of the highway subgrade line, and the lap joint is treated to ensure the quality of the lap joint is good and the connection is firm to prevent loosening. The lap length is usually not less than 20cm, and the strength of the lap joint shall not be lower than the design tensile strength of the material. The quality of uniaxial plastic geogrid manufacturers must meet the requirements of construction specifications and meet the requirements of design drawings. The tensile strength is ≥100kN/m. During the construction process, continuity should be maintained, and distortion, wrinkles, overlaps, etc. should not occur, and the grille should be tightened to force it. The construction workers should tighten it to ensure that the biaxial geogrid manufacturers are flat and even, and close to the lower bearing surface. Effectively meet construction needs. After the laying is completed, the high quality biaxial geogrid is fixed with steel nails to ensure the structure is stable and reliable. It is necessary to ensure that the surface of the lower bearing layer is flat, and the end treatment is strictly carried out according to the requirements, and the embankment filling construction is completed.

3.3 Filling

After the biaxial geogrid factory price is laid, the filling is followed. The filling construction should adhere to the principle of “first two sides and the middle of the middle”. The filling of the two sides should be carried out symmetrically. After the completion, the middle part of the soil should be filled, and the intermediate part filling should not be carried out first. The vehicle is used to transport the packing to the construction site and unload it to the paved road uniaxial plastic geogrid factory price. The unloading height should be controlled within 1m. Vehicles and construction machinery and equipment must not walk on the wholesale uniaxial plastic geogrid but travel along the embankment to avoid damage to the biaxial geogrid for sale. Pay attention to the particle size control of the filler. Generally, the maximum particle size of the filler should be controlled within 6cm and not more than 6cm.

3.4 Rolling grille

When the first layer of filling material reaches a predetermined thickness, the rolling equipment is used for rolling construction. Make sure that the crush is in place to achieve the design density. Then roll the biaxial geogrid factory price back into the package 2m and tie it to the upper layer of uniaxial plastic geogrid for sale. Manually repair and anchor to ensure the structure is stable and reliable, and avoid looseness. It is necessary to cultivate 1m of soil on the outer side of the rolled end to achieve effective protection of the high quality biaxial geogrid, avoiding the occurrence of artificial damage, allowing the high quality uniaxial plastic geogrid to play a better role and promoting the quality of the highway subgrade construction. After the construction task is completed and the quality of the uniaxial plastic geogrid manufacturers are qualified, follow the same process for other layers of wholesale uniaxial plastic geogrid construction. Until all uniaxial plastic geogrid manufacturers construction tasks are completed and the quality is qualified, the upper embankment is filled.

3.5 Problems needing attention

Before the official construction of biaxial geogrid manufacturers construction, in order to improve the quality of subgrade engineering construction, construction personnel should be organized to strengthen the technical norms and standards, familiar with relevant norms and standards and design drawings. Before laying the biaxial geogrid factory price, make sure that the roadbed is level and remove the gravel, garbage, and debris on the surface. Strictly control the maximum particle size of the embankment, not more than 6cm. Pay attention to roadbed compaction control to ensure that the indicators such as longitudinal slope, cross slope, width, and height are qualified. Pay attention to the design of construction drawings, strictly carry out the design and laying of uniaxial plastic geogrid for sale according to the requirements of the drawings, organize the construction personnel to carry out technical disclosure before construction, strengthen management training, improve their awareness of quality control, and strictly follow the requirements. When laying the wholesale uniaxial plastic geogrid, it is manually tightened to ensure that it is flat and even, and close to the lower bearing layer, so that it can effectively meet the construction specifications. Strengthen construction site management, attach importance to quality control, timely repair and deal with existing quality defects, and promote better results for high quality uniaxial plastic geogrid construction.

4. Application effect of geogrid technology in highway subgrade construction

In the above-mentioned highway subgrade construction, through the application of uniaxial plastic geogrid for sale technology, not only the construction tasks are successfully completed, but also the quality of the project is effectively guaranteed so that the project construction has achieved good results.

4.1 Slow reflection cracking

Reflective cracks are common quality defects in highway subgrade construction. The main causes are the shrinkage of the base layer, uneven settlement, and stress concentration of the asphalt overlay. In addition, horizontal displacement caused by changes in temperature and humidity, coupled with vertical shear displacement caused by traffic loads uniaxial plastic geogrid factory price, may cause roadbed cracking. The high quality uniaxial plastic geogrid has a large modulus, which can effectively restrain the stress, release the strain, and improve the tensile and shear resistance of the overlay structure layer. In the construction process, through the application of biaxial geogrid manufacturers technology, horizontal displacement, and vertical shear displacement can be effectively suppressed, the stability and reliability of the highway subgrade structure can be ensured, the reflection cracking phenomenon can be slowed down, and the roadbed engineering construction can achieve better results.

4.2 Improve the fatigue resistance of roadbed

The survey shows that in the construction of highway subgrade works if the biaxial geogrid factory price is not installed, its bearing capacity is often low, and even reflective cracks may occur. In addition, fatigue cracking may occur due to the long-term effects of the load. In the construction of the project, through the application of wholesale uniaxial plastic geogrid technology, the bearing capacity of the subgrade can be enhanced to prevent the fatigue crack phenomenon. In turn, the roadbed’s anti-fatigue ability is enhanced, so that the roadbed can effectively withstand the driving load and meet the vehicle traffic needs.

4.3 Ensure that the roadbed is stable and reliable

In the above-mentioned highway subgrade construction, combined with the basic conditions of the subgrade engineering construction, through the application of uniaxial plastic geogrid for sale technology, not only the construction tasks were successfully completed, but also good results were achieved. After the completion of the project construction, the quality of the subgrade project is qualified, and the various indicators meet the requirements of the construction specifications uniaxial plastic geogrid factory price. It not only effectively guarantees the stability and reliability of the roadbed, prevents the settlement and deformation of the roadbed, but also provides a guarantee for the safe and smooth passage of vehicles. At present, the subgrade project has been in operation for two years, and the quality is in good condition. There are no quality problems such as sinking and cracking, which effectively guarantees the stability and reliability of the subgrade structure. It also guarantees the safe and smooth passage of vehicles and wins the praise of the driver and the people around them.

5. Conclusion

uniaxial plastic geogrid manufacturers technology meets the needs of highway subgrade construction, and it is used for engineering construction, which is not only conducive to the successful completion of subgrade engineering construction tasks, but also can reduce reflection cracking, improve the fatigue resistance of roadbed, and ensure the stability and reliability of subgrade. Provide security for the safe and smooth passage of vehicles. Therefore, the construction unit should pay attention to the application of high quality uniaxial plastic geogrid technology and combine it with engineering examples to effectively use it for engineering construction. And grasp the key points of construction technology, strengthen the quality control of the whole process of construction, and promote the construction of highway subgrade projects to achieve better results.