Application of Plastic Drainage Plate in Soft Foundation Reinforcement

Abstract: This paper takes the strait forum site (A1 standard) boasting land-building project as an example to introduce the soft soil foundation which is more likely to be encountered in engineering construction, and introduces the application of plastic dimple drainage board for sale construction technology in soft foundation reinforcement construction. The situation, and the corresponding quality observation and settlement observation methods are proposed to provide some reference experience for similar engineering construction.

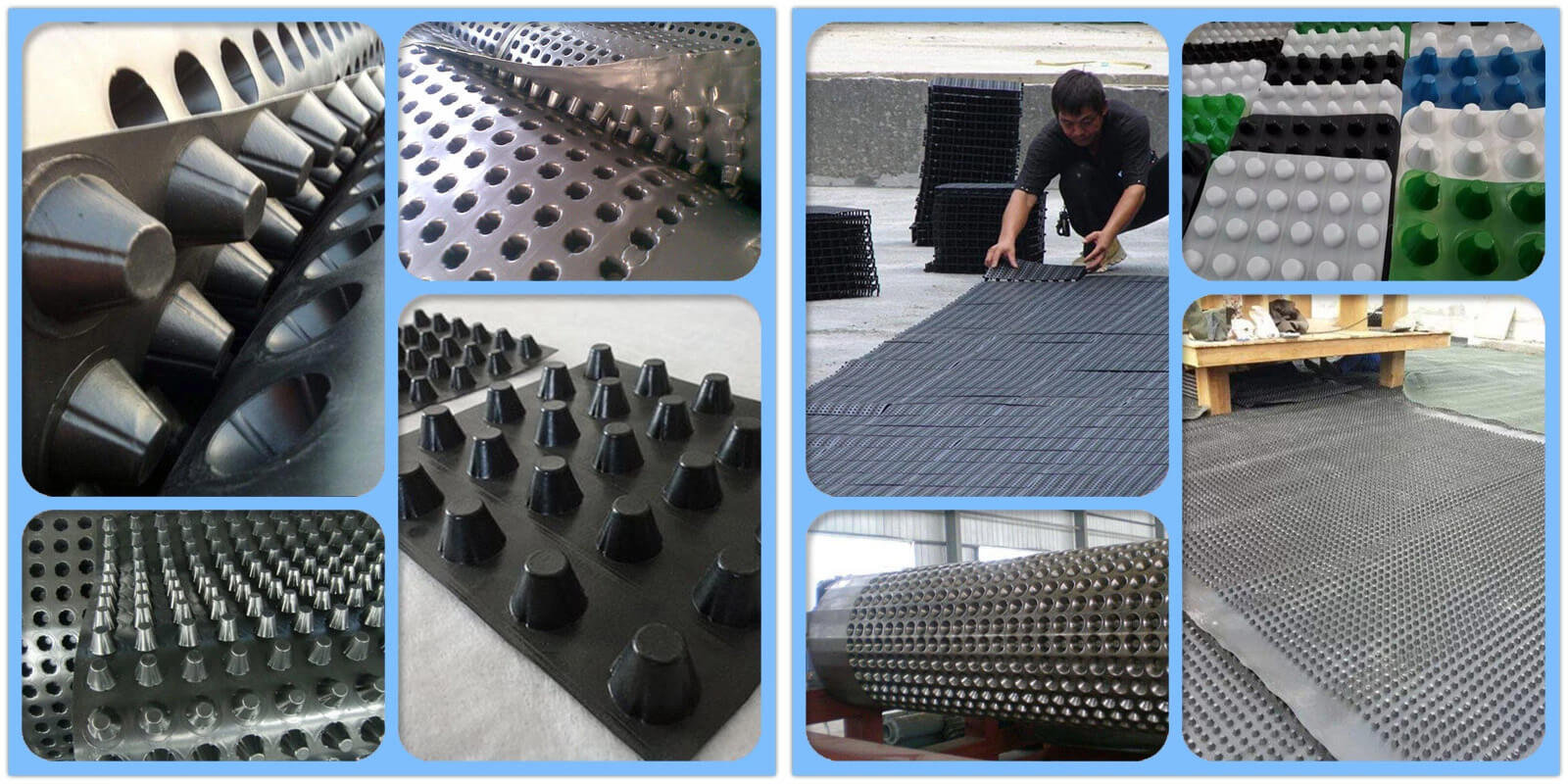

Keywords: plastic dimple drainage board manufacturers; soft foundation reinforcement; application

1. Introduction

In the current process of various engineering projects in China, with the expansion of the coverage of engineering projects, the probability of encountering soft soil foundation problems in engineering construction is also increasing, which brings a great difficulty to the construction. Generally, the methods of soft foundation reinforcement in engineering construction mainly include traditional excavation and replacement, cement soil mixing and gravel piles, but these methods not only have a high cost but also need to use a large amount of construction. Chemical powders, etc., will have different degrees of impact and damage to the ecological environment of the project site and its surrounding areas. However, the soft foundation reinforcement method of plastic dimple drainage board for sale has been proposed for a long time, but the construction process is relatively mature and does not show outstanding reinforcement effect, but it has good environmental protection effect, so it has become the focus of research and improvement. One of the soft foundation reinforcement construction techniques.

2. The construction process of the plastic drainage board

2.1 Project Overview

The Channel Forum Site (A1 Mark) Blowing Site Project is located on the northwest coastal front of Dagu Island, which is separated from the Golden Gate. The project is located on the northwest side of Daxie, Xiamen. The geomorphic unit is the bay tidal flat (intertidal zone). It consists of the tidal flats and tidal gullies of the bay. It is generally a silted section. The tidal flats are mostly gentle mire. The northern salt field is the marine plain. depression. The coastal revetment has seawall protection, the seawall is vertical dry granite slabs, and the back slope of the seawall is 1:1.5, turf protection. The northern area of the seawall was changed to a farm by artificial reclamation. The terrain is wide and the terrain is undulating. There are no landslides, collapses, mudslides, karst collapses, ground fissures and other adverse effects and geological disasters along the coastal revetment.

2.2 Construction process

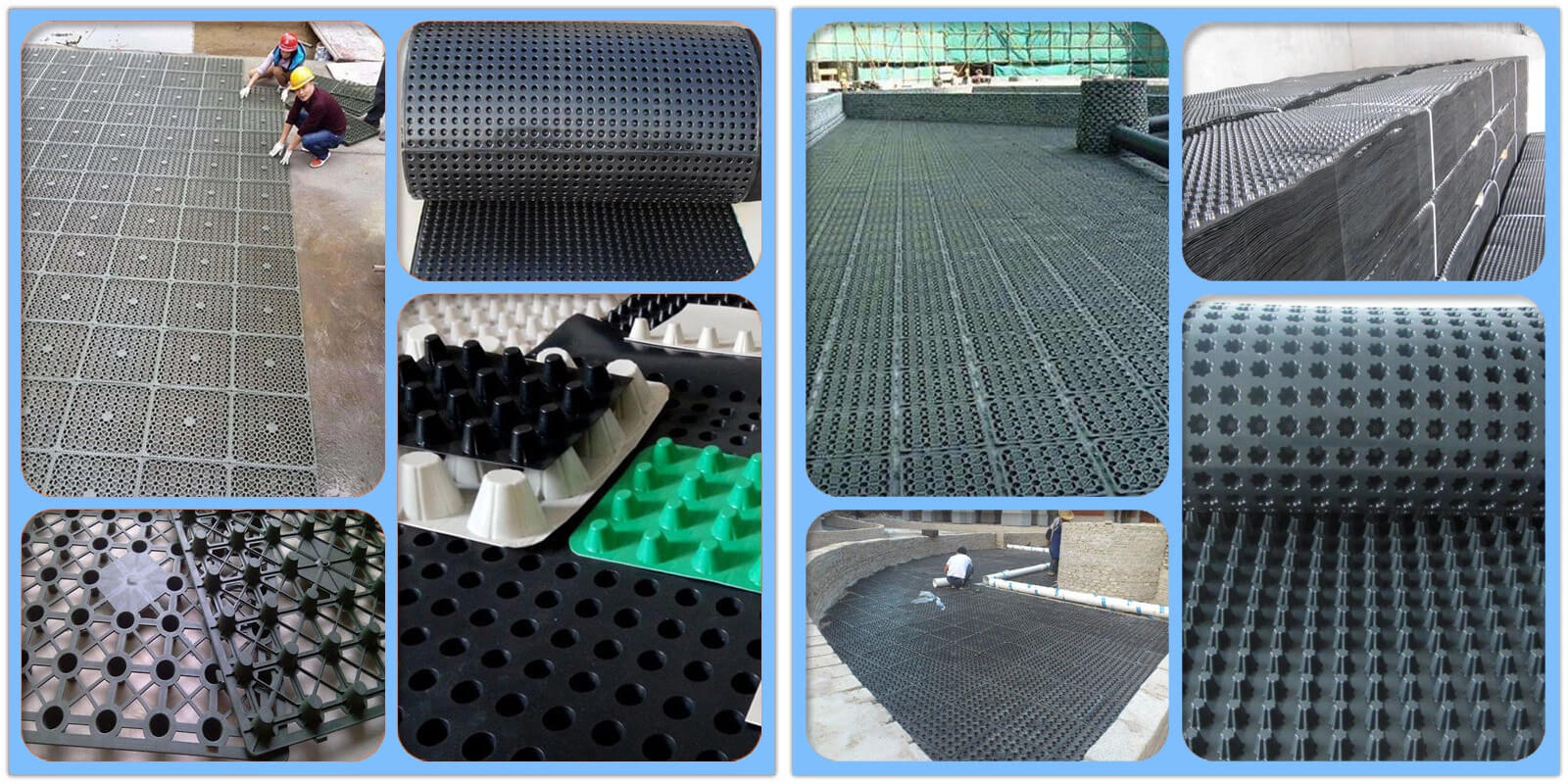

Sand cushion acceptance → dimple drainage board manufacturers inspection, approaching → inserting machine approaching, commissioning dimple drainage board for sale pile position measurement stakeout → inserting machine shifting machine positioning (guaranteeing pile pipe vertical) straight) → pulling up the pile pipe to its lower end off the ground → Install the wholesale storage and drainage sheet pile shoe → lower the pile tube to the elevation → cut the wholesale storage and drainage sheet (exposed 30cm) → move the machine to the next wholesale storage and drainage sheet pile position → return the wholesale storage and drainage sheet pile hole, load the pile boots.

2.3 Construction technical requirements

Before the construction of the plastic dimple drainage board manufacturers, it is necessary to carry out measurement and lofting work. Through this work and through the bamboo piles, the sand cushion layer after positioning is measured and marked to ensure the requirements of the design of the line spacing and the column spacing. After each dimple drainage board manufacturers is applied, the exposed length is greater than 0.2 meters. The plastic dimple drainage board for sale are arranged in a square shape with a spacing of 1.0 m. During the construction, the grid is first arranged at 10m×10m, and the test is inserted at the four corners of the grid to determine the depth of the installation in the grid. It is strictly forbidden to insert the drainage plate into the coarse sand layer to prevent the drainage panel from being inserted into the layer and drain. A plastic film cover of 1 m should be added to the bottom of the board.

The main function of applying plastic wholesale storage and drainage sheet in soft foundation reinforcement project is to drain from the vertical direction. As a more important drainage channel, in order to meet the construction quality requirements, the following aspects should be controlled for the construction of plastic dimple drainage board for sale. The first is to check the specifications, quality, and performance of the plastic dimple drainage board manufacturers before construction, and the materials for inspection should be stacked and covered in accordance with the regulations. Protection work is also required when constructing plastic wholesale storage and drainage sheet to avoid problems such as kinking, breakage and tearing of the filter. The plastic wholesale storage and drainage sheet inserter adopt the track gantry type inserting machine. Compared with other plug-in machines, the track gantry type inserting machine itself is light in weight and can be assembled and disassembled in the construction, which is more in line with the construction site of the project. The actual situation. When the casing is pulled up, the phenomenon of returning belt is controlled. The upper and lower elevation error is not more than 300mm, and the proportion of the uplifting phenomenon should be less than 5%. The overall level of the track is strictly controlled, and the orbit is not displaced or collapsed. In order to ensure the verticality of the casing, the maximum deviation is not more than 1.5%; to ensure the positioning accuracy of the positioning bamboo pile, the plane position deviation should be less than 100mm; strictly control the depth of the installation, each machine is equipped with an automatic recorder, the upper elevation error More than 0.3 meters should be treated according to the waste board, and it should be replenished at 0.45 meters away from it; the track gantry type inserting machine. After the dimple drainage board manufacturers are applied, the exposed length of the head is manually buried in the sand layer to prevent the damage of the head from affecting the vertical drainage.

3. Quality inspection and settlement observation

3.1 Quality inspection

When applying the plastic dimple drainage board manufacturers construction technology in actual engineering construction, it is necessary not only to strictly follow the construction drawings but also to carry out construction and lofting work in strict accordance with the construction drawings. In addition, in the application of this construction technology, it is necessary to check the parameters such as the insertion depth, spacing, and verticality of the plastic dimple drainage board for sale in real-time during the progress of the construction process, and adjust according to the inspection result to ensure the above parameter error. Within the prescribed range.

3.2 Settlement observation

Filling construction is an important part of the construction of plastic dimple drainage board for sale. It is necessary to observe and test the stability and settlement of the roadbed after completion of this link. For the settlement observation, the key observations are the horizontal displacement of the surface, the surface settlement value, and the elevation value, and the filling rate is adjusted after the analysis of the observation results to ensure the stability of the roadbed and construction safety. It is also possible to analyze the late settlement trend by the above results, predict the preloading time and the construction progress of the road surface, and use it as the basis for the amount of earthwork required for subsequent settlement.

In order to ensure the smooth development of the settlement observation work, it is necessary to pre-embed the settlement observation plate before the preloading of the load and the filling construction. In the specific setting, it is necessary to follow the design drawing requirements, every 160m on the route. Make a section setup. The observation pile needs to be set at a position 15m away from the position of the foot at this position, and the settling plate is set at the center of the route, and the observation point is set at this position. Generally, the bottom plate surface size of the settling plate used is 45 cm × 45 cm × 5 cm or more, and when the position of the bridgehead is observed, the cross-section encryption is also required, that is, the observation section is set at a position of 10 m apart from the abutment to improve the settlement. The effect of the observation. In addition, in the process of filling the preloading load, it is first necessary to select the roadbed packing, try to select sandstone and gravel with better water permeability, and adopt layered filling during the preloading process. The stratified rolling method is carried out. In the development of the above observation work in this project, it is necessary to carry out an observation work for each layer of filling and record the corresponding data after the observation. In the observation process, it is necessary to strictly control the loading rate to ensure that it is below the maximum load capacity, and to ensure that the road surface settlement rate of the center of the route is below 15 mm/d, and the horizontal displacement rate of the foot of the embankment is below 5 mm/d. In the course of observation, it is found that the value exceeds the above requirements and the construction needs to be stopped. After one day of observation after adjustment and ensuring that the value is stable, the construction can be continued.

4. Conclusion

In the construction of the project described in this paper, the construction technology of plastic dimple drainage board for sale is used for soft foundation reinforcement. After practical application, it not only shows the advantages of faster construction speed but also lower cost, and also in engineering construction. It will not cause damage and pollution to the surrounding environment. However, it is necessary to carry out the design of specific construction process for specific projects, and to meet certain construction technical requirements, to ensure the soft foundation reinforcement effect of plastic dimple drainage board manufacturers construction technology through a quality inspection and settlement observation, and to provide certain construction for similar projects in the same industry. Learn from.