Application of Geonet in Preventing Reflection Cracks on Road Surface

Abstract: In order to study the application of wholesale HDPE geonet in the prevention of reflective cracks on pavement, geotechnical nets are used in the prevention and reflection of pavement reflection cracks to explore whether geonets have effective prevention and control effects on pavement reflection cracks. The results show that the use of HDPE geonet for sale to prevent road surface reflection cracks can not only change the structural characteristics of the road surface, but also enhance the material strength, thereby enhancing the service life of the road surface, and has good application value in the reflection cracks on the road surface. In this paper, the influencing factors of the cracks on the asphalt pavement are taken as the starting point. The principle of geotechnical nets to prevent the reflection cracks on the pavement is analyzed. Finally, the application of geosynthetics in the prevention of pavement cracks is expounded. Effectively prevent the reflection of cracks on the road surface.

Keywords: high quality HDPE geonet; prevention; pavement reflection crack; application

1. Introduction

A reflective crack refers to the phenomenon of cracks on the pavement due to different reasons. There is a good bonding force between the base layer and the surface layer of the pavement. Through the transmission of the two layers of mutual force, the reflective layer of the crack in the base layer will appear, and then the reflective crack will be formed. The causes of cracks in the base layer are mainly caused by the drying shrinkage of the base material or the vehicle load. They are called temperature cracks and vehicle load cracks. The application of the HDPE geonet manufacturers in the prevention of road surface reflection cracks can enhance the material strength and change the structural characteristics of the road surface, thereby achieving the purpose of enhancing the service life of the road surface. The work of geotechnical nets to prevent reflection cracks on the road surface can improve the performance of the road surface and improve the strength of the concrete material, which will change the road structure to some extent. The factors affecting the reflection crack of asphalt pavement are analyzed. The main analysis is to analyze the climate and vehicle load. When the vehicle is loaded, the pavement is just in the crack state of the base layer, and the asphalt at the crack will form a large stress concentration phenomenon.

2. Factors Affecting the Reflection Crack of Asphalt Pavement

There are many factors affecting the reflection crack of asphalt pavement. For example, climate change, vehicle load, underground capillary water, and unqualified construction materials are the main causes of cracks. The cracks in the base layer are slowly reflected upwards, and the cracks on the asphalt pavement will occur. The main cause of the shrinkage is the change of the climate. When the transverse joints appear, the load of the vehicle will make the cracks deeper. Finally, the transverse joints will spread throughout the whole. The pavement, and as the width of the crack becomes larger, the number of cracks will increase. Cracking on the concrete pavement is caused by the fatigue effect of vehicle load, which will cause the pavement to lose its integrity. When rainwater infiltrates along the crack, the rain will accumulate on the surface of the base layer, and then the top of the layer will gradually soften. The reason for softening the ground of the base layer is also the effect of underground capillary water. In low-temperature weather, the degree of damage of the asphalt concrete is increased by the frostbite of the roadbed or the base layer. Under these factors, the asphalt pavement will not be flat enough, the road surface will be damaged, and the road surface strength will be reduced, which will directly reduce the service life of the asphalt pavement. Cracking of the asphalt pavement will cause changes in the pavement structure and induce damage. At the same time, for the old roads with greater damage, the main method of adding asphalt surface layer should be adopted.

3. The principle of geonet to prevent reflection cracks on the pavement

In the project, there are three main problems in the cracks on the road surface: First, the asphalt is added to the cement concrete, and the layer is cracked at the crack of the cement pavement to prevent the road surface from reflecting cracks. The second is to add a semi-rigid base layer to the crack, which will be reflected by the crack to the surface layer of the asphalt material. The third is to add new asphalt to the old asphalt pavement. The old asphalt pavement will be reflected in the new asphalt in the vertical and horizontal mesh cracks and cracks.

There are many solutions to the prevention of reflective cracks, one is the stress absorbing film, and the other is reinforced. The stress absorbing film refers to a layer of rubber asphalt and special geotextiles; and reinforced refers to reinforcement on an HDPE geonet factory price, glass fiber cloth, and wire mesh reinforcement.

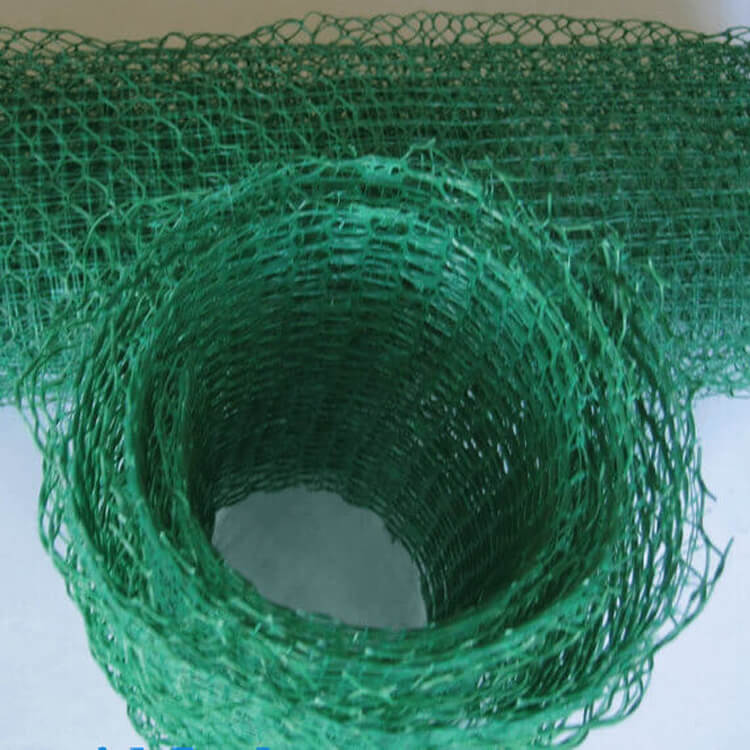

plastic geonet factory price has good engineering characteristics and physical properties, and it has a greater role in preventing road surface reflection cracks and is also widely used in civil engineering. When constructing a high quality plastic geonet for highways, it is necessary to pay attention to slope protection; the second is to carry out reinforced soil; the third is to carry out soft soil treatment; the last point is that the geonet can enhance the structure of the pavement. Anti-rutting and anti-cracking effect.

The mechanical mechanism of the reflective crack directly acts on the cracked part. Therefore, the anti-reflective crack can use the absorption film to reduce stress concentration. SAMI and reinforcement are mechanically different, but the use of wholesale plastic geonet in the prevention of pavement reflection cracks, the integrity of old pavements, and the strength of plastic geonet manufacturers are all related to ASMI.

The geotechnical network has also systematically analyzed the design method of the geotechnical network to prevent the reflective cracks on the road surface and the laying of the plastic geonet for sale. The analysis results show that the wholesale 3D geonet can bear the tensile stress with a large action time or a relatively strong temperature. The stress in the asphalt layer is reduced; it is very effective to lay the 3D geonet for sale in the crack. For example, the drainage groove at the construction joint has a different bearing capacity at both ends of the road. The use of high quality 3D geonet to prolong the damage caused by vehicle loads, although the 3D geonet manufacturers have little effect on the strength and beam specimens, the effect on the load is very large, so the application of 3D geonet factory price in the prevention of pavement launch cracks is very advantageous.

4. Application of Geosynthetics in Preventing Pavement Cracks

4.1. Application of geotextile

(1) The wholesale 2D geonet can reduce the bonding force between the base layer and the top layer. There is an intermediate layer between the base layer and the top layer, and the application of the geotextile reduces the bonding force between the base layer and the surface layer. For example, in the middle layer of the Tujia Expressway, it is concluded that the tensile stress at the bottom of the 7-12 cm surface layer is not reduced by about 20% compared with the road with the intermediate layer, although the interface strength is reduced, but this It is possible to prevent the displacement of the upper and lower layers of the interface and to create a continuous layer.

(2) The anti-seepage layer can be formed, which can prevent the infiltration caused by rainwater in the rainy season, and can prevent the infiltration of the rainwater, thereby reducing the softening phenomenon of the base layer due to being soaked by water. If the rainwater cracks caused by rainwater are infiltrated and under the load of the vehicle, it is easy to cause great damage to the base layer and the surface layer.

(3) In the intermediate layer, the material is highly extensible, and the base layer is cracked by the intermediate layer to make the stress become wider, and then the stress at the crack is concentrated, and the elasticity of the intermediate layer can absorb the cracking energy.

(4) Geotextiles have many functions, for example, they have a certain heat preservation effect, which can slow down the temperature of the structural layer. When laying the geotextile, the pre-tensioning is firstly applied, so that the surface layer can generate a bending moment due to the load, thereby reducing the tensile stress of the load.

4.2. Apply geogrid

The use of geogrid to prevent road surface reflection has been started in the 1980s. According to the relevant situation of the grille in highway application, it is proposed that the geogrid can reduce the rutting by 50% when preventing the road surface from reflecting cracks, and the asphalt thickness is also Can be reduced by 36%. The grille not only reduces rutting, strengthens the surface, but also increases the life of the road. The role of geogrids and geotextiles in the prevention of reflective cracks in pavements is different. In geotextiles, it is a reinforced material that enhances the strength and stiffness of the surface layer and thus effectively limits the surface layer. The geogrid has large holes and does not prevent the softening of the base layer and the infiltration of rain and water.

4.3. The overall application of geosynthetics

2D geonet factory price can ensure structural integrity, reduce rutting deformation, and improve the anti-reflective cracking effect of asphalt. Most importantly, geosynthetics can extend the service life of the pavement. When used as reinforced material, the width of the structural layer can be reduced. Geosynthetics prevent and cure road cracks, although the effect is good, the theoretical basis of geosynthetics lags behind the practice of geosynthetics. The use of the correct construction method is the basic guarantee for the success of geosynthetics.

5. Conclusion

In summary, the China 2D geonet suppliers are used on the road, not only can distribute the load, but also can prevent the landslide, protect the water and soil, and beautify the environment. In order to prevent road surface reflection cracks, when preventing, most of them will be provided with an anti-cracking interlayer between asphalt surface layer and cement concrete road surface. The high quality 2D geonet can be used to prevent the reflection of cracks on the road surface. The 2D geonet manufacturers can ensure the integrity of the structural layer and improve the fatigue resistance of the asphalt material, thereby enhancing the ability of the asphalt surface to reflect cracks and prolong the service life of the pavement.